-

Posts

842 -

Joined

-

Last visited

G1en's Achievements

Z Fanatic (4/7)

631

Reputation

-

Next Installment from Curborough Events thick and fast now

- 246 replies

-

- waxandshine

- hillclimb

-

(and 2 more)

Tagged with:

-

Its good fun, very fast and flowing but simple. I would imagine its very hard on tyres and brakes if you did lap after lap, especially the front and rear left at Gerrards *if pushing to the limits but definately worth going if you have the chance.

- 246 replies

-

- 1

-

-

- waxandshine

- hillclimb

-

(and 2 more)

Tagged with:

-

Mallory Park Yesterday

- 246 replies

-

- 1

-

-

- waxandshine

- hillclimb

-

(and 2 more)

Tagged with:

-

Just back from first ever visit to Epynt What a Hill Climb Venue! If you have a spare 30 minutes, watch the Zed flying up the Brecon Beacons.

- 246 replies

-

- 1

-

-

- waxandshine

- hillclimb

-

(and 2 more)

Tagged with:

-

And onto Sunday (Part 2 of 2)

- 246 replies

-

- waxandshine

- hillclimb

-

(and 2 more)

Tagged with:

-

Latest Vid from Blyton Park - Part 1 of 2 (Saturday)

- 246 replies

-

- 1

-

-

- waxandshine

- hillclimb

-

(and 2 more)

Tagged with:

-

Yep, same here, makes the world of difference when your lying on the driveway with limited space trying to undo 15 year old bolts. can confirm, brakes are now mega. Bedded them in with a drive today, was decelerating from 90 to 20mph in what seemed like 40mts. same amazement as when i put the carbon lorraine and rpx race pads on so they should save me a few tenths.

- 246 replies

-

- waxandshine

- hillclimb

-

(and 2 more)

Tagged with:

-

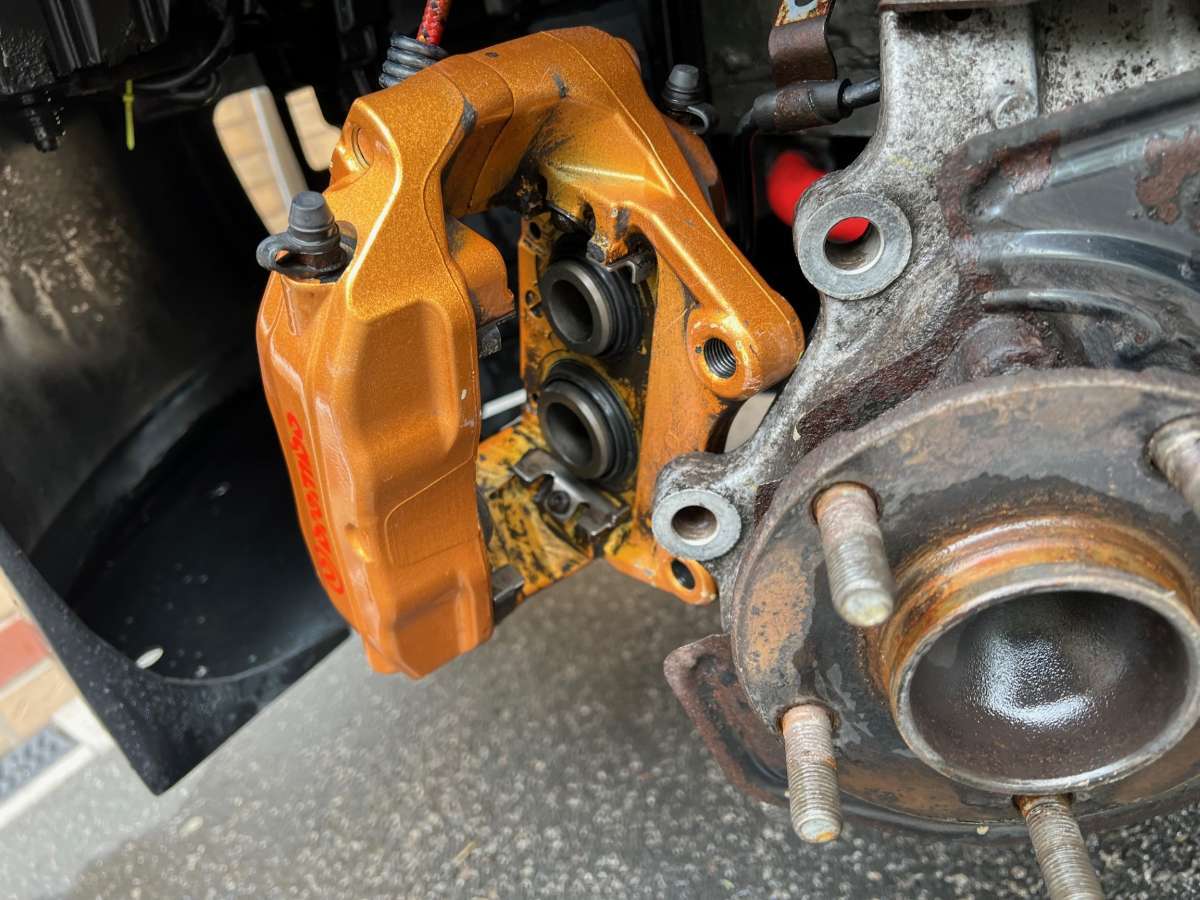

New * Discs and Pads all round today as the current ones were getting very tired and worn. And when your at maximum attack on track the last thing you want is to be attacking the wall because you can't stop. Products of choice this time were the black diamond grooved discs, same as previous as they have done over 2 years with no issue and they are very competitivly priced, cheaper than other options at just over £200 pair. They are now owned by ProBite so not sure who actually manufactures them now but either way a good solid disc. Front Pads, I have opted for the PBS Procomp S1 compound. I have heard lots of good things about PBS so thought I would give them a try, Gone for their most expensive option because most expensive equals most bestest obviously. Now the ProComp pad is available in 4 different compounds but only the S1 is offered for the 350z brembos which is ideal for me as thats the one I need. Its designed more for sprinting and shorter races, works from 50c (so almost stone cold) and offers top level friction coefficient of 0.5 accross full temperature range upto 800c. Rear pads, I am using some EBC Yellowstuff I have had in the garage sat around, They have been used before but are only around 20%-25% worn so thought make the most of them and save some money. I also bought a caliper tool to wind the pistons back as I thought my usual technique of shoving a hammer in and using the disc as leverage will come back to bite me at some point. So onto the left front, like I sad, discs have seen better days. Removed the caliper and gave it as good a clean as i could in the time i had without going too crazy. I should have taken a before pic as they were caked inside with brake dust after nearly 2 years of driving and race events. New discs on, new pads in, every bolt and thread copper greased up, I don't wether you should copper grease some threads or wether its the right thing to use, but it does mean everything comes off nice and easy when you want it too, I didn't have any problems what-so-ever this time because i copper greased everything last time! Front pads were not down to the backing plates like i thought but only had around 4mm left so were definately getting low. I always assume the insides that you can't realy see will be worse (because as some of you might know) the brembos seem to wear the inner pads quicker than the outers, there may be some logic to it, the inner pistons are closer to the flexis/hard lines so get force? who knows but because I inspect the pads every year when the season finishes I had swapped them around last time which meant that over the 2 years ish the wear was more or less uniform. Onto the front right, dust shield looking very corroded but still attached, again cleaned up caliper best i could. And new product behind the wheel: Onto the rears, didn't take any pics really as its more or less same as the front, the rear discs are a little tricky to get off as anyone who has changed their 350z brakes will know, they tend to catch on the internal handbrake shoes but a little patience and wiggling and a mallet and they come off. The rear discs and pads were certainly overdue for changing. Disc below with a noticeable lip, probably worn more than recomended, so much so the grooves had started wearing out so were not grooving any more. And Similar story with the pads, only around 2mm left on them. pic below next to the yellowstuff, I was suprised that the yellowstuff pads had a significantly smaller pad face area but as its the rears should be fine. Rear Discs and pads all complete. Looking forward to feeling the difference in this setup. Will bed them in tomorrow as i'm ready for bed after doing this.

- 246 replies

-

- 6

-

-

- waxandshine

- hillclimb

-

(and 2 more)

Tagged with:

-

Blyton in 4 weeks, bit of a wait now.

- 246 replies

-

- waxandshine

- hillclimb

-

(and 2 more)

Tagged with:

-

Harewood Hillclimb - Sunday 13th April 4th in Class

- 246 replies

-

- 2

-

-

- waxandshine

- hillclimb

-

(and 2 more)

Tagged with:

-

Part 2 Sunday

- 246 replies

-

- 1

-

-

- waxandshine

- hillclimb

-

(and 2 more)

Tagged with:

-

Back to Anglesey for a fantastic weekend Part 1 of 2

- 246 replies

-

- 2

-

-

- waxandshine

- hillclimb

-

(and 2 more)

Tagged with:

-

Its been a long 5 months for the Zed parked up in the garage but yesterday she got to stretch her legs again on track and get my heart rate up. First event of the season at Cadwell Park. Enjoy!

- 246 replies

-

- 3

-

-

- waxandshine

- hillclimb

-

(and 2 more)

Tagged with:

-

Thanks Fella, I guess i am a fairly quick/talented driver but so are a lot of other people in motorsport. I have definately improved massively from when i first bought the Zed, i remember my first couple of events being all over the place and on the grass more than tarmac, it's a whole new ballgame trying to find the limit of a car (and your ability) than regular road driving but the 350 comunicates so well as an old school rwd car, especially with all the mods I have done over the years. Not sure which bushes I have changed, I know I have done most of them front and rear (to polybush) as i have changed parts over the years. Best pressures I found for the AD09 tyres were around 30 front, 26 rear (cold pressure) going up a couple of psi over the runs. a fair bit lower than other tyres I have had which are normally 33F/30R but my setup will be different from most other Zeds as its been tweeked to exactly how I want the car to handle over the years with camber/toe/reide height etc.

- 246 replies

-

- 1

-

-

- waxandshine

- hillclimb

-

(and 2 more)

Tagged with:

-

Seeing as its Christmas Eve, might as well do a run down of the year (best as i can remember) 21 Rounds/Events in total were completed competing in 3 main Championships. HSA (Hillclimb and Sprint Association) BARC (British Automobile Racing Club) NSCC (Nottingham Sports Car Club) The car has performed admirably again for another year but not without a few problems. The Radium in tank fuel surge pump has proved a total PITA all year, now it may not be the systems fault entirley as i think the fuel tank opening in bowed but after multiple attempts i think i have eventually sealed it, although a still get whiffs or petrol every so often so their may be a fitting elsewhere weeping but at least the big hole at the top is sorted. fingers crossed. I also had issues with the clutch/gears for the last few events which turned out to be another clutch failure, seems whatever i use, they can only hang on for 2 years. Then another thing that plagued me for most of the year was my tyre choice. going from extremes and A052 that are ultra soft to a AD09 tyre that is more road and endurance focused (relatively speaking) proved very frustrating all year, especially on the venues where i had been previously and just couldn't match the times with these tyres no matter how hard i pushed. The fact that the previously mentioned tyres wore out in around 15 events and these still had 5mm of tread left after 21 events kind of emphesizes the hardness in comparison. So I recently put my hand in my pocket and purchassed another set of the good stuff for next season. So going through the season was a mixed bag of highs. lows and anywhere in between but ultimately finished with some silverware and the car mainly intact, it did fail its MOT last month for the first time ever. The rear quarter I had replaced after my big crash at Aintree a couple of years back was not quite as rust free as my original car and the cill towards the rear arch had succombed to the metal worm, luckily, after removing the side skirt, it was only the last few inches or so and the rest looks solid, so a bit of cutting and welding some new metal in was all that was required to get it through, nothing else needed, good for another year. So highlights were 11 class wins over the season lowlights being when i was 2 seconds adrift from my prev times at certain tracks I still managed 6 new PBs despite the inferior tyres Results Below: Cadwell Park 101.5 - 2nd Anglesey National 62.99 - 3rd Anglesey International 103.6 - 2nd Blyton Eastern 79.47 - 1st Blyton Outer 72.40 - 1st Coventry Motofest 73.01 - 1st Coventry Motofest 71.46 - 1st Curborough Figure 8 66.62 - 2nd Mallory Park 84.74 - 1st Curborough Figure 8 65.64 - 1st Curborough 2 Lap 65.57 - 2nd Harewood Hillclimb 66.63 - 5th Harewood Hillclimb 72.40 - 1st (WET) Loton park Hillclimb 61.00 - 2nd Snetterton 100 122.93 - 1st (WET) Snetterton 100 102.08 - 1st Hethel (LOTUS) 90.66 - 3rd Blyton Eastern 77.15 - 1st Blyton Outer 72.68 - 2nd Curborough 2 Lap 65.03 - 4th Curborough Figure 8 66.81 - 1st So onto the final standings and results for the year, I have had the NSCC and HSA awards presentation, the BARC awards are in March so not recieved my trophey as yet but results as follows: HSA 5th Overall in Main Championship and winner of the Oppenheimer sub award NSCC 3rd Overall in Main Championship BARC 2nd Overall in Main Championship Award to follow Plans for next season, I am leaning to doing the same 3 championships again, you build up a good repor and commeradery with people as well as friendly competition. I was thinking about doing the classic marques championship but this is seperate to all others and would mean (i think) you cant score points for multiple championships at the same time so I would have to commit to that and sacrice all others (unless i literally did almost every weekend racing which isnt practicle or marriage compatible!) just need to check the relevent regs. I have provisionally drawn up a schedule to include all my regular events but 2 new additions. Epynt in Wales (Brecon Beacons) which i have never done and looks fun, and also Scammondon, local to me and never previously done as its very short and i tend to steer clear of the shorter ones as in my head sprinting/hillclimbing is expensive enough but only doing 30 second runs instead of 60 secs means its even twice as ludicrous! No other plans to modify the car, just looking forward to pushing it the the limit as always, done a major service to end the season:m Diff Oil, Gearbox oil, Engine oil, oil filter, brake fluid and clutch fluid so hopefully she will be running sweet come March. Also for the detailing geeks, got this bundle in the black friday sales to keep her (and the rest of the fleet) looking tip top. Final few shots from the HSA awards which was held at the national motor museum at Gaydon: Have a very Merry Christmas everyone If your bored over the festive period, watch some of my videos from this season, they will send you to sleep in no time!

- 246 replies

-

- 5

-

-

- waxandshine

- hillclimb

-

(and 2 more)

Tagged with: