Cosmic73

Members-

Posts

175 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Everything posted by Cosmic73

-

Hey Glen, what a great post, your Z is punching well above it's weight. My gearbox crunches in 5th so I'm going to replace it's synchro ring when I get the time. Did you fix your gearbox yourself or send it to a specialist?

- 256 replies

-

- waxandshine

- hillclimb

-

(and 2 more)

Tagged with:

-

Good luck with the build mate. Your wheel story reminded me when I took my old MR2 to a garage in Coventry for a new a tyre. The bloke didn't hand start any tyre bolts and just gunned them in with an impact driver. Instantly crossed the bolt which seized but he just carried on trying to gun it till I came steaming over, then the Muppet blamed me for them being crossed.

-

Sorry to hear about your Z mate but thanks for organising this, credit where it's due 🙂

-

Cheers Dave. Those pics are even better! Thanks for sharing

-

Thought I'd share some pics and vids of the mighty Z popping it's cherry around the Silverstone track this afternoon. https://photos.app.goo.gl/MntHxeNMqqUJUW3G7

-

Hey Dave, it was great to meet you and other members today. We had a great, thanks for arranging 🙂

-

Yep, you heard that right. The exhaust i have is too loud and i know it's going to hurt my head when i drive for more then 30minutes. Does anyone have a stock exhaust they want to sell?

-

I suppose he did the obvious and checked the linkage was ok? If that's ok, it sounds like it might be an internal gearbox issue.

-

Just wondering why an MOT test would require driving the car fast enough for 6th

-

Just passed it's MOT. This Z is the gift that just keeps on giving 🙂

-

Haha, yeah it sounds a bit strange when you put it like that, but I'll be taking it fairly easy round the track. It's all about the experience and having fun, but next year I'll be hammering it.

-

I saw that thanks Dave, but I think it might be a little too soon for the mighty Z but I'm definitely up for Japfest tho.

-

Well that's it all done really. Fitted the new valve cover gasket and put back the air collector etc back on, no leak! Ran it up to temp a few times and bled it a few times and nice hot air now coming out the air vents. The only thing to do now is change the mineral running in oil with new synthetic. Next week I'll be putting as many miles on it as I can ready for the track day.

-

Cheers Dave, I was about to buy a couple of second hand ones on eBay. Idea of the hire cost, roughly?

-

Nice looking Z, good luck with the sale

-

Oil leak solved, yes Dave, you were right, part of the gasket had slid out while fitting and was actually being sliced by the cam lobe!

-

-

I can't remove the plastic hose running between the valve covers and scared in case I snap them. Previously I removed both valve covers together so it wasn't a problem, but now I just want to remove one, I'm stuffed. Is there a tool or special method?

-

Looking good, top job. When do you think you'll have it done by?

-

That's exactly where mine's leaking and trickling down that bracket. I'll see how it goes tomorrow, but looks like I might have to refit it. At least it's not the head gasket, that would be a show stopper. 🙂

-

Cheers pal, the warm up went fine thanks. Reached it's temp, I kept the revs between 2-3000rpm to bed in the rings. But, there's an oil leak! It seems to be coming from the back corner of the rocker cover near the throttle valve. It's dripping oil on the exhaust manifold and smoking like hell. I've nipped up the rocker bolts and will run it again tomorrow and hope that fixes the leak. If it doesn't I don't know what I can do. 😞

-

It lives, it lives!!

-

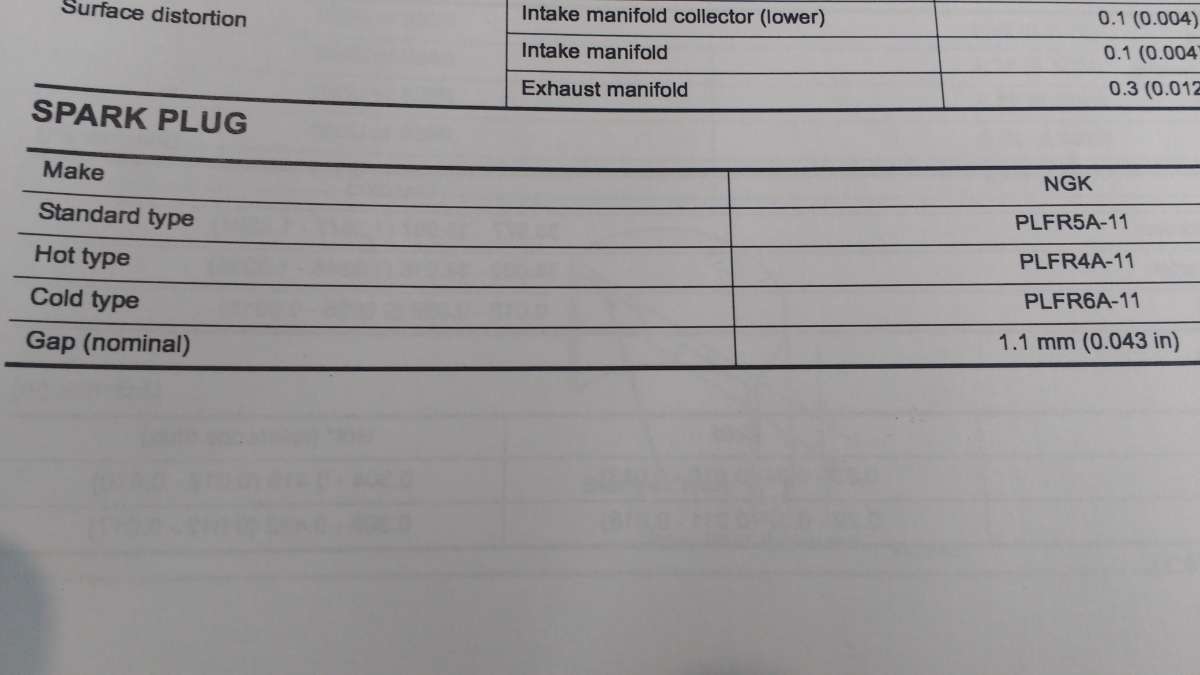

Bought new OEM plugs and according to the manual the gap should be 0.043" Thought I'd measure them and the gaps are actually 0.028" (0.711mm) which is miles out. WTF is going on, I thought these were pre gapped or am I having one of my senior moments?

-

Just PM you Alex

-

I think I found them, but they're in the US. https://conceptzperformance.com/nissan-infiniti-nissan-oem-intake-camshaft-vtc-seal-vq35de-revup-vq35hr-vq37vhr-vr38dett-nissan-350z-370z-gt-r-infiniti-g35-g37-q40-q50-q60-fx35-fx37-m35-m37-qx50-qx70-13042-3hd0a_p_4665.php