-

Posts

1,355 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Everything posted by andybp

-

Sorry Dan we just fell out and it's not over the poop chute "on the Eighth day god created coffee" I suggest you mend your wicked ways blasphemer any way back topic I use a delonghi Expresso machine with ESE coffee pods all the taste huge variety good price and no mess https://en.wikipedia.org/wiki/Easy_Serving_Espresso_Pod

-

still got a little more machining to do on it so I might de-toblerone it but it's not a priority

-

Lots of aging mechanical equipment outside doesn't tend to like the cold,snow,rain,sun or even a light mist one old line shaft pump I was looking at the other day was made in the 50's runs about 15 hrs a day 365 days a year they don't make em like they used to.

-

The ports are all smoothed and finished now and I've started machining the arms for the throttle linkage hope to get some more done this week but it's supposed to snow and I'm on standby

-

Anyone know the thread size of the factory oil temp sensor? ?

andybp replied to Rob350's topic in 350Z Technical

I think it's M12x1.5 not 100% sure though -

It's a damn shame I wanted to see this it was going to look really cool' so over to plan B I expect to see a proposal on my desk by monday.

-

No phenolic spacers how can you live with the shame just to tease you some more here they are all bolted down clearances aren't too bad either I've now removed my throttle bodies and fitted the original plenum as it's easier to take on and off so I can still use my Z and yes I know I need to change the date and time on my camera and take the plastic off the lense

-

yea I saw it price starts at £2400 including vat by the time you add on all the bits you actually need to make it work it's up to £3300 plus the ecu at another £1000+ ignoring my time it's cost me about £350 that will probably hit £400-450 + the ECU by the time it's finished and I wouldn't have had all this fun so Jenvey £4500 Andybp £1750

-

At the end of the day NA tuning won't gain you a lot of power even if you throw money at it the power increase for your money will be minimal compared to forced induction if you're being sensible then plenum spacer decent filter in the stock airbox or an induction kit for inlet and high flow cats a decent exhaust and a remap and you're done but even that can be expensive your biggest gain for that work will be the smile it puts on your face due to the sound and improved response (and yes I know I'm not one to talk about being sensible )

-

if it doesn't come with it from the factory it's a mod, weather you declare it or not is up to you it's your risk if the insurance find out the very least they will do is make you pay the additional premium or they may cancel your insurance modifying cars is an expensive business if you can't afford the premiums dont mod it. Preaching over at the end of the day your risk, your choice

-

Thought I'd try to get some work done today I recently bought a new belt finger sander / power file whatever you want to call it also a bucket load of belts for it and 6 flap wheels so far I've got through 25 belts and all 6 flap wheels wish I'd bought softer ally for this manifold never mind I think I'm nearly there another hour and 10 more belts should see it done

-

Have to say I'm not a fan

-

As Headphones said you should really check the code it may be important get the code post it up here someone will tell you if it's important

-

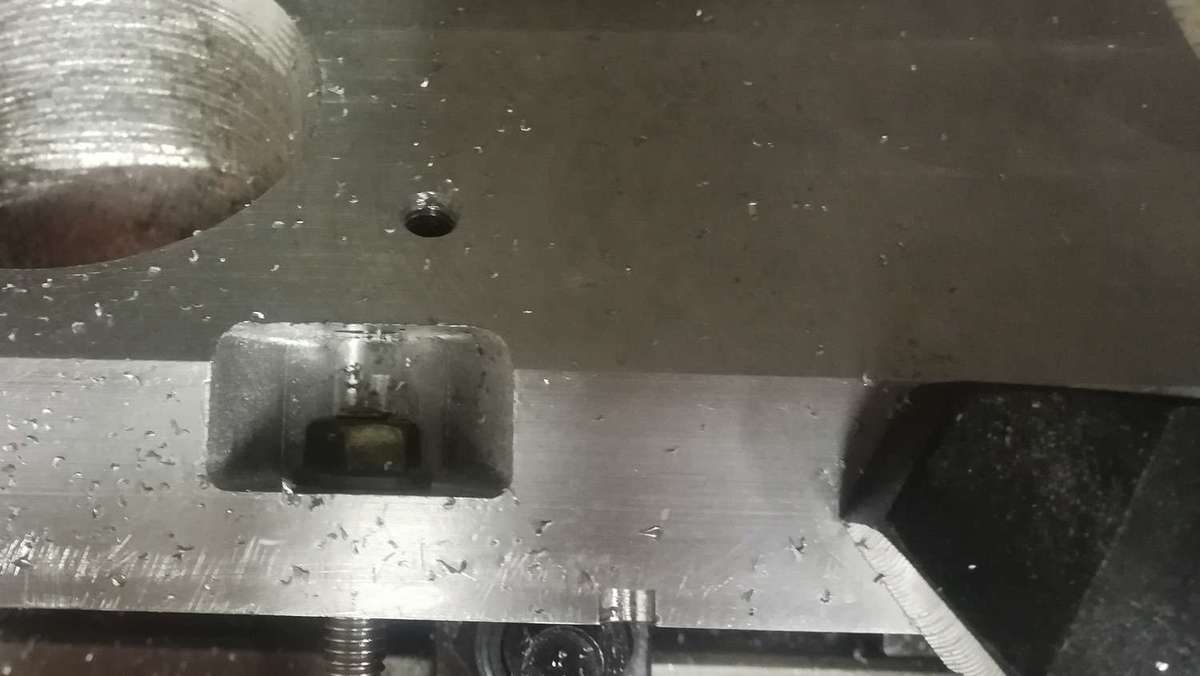

All of the 10mm phenolic spacers are cut and the thing I haven't mentioned so far, which is how I plan on bolting my manifold to the inlet manifold is sorted successfully the problem was that the mounting bolts for the throttle bodies and the manifold both wanted to occupy the same space so my solution is to cut a shaped pocket into the manifold below the throttle body mounts just big enough to get the nut on the mounting stud and get a ring spanner over the top I've still got the three pockets to cut on the other side and I still need to smoothe the ports so I guess I'll keep putting one foot in front of the other for a while yet

-

New thicker 10mm Phenolic spacer has arrived and I've cut a couple already the new one allows for a much smoother transition in the port shape compared to the 6mm material as can be seen in the pic below

-

my thoughts exactly

-

also the term " computational step to far for your setup " doesn't really apply as I mostly program directly in Gcode so no fancy cad/cam setup

-

Perfectly reasonable question surprised nobody picked it up before, I did consider this and it could be done with the right tooling (which I don't have) but it was hard enough programming a curve into the port to blend into the port from the manifold while blending an elliptical port into a round one but to get the elliptical port to change in both width and height blending into a round port while creating a curve into the port was just too difficult so I chose to blend the port height within the insulating spacer that I was going to use anyway

-

Yea I know bloody dog (I might have to get a dog now to make that believable I think I'll call him Gary ) I might be moving down past you this year the missus has just applied for a job in Bodmin I've been looking at jobs myself but nothing has grabbed me so far.

-

close to a test fit have you not seen how slowly I work but on the bright side the 10mm phenolic sheet showed up today so at least I can get on

-

Jwt oil pan spacer useful for track??? Any advice??

andybp replied to Rob350's topic in 350Z Modifications

Just checked one of my posts it's been on for 2 1/2 yrs no leaks no problems can't remember where i got it but may have germany I seem to buy a lot of stuff from germany or china and have very few problems -

Jwt oil pan spacer useful for track??? Any advice??

andybp replied to Rob350's topic in 350Z Modifications

This is the same as the one I bought good fit no leaks and my oil pressure went up which I can only assume was due to lower oil temperature -

Haven't had much progress lately as I've been writing the gcode for the phenolic spacers/gaskets but I'm happy with it now, so when my new 10mm sheet shows up I can get these cut. The test ones I've cut are only 6mm and the 10mm will allow a smoother transition between the BMW oval and the manifold round port shape

-

I've had some interest in what my plans were for my current setup once I get the new one running so this is a reply to your message and others who have shown interest it would need a throttle servo since I plan on using some parts of mine or you could get me another one and have mine and an ecu similar to my link g4+ that can tune either using alpha N or speed density(which I use) an iat temp sensor a manifold to distribute the vacuum, modifications to the ventilation system for the fuel tank and a lot of patience oh and some one to tune it but you have to bear in mind this is far from perfect not to production standards as much as it seems to work perfectly well. if you already had a capable ecu (which is the biggest cost ) I'd say give me the cost of a servo and a drink and it's yours to buy a new ecu specifically for this project is not something I would recommend

-

No I haven't but then I only have a tiny little garage to work in and a dinky little milling machine unlike some people and I've had man flu and the dog ate my homework