-

Posts

3,376 -

Joined

-

Last visited

evilscorp's Achievements

Z Veteran (5/7)

650

Reputation

-

There is no warrenty on the car so IMO find a local garage you can trust, family friends etc or recomendations from people you know. Its harder to find decent garages these days as they are shutting down due to costs of insurance/diagnostic tools etc. Dynatune are good from personal experience when sorting out my shoddy wiring lol, taking my 200sx thing to them a week on friday. Probably one of two localish garages I trust (other is a friend who works/used to own a garage in irvine). However I do own nearly every tool on the planet now so its rare for me to put a car in to get 'Fixed'

-

Busted up bush removed, now just the hard task of finding out who made it in the first place 🤨 Worst case Zmanalex said he could save the day with his old rear housing or I just buff the worst of the damaged part away (two cylinders only the inner layer is fookkddd, it wont oil the same but its not an everyday car and I still have other teething problems to work out probably.

-

Gearbox apart, just need to find out if the bearing has a part number as the two ive used are not correct. Also the bearing is more important than I thought and is oil fed from a gutter and has return grooves to spit oil back into the gearbox.

-

Not used on my Z yet but these make me feel way more safe working underneith my car. Yes I could have made them out of wood but they would have been heavy as hell and take up more space. Not cheap but would recommend. Only issue I had was my trolley jacks were at max height and for some reason (dont think its ride height) I had to do a bit of manual lifting as my first attempt the front right went under ok but the left side was an inch too tall 🤪 These are the 12" version and allow me to actually use a car creeper now rather than cardboard to keep my back off the cold floor.

-

Do these use the same connector as VQ35DE? As I might upgrade my DE ones as these look to face a better direction with the connector for my SR20DET.

-

Been so long since I drove it, hopefully the low weight and 4 wheel drive should make for some brisk driving round my country roads, the 350Z just feels a bit big on the smaller roads in my area and 400ish hp going to the rear wheels is a bit sketchy in the winter/wet. Just having hassle trying to get them to honour the 5 year warranty rather than the 3 year + (up to 10 years) the dealer is now about an hour away so not sure if I will service there or have a local mechanic do it. (Gutted I can't just do it myself). (intend to change the gearbox, diffs, transfer case and engine oil after 1K miles anyway to get rid of the wear-in materials that will be present.)

-

So this finally arrived at the new dealer (18months wait and change of dealer due to Arnold Shark loosing Toyota contract) Just waiting for DVLA to send me a new plate (couldnt resist as it was only £399 for exactly what I wanted) Getting the dealer to PDI aka clean and remove transport films as they can mess up the roof wrap then I will Lanoguard the underside and have a daily driver ready for winter.... Then Jan 2023 I will worrie about how to fit a pram and sh@: inside when our first born arrives.

-

Starting car after while blown headgasket?

evilscorp replied to BurnedSparkPlug's topic in 350Z Technical

More likely just moisture thats built up in the exhaust system, run it for a while and see if it goes away. Head gaskets dont fail often on these only if pushing big power.- 1 reply

-

- 1

-

-

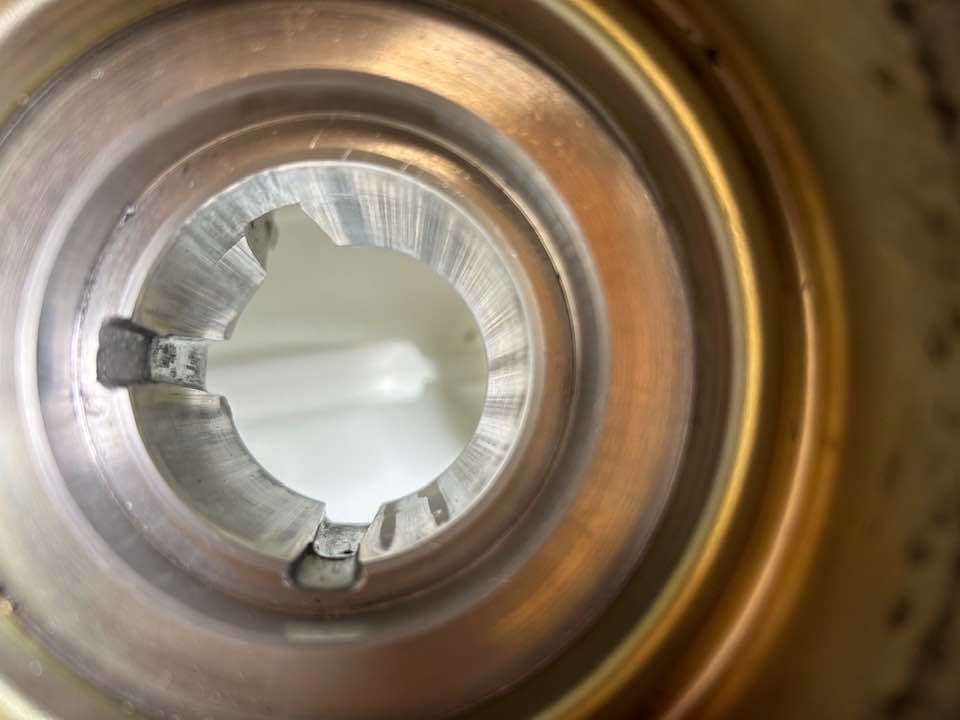

seal out, and damage doesn't look easy to sort/assess properly without the box being apart. sliming down a puller to fit the gap. removed and bashed off some folded over parts but its just too difficult to see down the sides. Gearbox is probably too big to slide out the car while its up on jack stands and I am not sure how easy it will be to remove the tail housing in situ.

-

So it turns out ive messed up my gearbox output shaft collar or something, trying to search through the web to see if it can be lived with or the box is coming out for tear down. Basically when I cut and shortened the 350z propshaft I only changed one of the bearings (they are staked and I wasnt sure if my replacement internal circlip mod would work) the diff U joint was a bit notchy but didn't think it would cause many problems... which bit me in the ass. The sr20det motor is nearly solid mouted (japspeed poly mounts-rubbish) and the gearbox still used the oem 200sx bush which is a bit worn, then the diff is solid mounted. This coupled with the bad u joint has caused the tail shaft of the gearbox to wiggle about during tunning. (the strange vibration we felt) Now I couldn't slide the propshaft back into the gearbox (even though I left 1/2" approx for movement) ended up having to drop the diff at an angle to pull the prop off. This is what I found (minus the destroyed black rubber seal- which needs a small puller or me grinding down a tool). The collar thing around the output shaft is damaged and has a crack, bent areas. The actual shaft looks fine and the slip section on the prop has slight markings but nothing that can be felt with a finger. Anyone know the part number or if its able to be cut down? Need to double check but I assume this part spins with the rest of the shaft and acts as a oil sheild for the splines.

-

Dyno cut short as the carbon propshaft needs balancing, own fault 😑

-

Not sure why sometimes my links to facebook pics work and others dont?

-

Wasted too much time making this, but gave me lots of practice screwing up tig welding. not as nice as the tomei ti exhaust at the back... dont worrie I swapped the standard cat for a new one... which now got so warm on testing something started smoking. ordered a ford heat shield to try protect the passenger footwell as they dont make oem ones anymore.

-

MOT was booked for today.... it didn't make it. Test drive yesterday shows the tune is way off and undrivable, tried a few things but just cant get it happy, still have a few things to check but I can't get my wideband to not read full lean, it was installed correctly but has already killed or had a bad AEM sensor. Going to try get it ready for a transporter to dynatune before MOT next month. Nissan make it nearly impossible to remove the airbag warning light.... and ive run out of time/patience.