-

Posts

3,376 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Everything posted by evilscorp

-

Wasted thread, think ive decided how to do it. lol. Going to file/cut/grind (whatever is less invasive) one sides, 8 tabs off then use the press to push a die through the other side. Hopefully the cup should pop off at the filed side if not, I will then dremal grind the 8 better exposed tabs on the pushed side and then have to rigg something up to push the cross part the opposite way so it has enough space to be removed.

-

I assume from some googling they are staked/peened in and the wee tabs may bend out when pressed. Yes its getto again... but I think there is enough metal to peen them back in place once it all goes together again. (square punch or chisel on the middle of the alreaded marked 8 points.)

-

I can think of only one person on the forum who may answer this but worth a shot. How do you remove the propshaft U joints? The appear to have a pressed in spring clip rather than a circlip holding the U joint cap/bearings in-place. Going to (don't judge or hate) getto shorten the propshaft for the 200sx s14a but I intend to cut 1.5" of the carbon fiber tube off and use a press mounted sideways on the ground with a sling attached tp the press to hold the bottom of the propshaft and press the (believe it to be) serrated coupler 1.5" futher down the tube until I remove the 15cm length needed and use a resin on the last push to help lock the serrated coupler inplace and strengthen any of the cutting of fibers as its been push inside.

-

Yeah, my dad was the same. The pension map is in a total shift at the moment.

-

Thought I had a cast iron pension with my current employer of 7 years, nice final salary pension I pay 21.5% of my wage into so I could retire at a 60+ age rather than 70+ I expect it to become (i am 35), Sadly this year its all been shattered, must have been made from British steel (previous employer and that pension went belly up, but has floated to the surface hopefully without going into PPF). So Now I am looking at a new pension with my employer who I couldn't trust for @*&% with my money. Do I take the £4K cash in hand softner and invest/spunk however I want or trust them with £8K ( incentive to put money into the pension without tax hit.) For me its premium bonds and fingers crossed. Most of the younger folk I work with just don't realise how much money they will need when they retire to be comfortable. Happy to pay minimum into pensions. As stated its tax efficient to pay more into them, but as long as I keep it under the tax threshold at the other side, I will be happy + no major outgoings. Sadly I get envious of my parents who have pensions close to their incomes after tax when they were employed. Plan for the worst, hope for the best. Big money, big money, 1 mil PB. lol. Odds also look surprisingly good once you have decent money in.

-

Going to getto my driveshaft, probably not wise but ive seen photos of the couplers and videos of the push fit ones being made. Need to cut 15cm off and then make a jig to press the metal serrated coupler back in with some epoxy resin. Going to do it at the gearbox side so if it does break it doesn't puncture the fuel tank. Yes its dangerous, but I might try to sneak it into work and use their balance rig to spin it up and check runout if not I will have to make something.

-

Nevermind answered my own question, managed to adjust the clutch pedel to allow free rotation of the gearbox output shaft when in 4th gear and pedel pressed then unable to turn when the clutch pedel is up. The conversion pedel had come off a high milage car so was completely backed off and the stopper nearly all the way down.

-

-

Looked in the trash and found the old slave off the tranny, It doesn't appear to be different from my new slave and there is no extended/spacer/guide at the front. I can only assume it was either fitted incorrectly by someone previously or one of the years nissan was doing improvements;- cast thick clutch fork, small pivot ball but less sturdy/long guide for slave cylinder. Need to wait for a new fitting as I nearly wrecked my master cylinder by using a M10x1.25 thread when its a M10x1.0 for the s14a. Fortunately I had not done it up tight and the threads aren't cross threaded, just noticed the leak after I put some cardboard under it overnight. Guess I will just test the clutch and hope it works otherwise its £50 for a new slave which I really need to stop spending money on this project and get it driving.

-

Think I may have ran into an issue with my koukicuda build, I’ve fitted a transmission which I believe maybe from a later spec car and I am sure I used the smaller pivot ball but I am sure my slave cylinder is my spare from my 350z which is an 03. From looking on here Adrian had posted a side by side picture of earlier 03-04 slave and a later 05- slave which seems to have a spacer at the front which will allow the piston to move further outward in comparison to the main body of the unit. basically I need to find the measurement from the centre of the slave mounting bolt (smallest distance one) to the tip of the piston (or where it touches the fork arm) when the clutch isn’t depressed. I would just buy a 05 slave but I’ve stupidly just made my custom stainless Teflon line and filled it with fluid. not sure if I will pop the piston out if I press the clutch down, or bend the rod due to being too long a travel.

-

Nice to have a wee freshin up every now and again, like the new look.

-

our cars dont use a return line, so pump forces fuel into the line and it stays at the desired pressure, when you start wanting more fuel the pump has to pump harder and regulate itself for the increased demand. A fuel return system keeps the pump at the same pressure and bleeds back any over pressure so when the fuel injectors start demanding more then the fuel pressure regulator simply stops diverting back to the tank on the return line to keep the pressure stable rather than force the pump to start regulating its output more... giving the increased chance of issues. As above its not needed just there to increase safety margins and less stress on the pump.

-

Not 100% up to speed on 370z things but can you check to see what AIT (air intake temps) see if you can lower them with larger piping and bigger intercooler? What crank pulley does it have? I know with my 350z vortech setup increasing the size of the crank pulley slightly with a GOOD dampened one like fluidamper or ATI? will spin the blower faster without increasing belt slip much, Even smaller pulley but more ribs (new pulleys throught needed). Larger supercharger would be probably easiest Rotrex I think is the brand of charger the kit uses, so go next size up and obviously check clearances for fit.

-

The one in the second last picture, it connects to the intake pipework. The dump valve largest pipe on the intake had been blanked off.

-

Hopefully either yourself or docwra can help but ive forgotten what the blue hose on the far right bellow the throttle body is for? Is it idle control valve? Is it needed? The aftermarket hose it too small dia internal to fit onto the intake pipework so would need bored out and its also going to be in closer than prefered proximity to the fan as the shroud needed cut. Still need to make some foam surround for the fan cowling as its got a large gap (propably the old ac rad took up the space?) also have to try seal up the holes I had to cut so it creates the best suction possible. The bottom rad mount I grinded away a small spike for it to sit in, hope to stick a rubber washer over it to reduce movement at the bottom and I still need to drill the holes at the top to hang the bolts from. Got some money back as the intercooler arrived slightly damaged as it was poorly packaged (end pipes were bent slightly), also I think the hose couplers I was sent are ill fitting but I fortunetly have plenty spare in my stash.

-

JDM garage, think it was a black friday purchace with the koyo radiator and a r35/350z maf pig tail. The plan was to keep the original sr20det maf which doesn't normally do well without a recirc valve and also plumb in the 350z maf and housing I have spare just down from the throttle body as it copes fine with a blow through style but I got fed up so I will either have to swap them over when tuning (whichever is easiest for my tuner) also need the oem one to create a base tune with the power fc. (might be an option to use 350z maf on it not sure)

-

Done some wiring for gauges but need to take photos, also got fed up trying to make my old 350z vortech intercooler work with a mixture of custom pipe/couplers so have ordered a crapspeed high mount as the normal ones wont fit with the boss kit and I prefer the shorter pipework. Also got a new baffled oil pan as the old one is rusty and leaking.

-

Just my luck, the gktech shifter was too tight and wouldnt spring back up, emailed them and was sent a new nylon part but ended up shaving down the one I had, it may need swapped as reverse can still stick the gear lever down, hopefully a bit of wear will free it up.

-

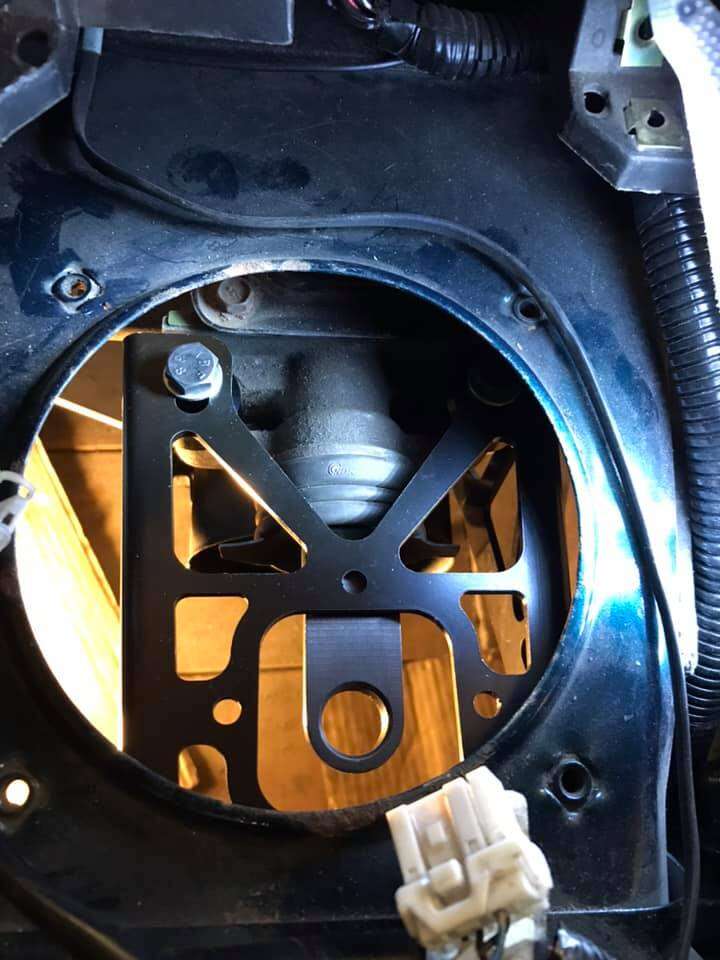

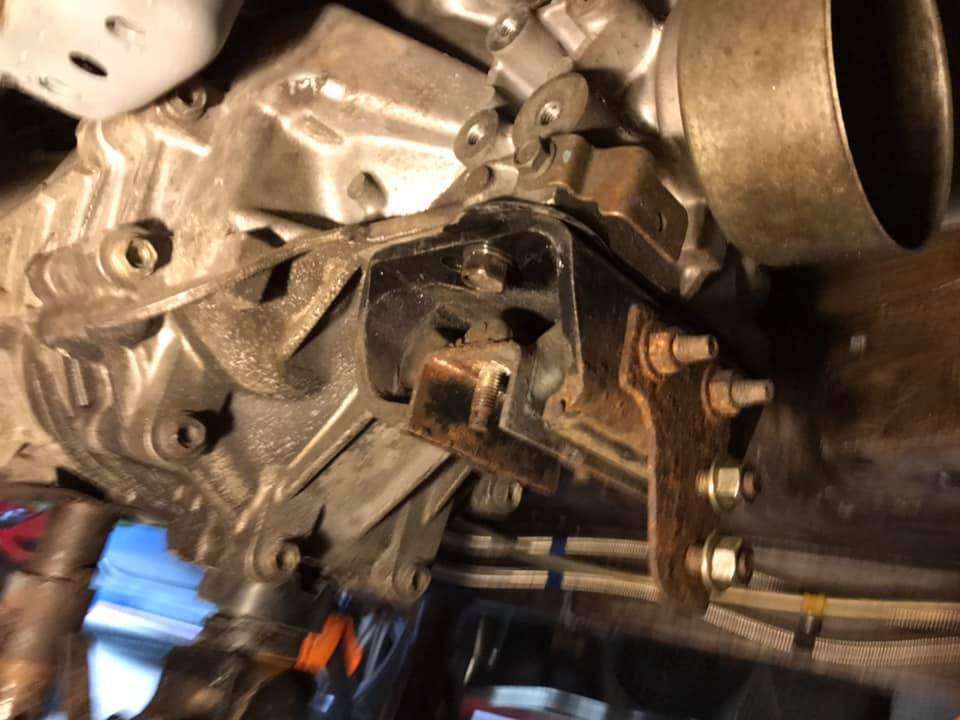

gearbox mount needed moving forward as the protuner bracket was too short to reach the front bolt holes... nice of them to say. Had to shave a bit off the gearbox reinforcement fins/casting and drill new holes in the 200sx bush mount (may buy a new hardrace one if this is too soft) also used some rubber membrane as packing/dampener.

-

The project is still alive, just need to update this thread, busy working 12 hour shifts so not easy to find the time to work on the car for long periods. Just sorting out small things like wiring gauges etc, only bits i need to buy are a custom downpipe, propshaft, tyres and windscreen. Then its all down to me. Had to wait ages for a replacement part on the gktech shifter as the nylon housing was too tight and couldnt select reverse without it getting stuck down.

-

Started and stalled.. need to get some free time to finish it. Welcome to the forum RenCli

-

Front end suspension overhaul as the whiteline drop links came up as and advisory last mot and I knew the bushes were shot on everything as all the arms were OEM 2003 parts. Also did an oil change on supercharger and main oil 5w-40 castrol edge. Front brace is rot so swapping that out too. Had to cut off upper camber arm nut as it wouldnt budge and I cheaped out and only bought tie rod ends and the jam nuts are welded on with rust so having to wait for new inners. GKtech new designed upper camber arms will be easy to adjust on the car due to the design, just footery to hold the 8spacers (castor adjustment) while trying to bang the arm in place (one side was very tight to get into location). But if it allows me to adjust (or get someone with a hunter alignment system if I can't be bothered) without having to take the wheel off each time then brilliant.

-

No, if you could that would be great. Been busy doing the front suspension on the 350z not got round to the rear yet to get a good look at the plugs.

-

Night and day difference, if I had the money and time I would have forged the pistons by now lol. So easy to work on but the spaghetti of coolant hoses is a joke. I originally just wanted to keep it all oem and just slightly raise the boost, then I thought if I want to eventually build a TT VQ then I may as well get a good turbo. The oem manifold wont crack and had hoped the exhaust and intake pipework would all work with off the shelf stuff.... I was wrong and wish I had gone V band and top mount for easier custom piping. Also wanted it to look oem and hide the big turbo under standard heat shield (still will) but then figured I may use the 350z maf too save headroom hassle and fit it just before throttle body, not sure why more people don't as it will be better if I dont use a blow off valve..

-

Sorry for the double posting of some photo's, loose track of what I have done sometimes. Jump from one thing to another too often. New air hammer/chisel arrived so going to work on the 350z for a bit lol, dam ball joint clevis pins.