-

Posts

1,355 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by andybp

-

-

8 hours ago, davey_83 said:

Leave it stock

too late

I already have a new exhaust and W brace on the way from Tarmac Sports

and as I will tell my wife "Honest my love it was a gift"

-

2 hours ago, andy james said:

Well done Andy. Have you got a name for it yet! Lol

Hopefully not Christine like the 350z

-

1

1

-

-

1 hour ago, davey_83 said:

Leave it stock

Too late

-

The wife says it can't come in the house and has to sleep outside

-

3

3

-

-

So as I explained to my wife I just went out for a drive minding my own business and this little black number followed me home

So I had to adopt it as it had nowhere else to go

-

5

5

-

5

5

-

-

Keyser has anyone told you that you're "special" really really "special"

But I hope there is no cure for it cause it's awesome

-

3

3

-

-

So even though I intend to sell my Z this year while all of these restrictions are in place I have been doing all of the little jobs I should have done ages ago

including refining and simplifying the the air ride control I had some power supply issues when the compressor was running and fitted an extra battery next

to the control unit which solved this but have discovered that a couple of large capacitors work just as well

it used to have a pot to adjust the ride height but i didn't like it so went over to a rocker switch also since I plan on selling I've relocated and refitted the factory amp which I removed because it was in the way of the tank I also plan to fit a led bar graph display to indicate height as I never found an appropriate location for the touchscreen display I've also rewritten the software to improve the height / pressure averaging to stop it making continuous adjustments I'll get some pictures up some time this week

also I get a lot of people contacting me asking for help and information about some of my diy projects via PM instead of replying to posts usually they have no posts and no profile info in the past I have helped but it takes up my time so from here on if you're not contributing to this site then I can't spare you the time

-

4

4

-

-

On 28/04/2020 at 08:55, Keyser said:

Hello again, I’m still at it but as promised I’m gonna mix it up with a side project, which you may or may not find interesting

Long Pic Heavy Post follows -

I decided to have a play with the milling machine

I got a fly cutter with the first milling machine that I have never used but to use it I needed an oil feed and cooler, as I don’t have a catch tray on my mill I cant use the recirculating pump. To solve this I ordered an atomiser from China (because silly cheap) last year it took 3 months to get here and has been sat in the draw ever since.

So I got me brand new BLACK! eBay trainers, purchased just for the Shed – with Velcro so I can take them off easily to go in the house (I keep bringing metal bits in

)

)

Lovely shade of BLACK are they not?

I started by getting out my box of airline connectors and found a load of bits

Drilled a hole in a bottle top and fitted the oil pick up line

Found this old clamp

Cleaned it up

and welded this plate to it

So I had something to hold the atomiser steady

That goes like this

Side Note – Angle grinders are strange – blow up 1 get 2 back

Made up an air feed with regulator

I use plastic airline, but don’t have any, it just so happens the connectors work on 15mm copper and I did have some of that –

That gives me all the connections I need

Next to the Mill itself

Needs a clean …. Ta Da

Now to test the fly cutter on a bit of old steel

That I cut off the mobile welding table I made…. This one

Using this

If that’s not a recommendation for these saw’s I don’t know what is

To the Mill – first side

Some time later

Wow – I like it

A hole is needed

Then some more old box section

Back to the mill and some more time later

Now weld a support bracket onto the first bar

And the box to the bracket

I love welding heavy metal

Warning – the following contains the destruction of 350z parts – viewer discretion is advised

Old exhaust end

If you cut the back off

You can take out the inner bit

To leave

More old box

Yes even more time later

Weld that all together

Then change the design

And hide the evidence

Add some straps

Add the stainless exhaust – first time welding stainless to mild steel and something that thin to something that thick but it Tig’d up OK

Off cut of worksurface from Mrs K’s kitchen refurb

And we have ………………………

Now I can keep my tools to hand at the Mill

And the oil won’t get knocked over

Over engineered? Probably but it was good practice and I now know that my Fly Cutter works

Be safe all.

Keyser - “Better to remain silent and be thought a fool than to speak out and remove all doubt.” – Abraham Lincoln (maybe I should have listened to Abe? )

engineered to the standard your renowned for i would say

I'm on my second one of these they seem to block up/gum up easily as you say cheap but good for the money i have a dosing pump feeding coolant (water and a splash of antifreeze) to mine I either use just coolant, a mist or just lots of air depending on what I'm cutting

-

2

2

-

-

Just caught up with this good work love the bead roller quite envious to be honest

I thought you also had a Tig welder i find it good for different thicknesses of metal

-

1

1

-

-

Definitely going to have to upgrade the engine that things gonna weigh a ton

-

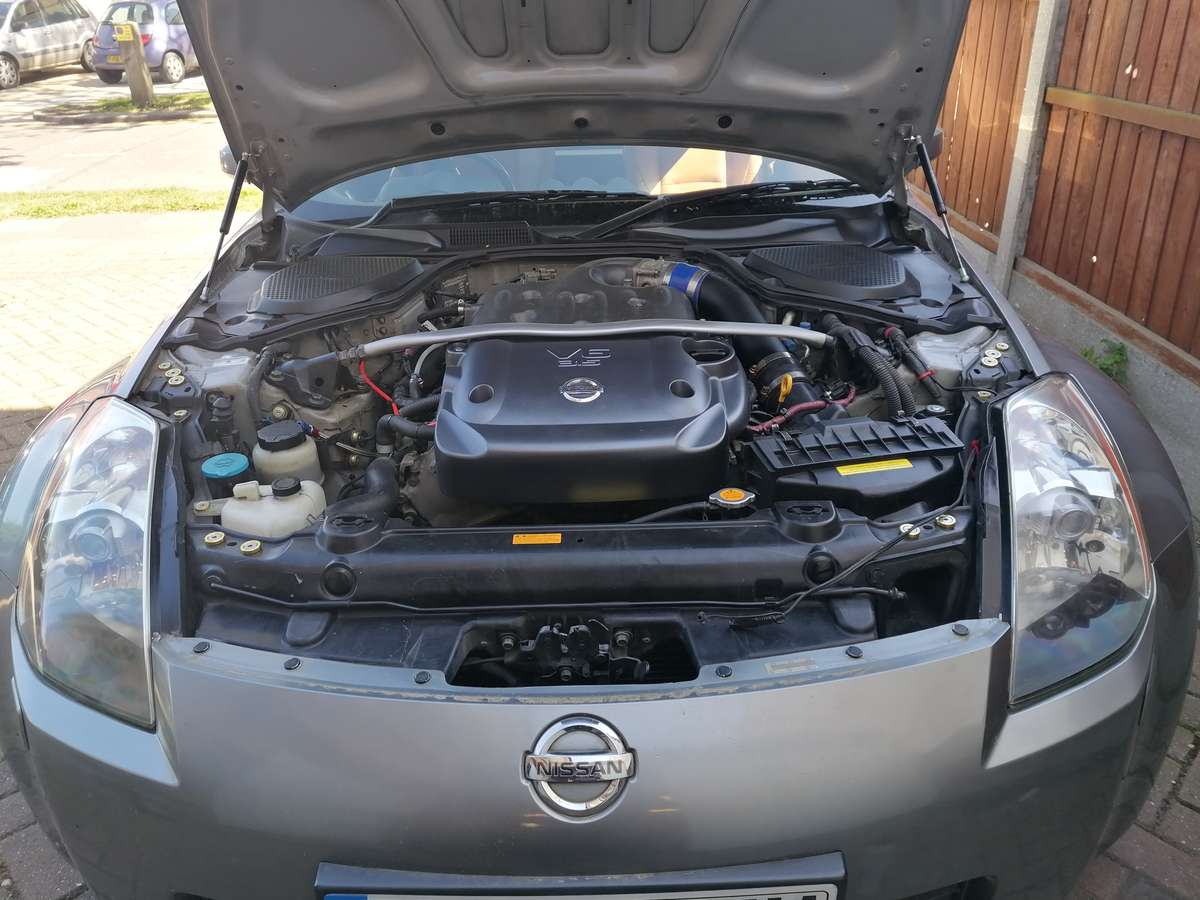

So the age old problem what's it worth

This is how it will be sold

spec wise

18" alloys good tyres all round

BC Racing Coilovers with custom Air Ride setup

some of the suspension is poly bushed I have them all just haven't fitted them

true dual exhaust HKS copy

standard cat's fitted but also have high flow set that would go with it

high capacity ally sump

Link G4+ plugin ECU

also another engine with 25000 miles was fitted at 68000 miles now at 76000 miles so engine has about 33000 miles on it

Please note this is not an advert just trying to get an idea what I should put it up for when all this corona madness is over

-

good work as always Chris, did you make the last picture blurry just for me

-

9 hours ago, Keyser said:

Only a hint????? You sir have the skin of a Rhino

At least I'm good at something

I call it thinking outside the box section - see what I did there did ya? did ya? O come on that was good

I agree with this and I'm sure I could do my bit - Not so sure you are up to yours though!!

I know 3 people from Scrapheap Challenge, if you used to watch it I know Bowser and his wife who were on it for a while and Dick Strawbridge who went on to make his own series was a Major in the Royal Signals and my old OC - small world

From what I understand from your comments I am an ugly useless rhino some people are sensitive with feelings you know

luckily that's not me, someone as sarcastic as myself has no right

-

1

1

-

1

1

-

-

9 hours ago, Keyser said:

So many comments - Thanks for taking the time and I'm glad some of you are enjoying the thread, I know I read loads of build threads online.

@hicksi- you know some random stuff mate This would make ours a Mk2 then, water cooled, belt drive and the final drive after going through the "reverse" assembly is drive shaft, it’s still a very basic engine and still uses the Chinese monkey metal for most of it

No idea where @Beb and I will go next we may just upgrade ours with a bigger engine, nothing set in stone just yet.

Don’t call it isolation please, it makes it sound like solitary confinement or something

I’m far from that, yes I’m working from home (I did anyway) although I had a call out yesterday for a server fail, but I have keys so I just let myself in sorted the problem and left

I’m far from that, yes I’m working from home (I did anyway) although I had a call out yesterday for a server fail, but I have keys so I just let myself in sorted the problem and left

I’m also home with the lovely Mrs K who is also working from home, my 2 daughters, one is on long term sick with a rotator cuff injury and the other is still having to go to work as she can’t work from home, most of the staff from the factory have been furloughed but she is the accountant and all the paper work still needs doing, but she is pretty much on her own so not high risk.

Keep the comments coming, I’m off to write the next instalment

Keyser

Don't talk to me about rotator cuff injury's been struggling with mine for 9 Months all the physio was just starting to work when Covid 19 comes along

-

Chris I detect a small amount of sarcasm in some of your comments please note that this is my area of expertise (just ask the poor souls i work with)

so please cease and desist

just stick with what you are good at eating donuts and taking blurry pictures

Excellent work by the way do love some of the solutions you come up with

we should have done scrapheap challenge you could have done all the work and I could look good for the camera

-

18 hours ago, SuperStu said:

The size and flexibility of your equipment is very impressive, very jealous.

Is it just me or is that a double entendre

-

3

3

-

-

-

only just a yes

had mine 8 years been lots of fun but it's going this year

-

13 minutes ago, Keyser said:

yes I'll give you that truly awesome bit of kit

selling because I don't have the time or the room to play with it so i'm selling to get a more practical car (z4 35i dct) until we move and I retire 6 yrs then I'll have the time and space for a toy again

-

1

1

-

-

Great work Chris

I always love to see this level of fabrication

sadly the only thing I've been doing is undoing all of my hard work and putting my Z back to stock (ish) prior to selling it

-

1

1

-

-

6 hours ago, Keyser said:

0.022mm

just some of us have higher tolerances than others

some of us have a clunky agricultural mill others have a higher precision CNC machine

some of us are more equal than others

sorry Chris couldn't resist

-

1

1

-

-

Nice looking car

I look forward to you getting your hands dirty

-

1

1

-

-

I would normally Critique your work but having lost my dad not so long ago I can empathize with you and your reasoning for the effort others would consider not worth while

Nice job Chris

-

1

1

-

-

7 hours ago, cs2000 said:

Haha that's a shame, I would be interested if you found the time of course! Wouldn't need your coilovers however as I have the BC BR's already, just the lines and everything else that goes with it.

I'll see how the virus goes as i can't sell the Z until it's over so what else am i going to do ?

-

1

1

-

Not sure how this happened

in 370z General

Posted · Edited by andybp

incorrect mileage

In case anyone was wondering what happened to my 350Z the answer is nothing I still have it

it will be sold but I still have some poly bushed suspension arms and a clutch slave cylinder and hose that I never got around to fitting and I might get the wheels refurbished not sure about that yet and a few other little jobs so at present it's at work where I have more space

18" alloys good tyres all round

BC Racing Coilovers with custom Air Ride setup

some of the suspension is poly bushed I have them all just haven't fitted them

true dual exhaust HKS copy

standard cat's fitted but also have high flow set that would go with it

high capacity ally sump

Link G4+ plugin ECU

also another engine was fitted at 68000 miles with 37000 miles on it car is now at 76000 miles so engine has about 45000 miles on it

She'll be going up for sale within the month I'm in no hurry to part with her but if anyone locally is interested you can come take a look