-

Posts

1,355 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Everything posted by andybp

-

I could let you have my old setup but it'd still cost you another £1500-2000 to make it work

-

I thought we spoke about you not giving away my plans and secrets you've already blabbed about me turning base metal into gold and besides you know the time machine is next on the list

-

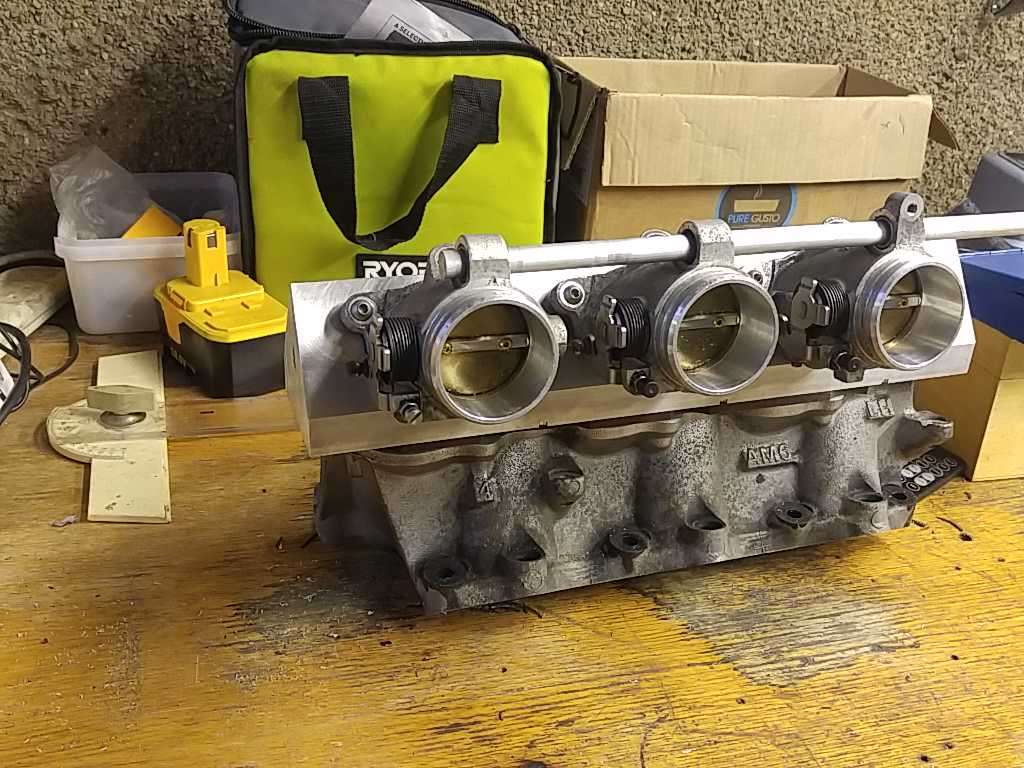

It may be coming together but there's still a lot to do I have to make the Phenolic spacers and I haven't written the code for it yet, still some machining to be done on the manifold for the mounting bolts, still got to smooth the ports that's gonna take a while then I need to make a new throttle servo which I'm going to make from scratch this time, seems never ending and what's worse it's all self inflicted Oh well I'll just have to start putting one foot in front of the other as they say.

-

got the other bank finished today still lots to do but the scary bit is over without too many problems hopefully I can get the ports smoothed out this week

-

well one side is done other than I still have to smoothe the ports Should get the other side done tomorrow then I have to make up the 8mm phenolic spacers the throttle bodies will actually mount to so lots to do yet.

-

I was indecisive now I'm just not sure!!!! Over to you lot

andybp replied to Keyser's topic in Off Topic Discussion

As I see it your 370 is just sitting there depreciating , you're not driving it and you're not tinkering with it so just sell it already ,put the money in the bank and wait for something to grab you -

Mines all milk I'm afraid also I can't have fruit it's too acidic and I end up with a mouth full of ulcers basically my immune system just overreacts to pretty much everything it seems which is an issue because I have a really strong immune system so when most people get a cold they cough and sneeze and feel miserable for a few days or so, when I get it it puts me on my back quite literally then I'm fine the next day not sure if that's good or bad really but it is what it is. For the record I'm not looking for sympathy here I much prefers Superstu's response of "Man up soft lad." just curious to see if anyone else has similar issues and you know what they say "Misery loves company" .

-

just showed my missus this post she Pi**ed her self laughing

-

on the bright side my enforced diet is ridiculously healthy

-

So my missus was calling me a freak again earlier due to my many food issues, she's mean like that so I was wondering how odd I am admittedly I only know one person with any food issues and and that's an allergy to shellfish so here goes with my little list I have Coeliacs so no Gluten so bread or anything with wheat in it which is pretty much all processed food I'm allergic to some shellfish,oily fish and some cheese and I'm intolerant to All dairy - milk or eggs (any source) or obviously anything made with them beef,lamb,coriander,cumin, almonds and yeast also I'm not allowed alcohol I'm thinking it would be good right now if someone could come back and say that's nothing I'm allergic to water and air

-

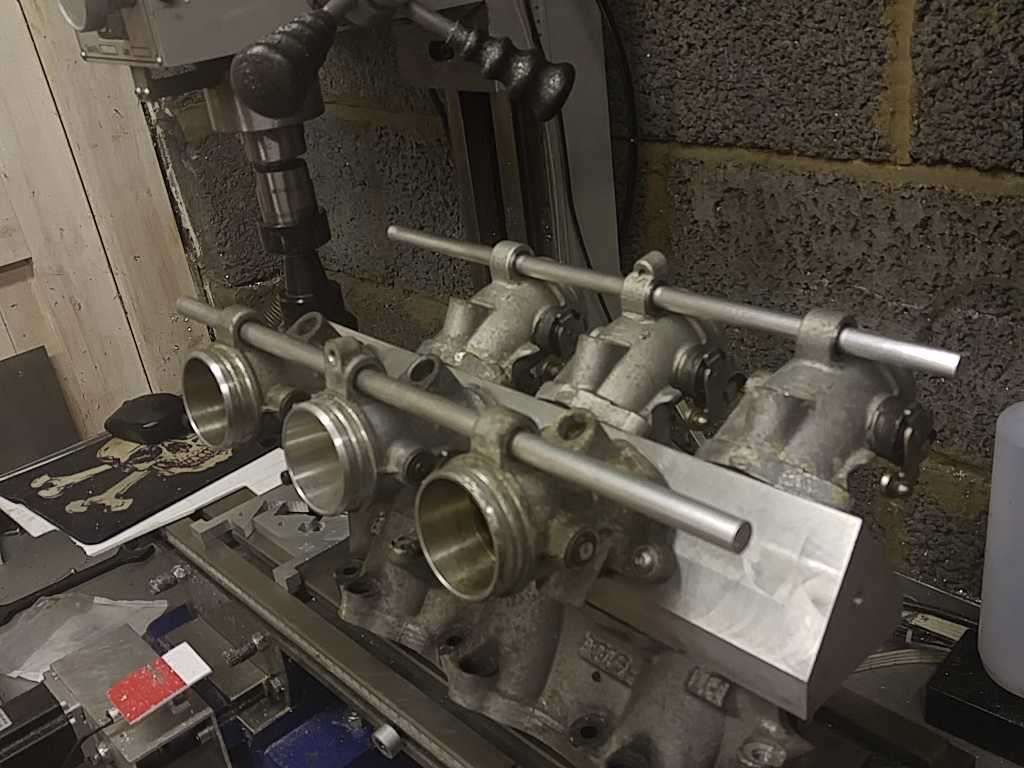

So current state of play, have now machined the 37 Deg angle on both sides ready to machine the elliptical ports and mounting holes for the BMW V10 throttle bodies I really have to get this right first time there's no way I can face doing all that work again.

-

Oh I thought that was a trial one and you were going to throw it away and do it properly Only joking Mr K, I wouldn't know where to start with a manual machine and I still think you should convert yours to CNC it would be bloody awesome

-

Now your machine converted to CNC that would be good

-

The real limitation on mine is the stepper motors are too small I ended up using the ones off the previous machine I built ' the problem is if I change them I also need to change the drivers and adapters I made which will probably cost me about £250 -300 per axis and a big chunk of time, so the best part of £1000 and to be honest it's not the money it's the time I've got other things I want to do.

-

Ok I'm going to go for looking dumb what's half cnc ?

-

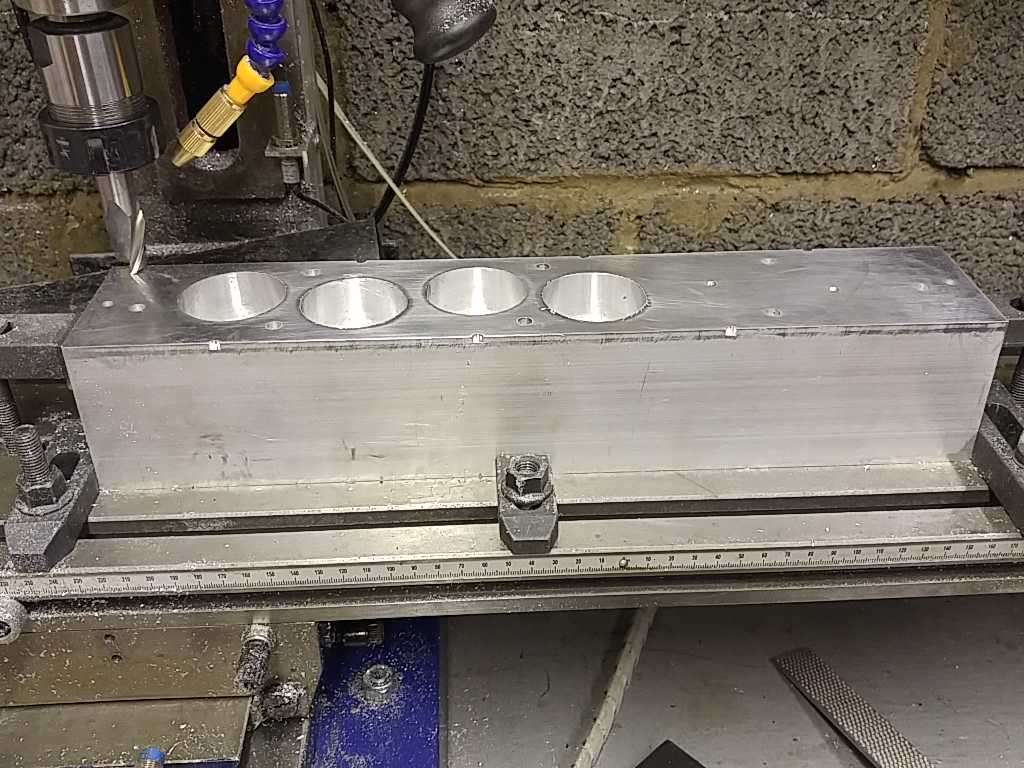

I'm making progress today but it's very slow going due to the limitations of my milling machine but I'll just have to be patient

-

I'm on schedule so far and no F*!* ups and I'm hoping to get quite a bit done this weekend unless the missus has plans for my time

-

Each port is taking about 3 hrs to cut so I've been starting one off when I get home and it's finished just in time for dinner, 2 more on the bottom then machine an angle on both sides and 3 more ports on each side so at this rate it will be finished next weekend as long as I don't mess it up, if I do then I may give up I'm not sure even I have the patience to start again

-

If you drag photo's in but don't use them it shows them anyway and won't let you delete them ....Bloody annoying

-

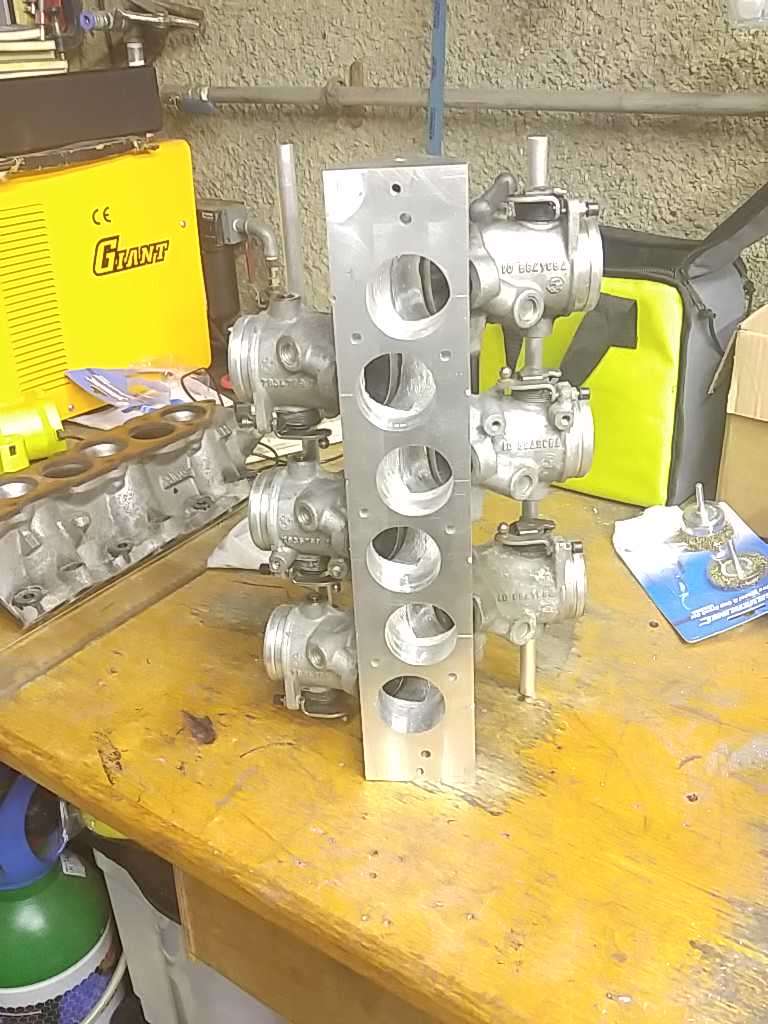

Even though I've had a bad case of man flu this build has been progressing though most of the work has been done sat in front of my computer trying to cut 3d ports on a 3 Axis milling machine is hard work I've also been cutting some test holes before the main event as the large chunk of ally I will be machining isn't cheap This is the test piece And this is the actual one I will be using so far the time taken to machine this piece is about 4 hours I estimate about another 25 -30 hrs to finish

-

a wise move I think

-

That's what it feels like ,if you're looking for a cheap route to power you can't go wrong, if you want the ultimate in throttle response and a sexy as hell induction roar go fit individual throttle bodies it's brilliant but not cheap

-

rear mounts don't feel so much laggy it's more like you lose the throttle response it's a strange thing and it's why i went the other way after I did my rear mount and went over to individual throttle bodies instead so I've gone from one extreme to the other

-

they tend to be a little easier on the engine due to the lower charge temperature also less heat load on the oil due to the cooler turbo

-

yep pretty much spot on