-

Posts

135 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Everything posted by Dracostan

-

Just had this happen to me - over the Easter weekend of course 😛 Luckily a bit of percussive persuasion got me back home and able to pull the fuse. Checked the motor part number and have a 48700-JF00D - so, early 2013 pre-facelift cars are susceptible too. Lets hope my local Nissan is feeling generous and will do the work under the recall notice. Noticed something else now, the windows won't reset when closing the doors after the opening 'jog' they do to clear the door frame - did I do something in my fiddling about, or are the windows somehow linked to the steering lock action?

-

Looking for recommendations around Cambridge - are Marshalls / E-Tech still on the good list?

-

That must have been lot of work to try and sort the welds, but those rails look so much better than the others. Glad you got them to fit Now, where is the obligatory vid for us ?!

-

Context? Hopefully intentional, rather than some carpark jerk

-

Such a disappointment when supposedly 'engineered' kit has so obvious a flaw - I'm sure you were tempted to take the rails back to OBX in person and beat the designer with them till they fit properly Have you got any other injectors that are longer, to help with the clearance?

-

Such a shame, you got so far into this. Have you considered rotating all the individual throttle body links so they are positioned on the outside of the common throttle bars, and so rotate downward - it would involve adapting/making new butterfly link plates for each TB, but would mean all your hard work won't go to waste. Don't give up on it ......... this has been such an inspiration Draco

-

Having been thwarted recently trying to mod the car, I took it out on my computer and beat my 8+year old Packard Bell breeze block into something a lot more aesthetic ! A sleek NZXT H400i with Kraken x52 cooler loop: Cleaning out my old systems guts to transplant was an experience - surprised it hadn't cooked itself before now ! Gross

-

My Overly Ambitious Idea - Pic Heavy

Dracostan replied to Dracostan's topic in Member Build Projects

Been a bit, but finally got a decent bit of weather in order to stand under the bonnet with tape measure, notebook & pencil and do my best to put a massive crick in my spine Still, my perseverance held and I got a good plan of the clearances around the engine bay, took it inside, fired up the laptop and spent another hour translating it into layout I could lay the intake CAD over.... .... only to find the intake won't fit Bugger. The issue is the dirty great VVEL servo motor hanging off the back of the B bank, that sits right in the way of the horseshoe Now I could go the route of trying to re-orient the servo and get it to point downward out of the way, but I'm not skilled enough to F around with a system as vital as the VVEL control - and handing it off to a shop that has the skills, would involve far more work and time off the road than I can reasonably accept, just for an intake. While I have had a couple of ideas to reconfigure the main plenum body, it would change the aesthetic far from what I was wanting - basically it would be a rounded off version of the stock plenum in aluminium pipe and plate. So unfortunately this is going to end before it could get legs. I feel the look of this would be fantastic and would love to see it realised - So I am offering the CAD files I have to anyone who would like to take this on and tweak it for their own use. Drop me a PM and I'll see about getting the files to you. Thanks for all the support and encouragement, especially from @andybp - I look forward to seeing the progress of your ITBs ! In the mean time, I will have to have a sit and think of what Zeditus itch I will scratch next ! Cheers all. Draco -

My Overly Ambitious Idea - Pic Heavy

Dracostan replied to Dracostan's topic in Member Build Projects

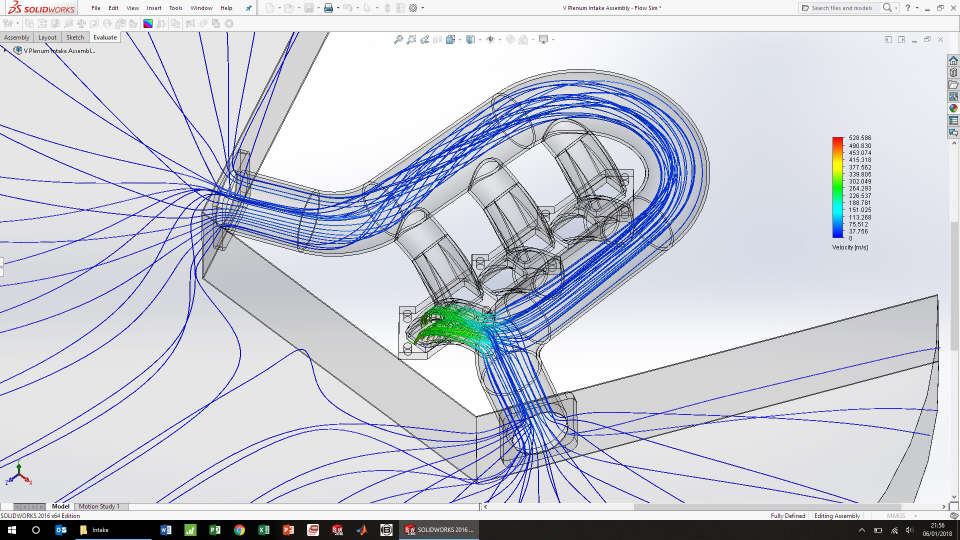

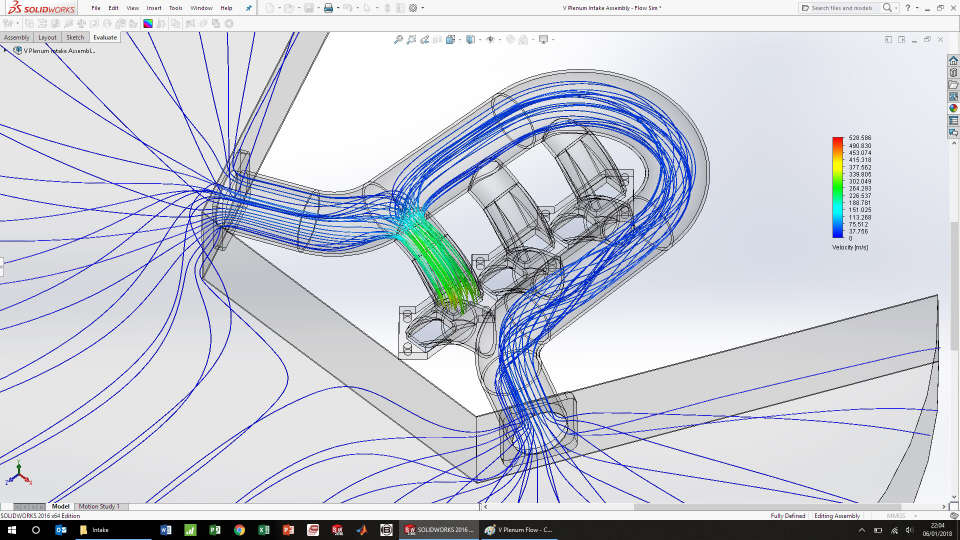

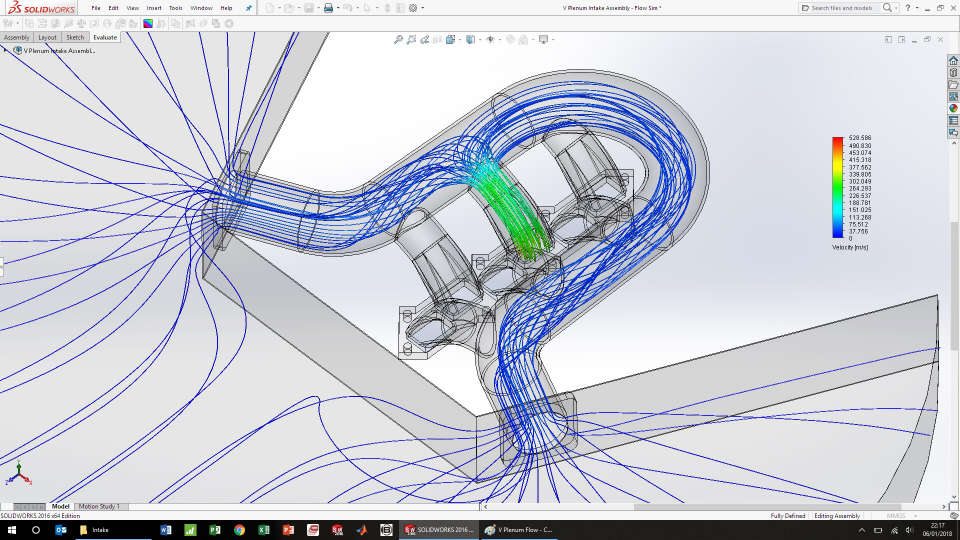

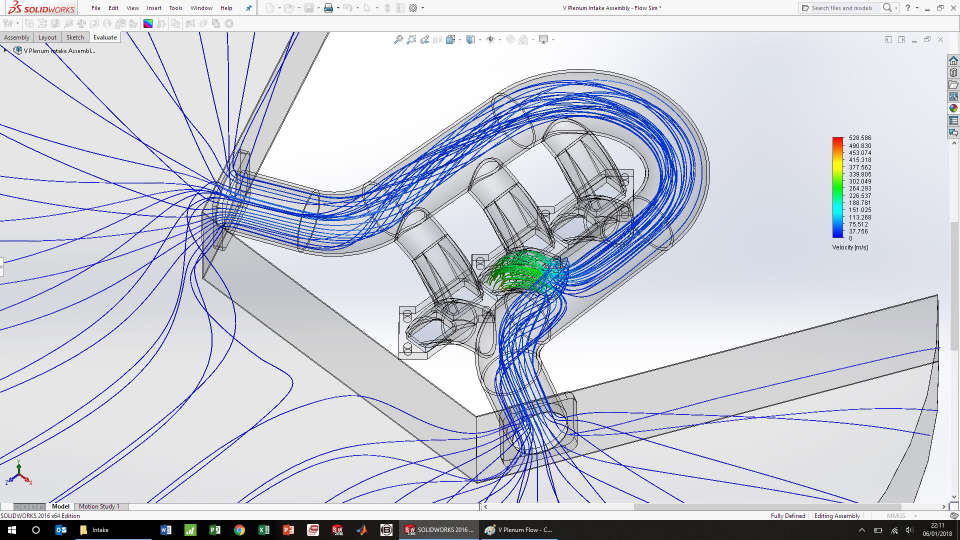

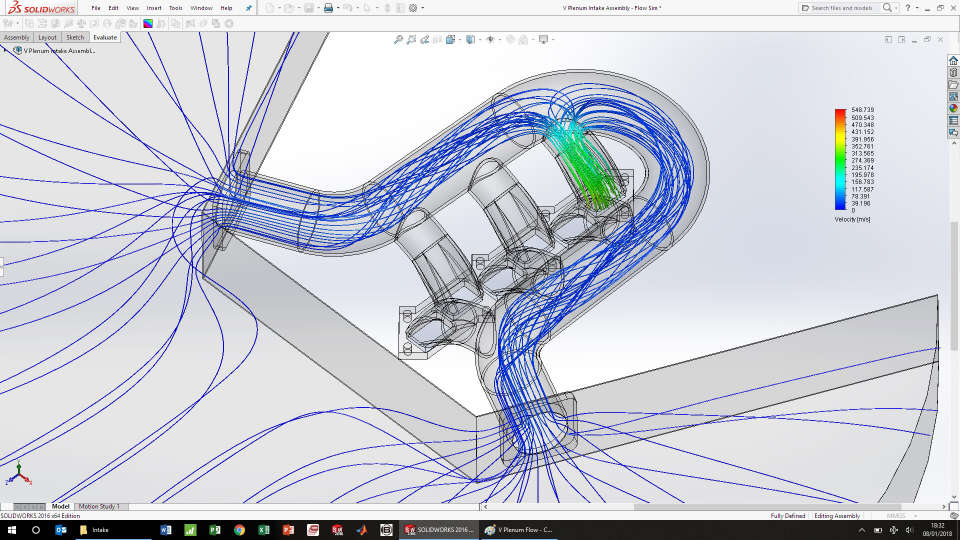

Thanks for the offer, but preferably I'm after a 370 plenum, just to be sure the measurements will be correct. I don't know what the differences are, so don't want to take any chances It's a combination of balancing the draw between the banks and trying to maintain the plenum volume. As you can see in the simulation images, the draw is actually fairly even split each side, no matter which cylinder is drawing. The other reason is - it looks cool ! -

Perseverance man, it'll get there! Think of what an incredible sight and sound it will be when done. In any case, the work you've shown in this thread is an inspiration to the rest of us to up our mod game ! The Zeditus only gets stronger after following quality work like yours.

-

My Overly Ambitious Idea - Pic Heavy

Dracostan replied to Dracostan's topic in Member Build Projects

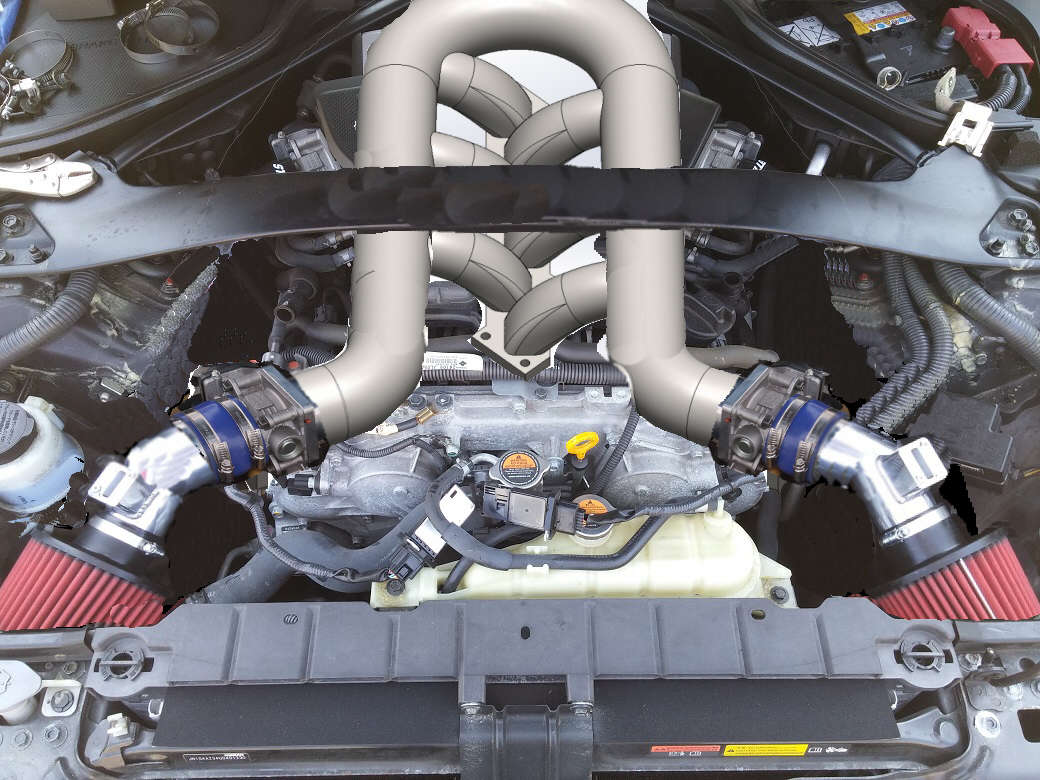

So, after a brief respite from having a tooth pulled out of my head I made a trip to the local plumbers merchants to get some pipe as a guide: That's a 68mm coupler, so also gives an idea of clearance too - on putting it place to see, everything suddenly seemed at lot smaller than I remember! The idea of going to 100m diameter didn't make it passed opening the bonnet The main issue looks like I will have to move the fuel rail damper (the top hat cylinder on the left between the orange topped bolts). Otherwise there should be enough clearance between the oil filler and the cam cover flange. The wiring loom should be able to be tucked down behind the cam cover flange and the PCV pipes will be relocated with dedicated lines to catch cans. Depending on how much of a pain it is to move the fuel damper, I may have to extend the main plenum tube to locate the TBs in front of the cam cover and pointing the filters and TBs further down into the filter spaces: In the mean time, anyone got a spare plenum I could have - PM me a price ! Draco -

My Overly Ambitious Idea - Pic Heavy

Dracostan replied to Dracostan's topic in Member Build Projects

Ok, as promised here are the results of the flow analysis: Cylinder 1 (Passenger front) Cylinder 2 (Drivers front) Cylinder 3 (Passenger Middle) Cylinder 4 (Drivers Middle) Cylinder 5 (Passengers rear) Cylinder 6 (Drivers rear) As you can see they are all pretty much dead on the same in the flow speeds and the flow paths are nice and smooth. I was surprised at how balanced the draw is side-to-side, I thought the front cylinders would draw much more from their respective throttle bodies. Of course does this mean I have a good flowing design ..... or such a restrictive one that each side is equally choked off! Let's go with the first one Next stop will be the local B&Q to pick up some short pieces of 60mm plastic pipe to check the clearances in the bay - I will also get some 100mm, as I think upping the main plenum tube diameter would help with flow and resident volume. I'll be running the flow sim for the larger diameter over the weekend, so I'll throw the results of that up for a comparison when they're done. Draco -

My Overly Ambitious Idea - Pic Heavy

Dracostan replied to Dracostan's topic in Member Build Projects

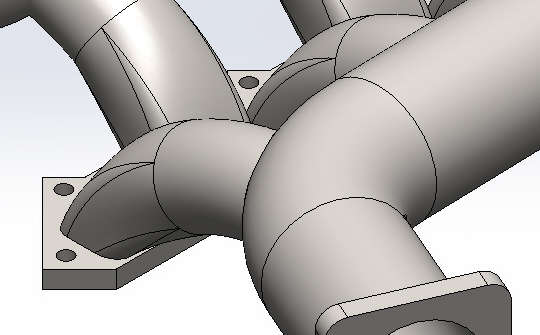

The simulations side of things is moving on! I have managed to build a model that I can use within the fluid dynamics FEA part of my CAD software You have no idea how much pain it gave me trying to close the gaps between the main intake tube and the manifold tubes The model meshing is so accurate it fails on gaps as small as 5 microns ! ffs, but managed to get the joins to match after a considerable amount of copying and pasting between part models. First runs of the simulation look good, nice and linear round the main tube and smooth transition into the manifold with no tumbling over the corners. I will update this post tomorrow with some screen grabs, when I've done each cylinder. In the mean time, while I'm sure I've done good internet research on the firing pattern of the VQ37VHR, I just want to ask here to confirm the cylinder intake draw sequence - in that each cylinder draws individually, with no overlap or 'shared draw' timing (like cylinders 1 and 4 drawing in at the same time). If those in the know of these things would kindly pass on the arcane knowledge ! @andybp Yeah, a used inlet is on the list, just trying to crib a free one first -

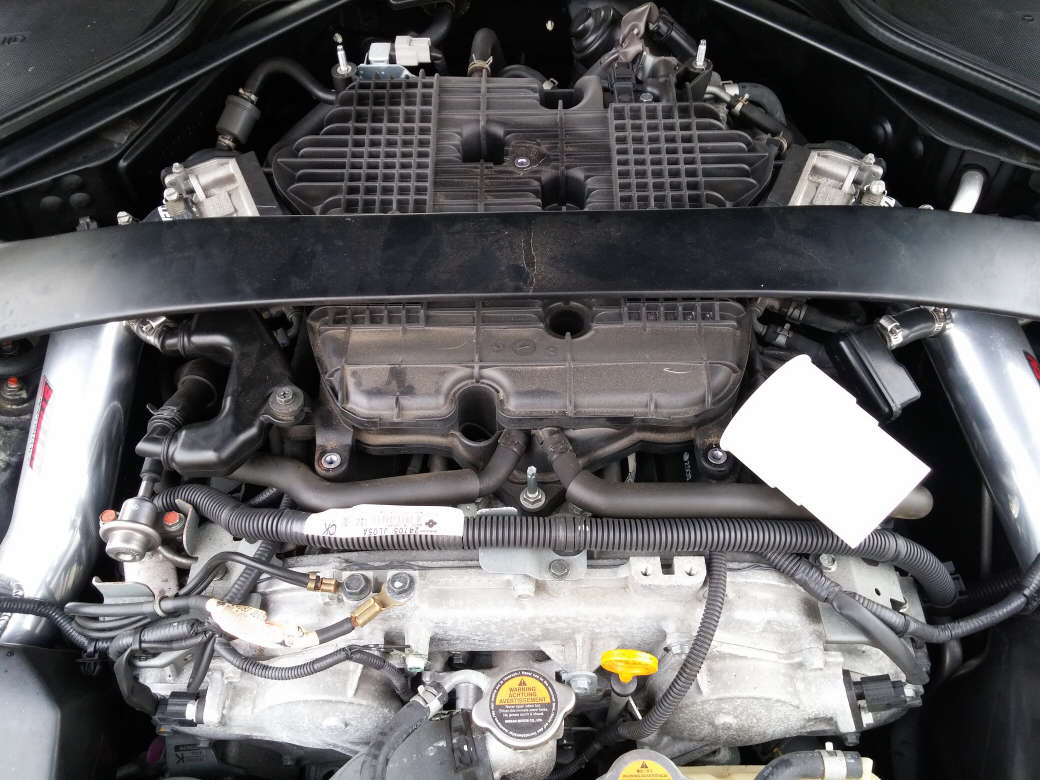

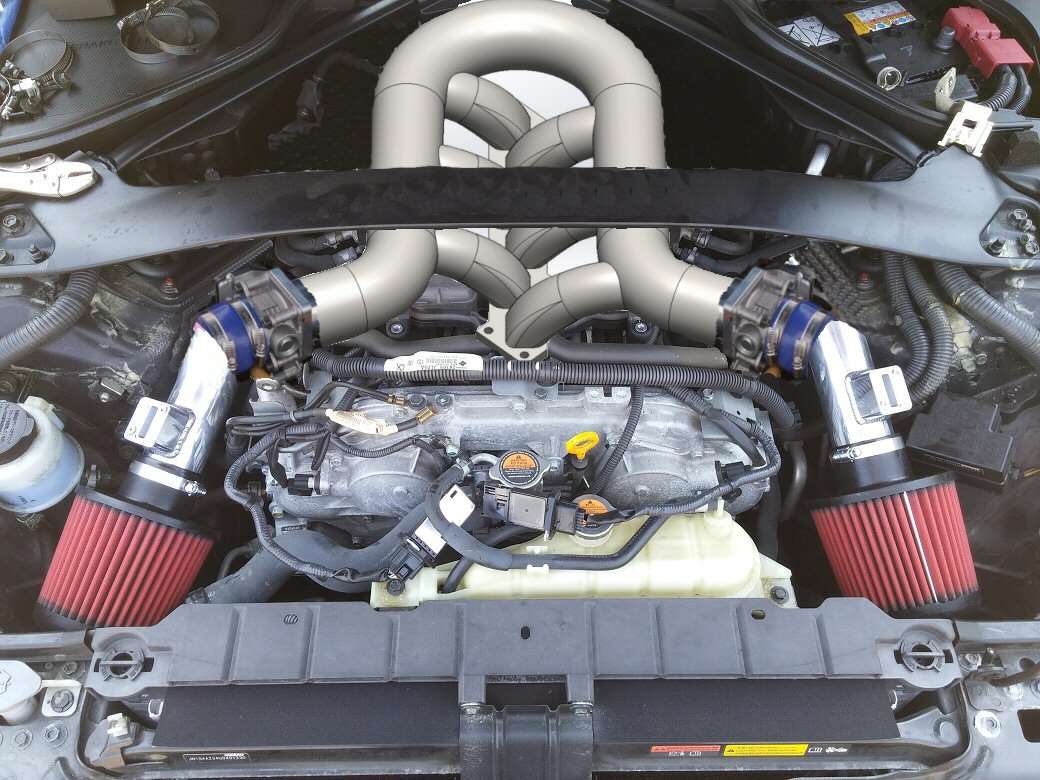

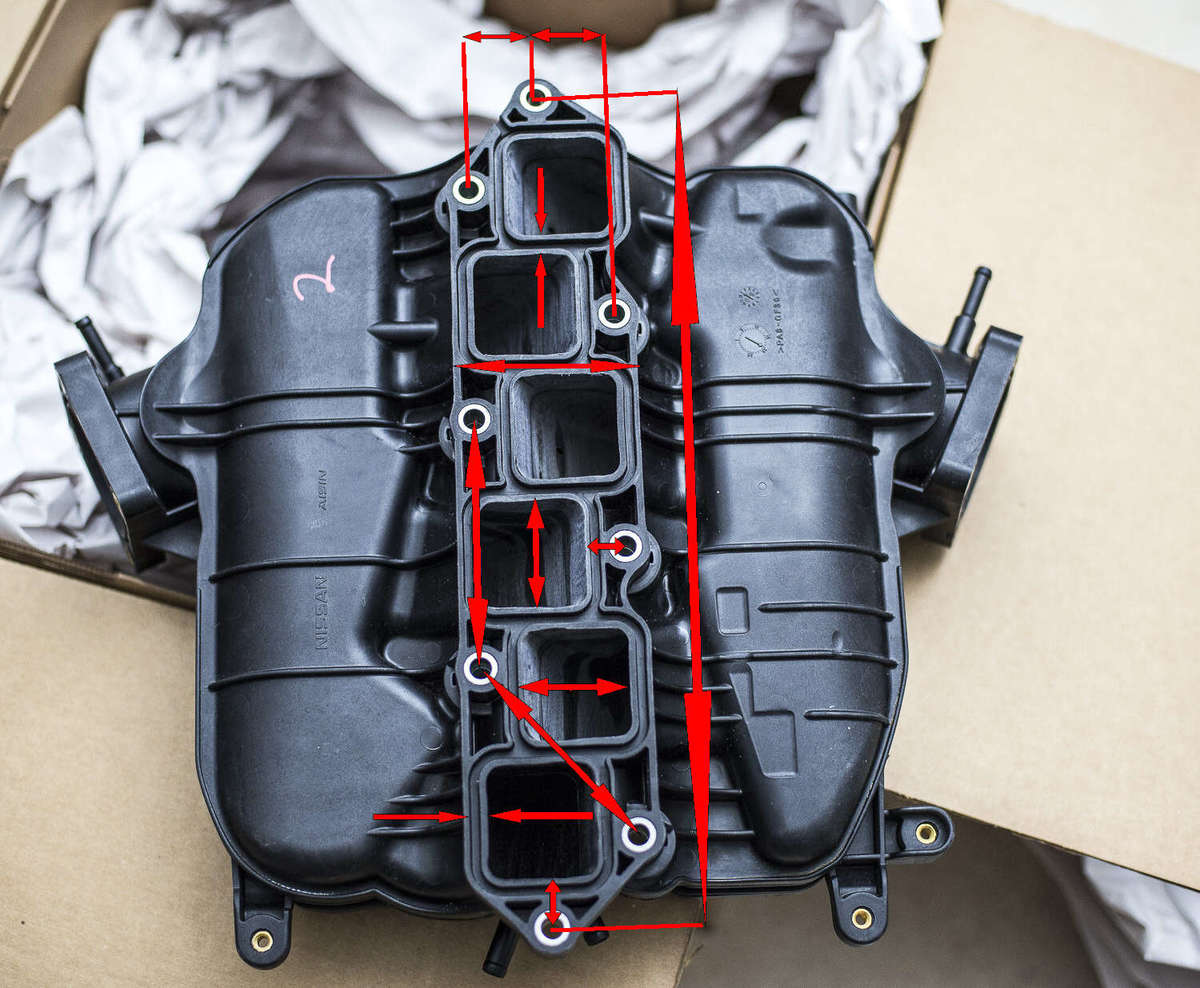

As a few of you may have seen, I have had the idea of making a new intake for my 370Z - taking up a chunk of space in @andybp thread ! Thanks - The idea grew out of the result of me buying a set of Stillen Gen2 intakes, to replace the standard airboxes. I liked the final result and it did add a little underlying gurgle to the engine note that i was looking for. However, my low-level OCD hasn't taken to the mis-matched side-to-side bent/straight tubes - as well as having the Zeditus itch to make my car just that little bit more different ! So, my brain came up with the idea of a full tubular intake behind the throttle bodies to match the shiny short tubes of the Stillen. Jumping on the CAD s/w I have access to through work, I managed to get this to fit together: I figure I can buy in a set of mandrel bent tubes in good quality Aluminium, have the flanges machined up by a local fabricator an tack weld the lot together before sending it to a proper welder to seal up. The end result should end up looking something like this (excuse the crappy Photoshop skills - I'm an engineer, not a graphic artist!) The Zed is my daily, so to get this going, I need to call on someone with a spare intake plenum to get some measurements of the plenum/lower manifold flange (or, lend me one - or best of all, have a CAD model to send me !!) @Adrian@TORQEN @Mark@Abbey m/s @Jez @ H-Dev @Tarmac@TarmacSportz or any spanner wielding good spirit with a Zed in the shed (hint, hint !) The measurements i need to draw up a flange are shown in the image below I know this will be a fairly ambitious build, (and I'm under no illusions that this will be a quick one either), but I think will be so worth it, for both the look of it and the resulting intake sound resonating through a massive tubular plenum space Dracostan

-

Thinking of getting one of the NextBase with a hardwire kit - Where is the recommended permanent live to tie the kit into?

-

Indeed, the horseshoe is for additional volume. I think it will also help balance the draw for the rear cylinders, but that's really a bit of 'finger-in-the-air' fluid dynamics ! The CAD s/w I have does have fluid flow simulation, so I can see what the airflow paths will be - I should be able to simulate draw on each individual inlet port too, so I won't be going at it completely blind. I did think about angling the intake pipes to the airflow, but the space available on top of the engine is a bit restricted by the rear bulkhead of the bay and the cam covers at the front, so I have only a short distance to fit them. I also have a 'W' shaped version that gives more volume and keeps the throttle bodies in the 'OEM position' in the bay, but I don't think it looks as good as the V one:

-

Yeah, the flanges would be CNC, but I figure I should be able to find the 40mm & 60mm stainless tube in pre-bent sections and straights and weld it up from that. Getting the 40mm tubes squared off to match the intake port shape is the bigger issue though. The full piece: I do have a 3D printer, but as the bed size is only 140x140, I think I will have to settle for a miniature of it for inspiration!

-

-

Valy's Zed build #Rocket Bunny >The Blackout<

Dracostan replied to valy's topic in Member Build Projects

At least you had the snow shovel fitted before it came down ...... Oh, yeah that's a splitter -

Link fail!

-

Sooo shiney ... must resist ................. can't afford .................................. it's my daily Help, the Zeditus calls That's going to look stunning - and I'm going to have to get the manifold flange pattern off you at some point. I have an idea for a tubular plenum of some sort!

-

*** TORQEN *** IMPORTANT UPDATE - SEMA SHOW 2017

Dracostan replied to Adrian@TORQEN's topic in TORQEN

The jacked-up Charger, or the super-sized 6-wheel hotrod would be my vehicles of choice for the zombie apocalypse Looks an amazing show this year! Cheers for the pics -

Well, it came to that time of year again,and so another day I had to endure the irrationality of my automotive separation anxiety However, I can only yet again heap praises onto the guys at Abbey for taking care of my pride and joy as it went in for the mini morsel of a P1 and MOT Cheers and many thanks to Mark, Scott & all for their excellent service and quick turn around. @Mark@Abbey m/s PS. Scott was going to send me a quote for diff bush set replacement. Would you PM it to me pls!

-

Better than the shopping list down the back of the front wheel arch! You only have to show them off when the bonnet is open and otherwise only you know they are there! They are a bit 'Well that one will fit there' rather than neatly arranged - but then I'm OCD like that

-

SO jealous of this - if I still had my SX, i'd be elbow deep in a Boss kit and V8 engine swap. Good luck with it, I look forward to watching the progress