-

Posts

303 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by Mike_89

-

-

I am finding it difficult to progress with my digital dashboard as I am back at University now, so hopefully will find a little time over the Christmas break to progress. I contacted Nissan regarding their Consult II Protocol. They didn't understand what I was after at customer services. I asked for the engineering team etc. All I need is a schedule of, some sort with, all registers and descriptions. If I was designing a control system the client would ask for a list of all registers that are available in the control system. So would have thought it would've been a simply task for Nissan to provide this information.

There is a more of a hit it with a hammer and understand method, which would be to use a Consult II applicable software and monitor the RS-232 port, and record what the software is requesting. Then it is just a trail and error to get the registers correct.

It's great when you get going, although I found with mine that I have big progress sometimes, but with large gaps of inactivity in-between. I'm itching to unstick my current hiatus - last 10% seems to be taking 90% of the time - but thats all due to scheduling conflicts rather than actual technical issues*

Have you pushed on with your Arduino Due yet? I have started dabling with mine, and have been coding the display, including getting a ton independant of sensors together..

*although ostrich sticks head in the sand and ignores potentially scary gearbox noises..

I would like to see how you manage to install the gauges within the door vents, I assume you will be routing the wiring through the existing door loom.

Good to see your cracking on with it mate, Im having many large gaps of inactivity with mine at the moment, I keep laying everything out on the floor in the living room and just staring at it

im putting one of my gauges in the door vent

im putting one of my gauges in the door vent -

Interesting write up pal, looking forward to this progressing. Can't wait until the Wales meet with all these s/c zeds.

Loud would be one word I would use to describe a run out with a charged zed

-

1

1

-

-

Some progress being made then Mike which is good.

I didn't mention it but I started my own build thread as my Zed is supercharged now so I thought I'd add all the pictures I've built up over the last year.

It's in the "members build" threads if you fancy a look, ...not got to the good bit yet but won't be long before I add those pictures.

I have been itching to get started for sometime now, need to sort out the v2 ti-trim yet, but that should be straight after Christmas. Then will be going along to abbeys to get it sorted.

Just a lot of work to do before all that happens........

I will have a look now

-

I have finally had a little time to start mocking up and installing some parts for the supercharged zed. Wooohooo...

I started with modifying and installing wiring required for the boost gauge and oil temperature gauges. The location of these will be in keeping with the sleeper look i.e. cubby hole mounted. I now need to measure up and have a gauge pod manufactured to complete the interior install. I haven't yet routed the oil temperature sensor wiring and vacuum hose, and still open to suggestions to where the best location of these to be routed within the cabin i.e. needs to finish being neat and tidy.

I have also received a cool little item...... OCC from Saikou Michi Co. which seems like a quality item. Its location is easy to mount, but it looks like I will have to make a little modification to the power steering hose which sits in the way of the drain valve of the catch can.

I need to order some new hose to allow routing from the PCV to the OCC and from the OCC to the intake manifold.....

I will be removing the bumper tomorrow to measure up and locate the massive intercooler and oil cooler.

This picture doesn't really do the intercooler any justice, but it is huge.

I will hopefully be carrying out the fuel system modification once I have a new fuel pump. I can imagine this is a bit of a nightmare to route all new return lines back to the tank. I have the CJM Stage 1 system. I believe that I should be ok to install this without a remap, as long as I set the regulator to the factory pressure.

I also think I need a few polished items under the bonnet as it looks horrible in the pictures, or maybe give it a clean.

Edit: and maybe some carbon goodies.

-

1

1

-

-

COWBOYS!

-

Welcome to the forum

-

Always use Shell VPower and would use this in any of my future cars

-

Love it haha

-

They changed a Skyline into a drift car

-

He had a witty remark in the one where they had a lambo.

Quote: "Finally have a bull in the China shop"

-

1

1

-

-

Looked a spitting imagine mate.....

-

Spotted your car in Tesco yesterday evening

-

I had the same type of conversation with a Merc driver the other day. Drives me mad...

He basically revs the nuts off his car as soon as he leaves work. I explained what I did which is drive steady until my engine is ran up to temperature, and he just laughed at me.

-

1

1

-

-

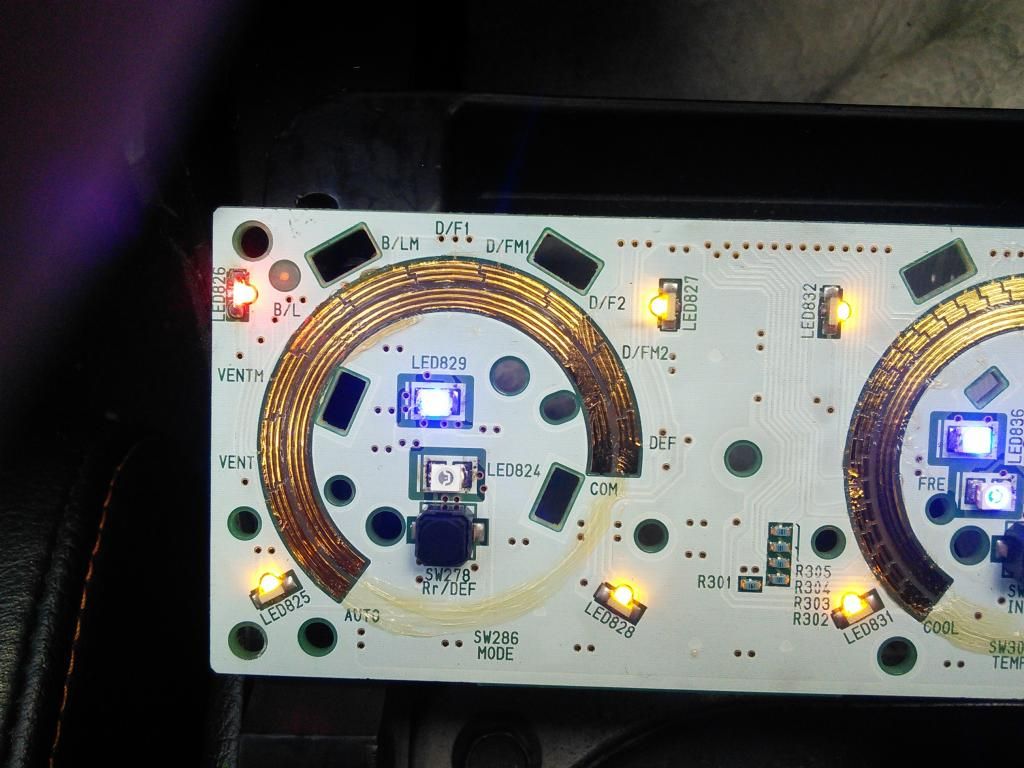

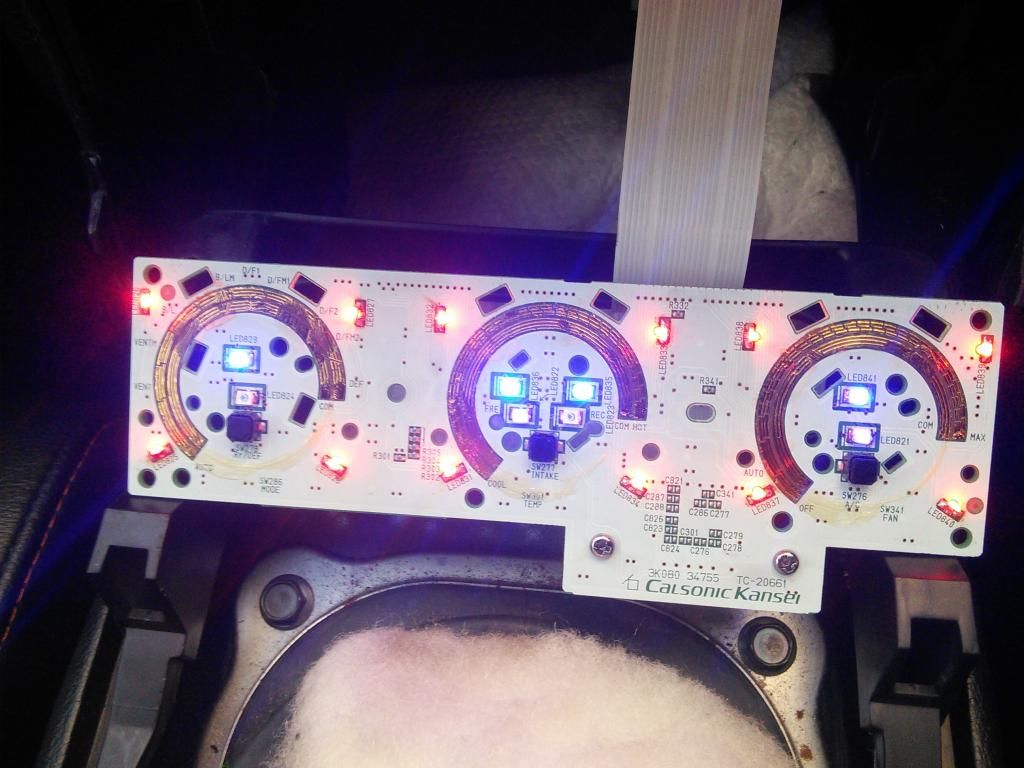

Doing this job you are removing LEDs for LEDs.

It isn't a difficult job to do if you have soldering skills. If you are not too confident with your soldering skills I would practice on the least significant controls such as switches and purchase a low power soldering iron (4 - 8W). This will be a little more forgiving when you are apply heat to remove the existing LEDs. I used a 40W iron which reduced the time to remove LEDs, but you have to be quick not to damage the contact pads on the PCB.

Problem..... Resetting gauge needles....... Take photos of all needles (Hot and Cold). Oil Pressure; Water Temperature; Fuel; Volt Meter

When I was ready to set the needles up I used an OBD2 Scan tool (purchased from Amazon for around £13-00 and download some different software http://www.outilsobdfacile.com/vehicle-list-compatible-obd2.php?brand=nissan), which allowed me to reset the water temperature once the car was up to temperature and to reset the rev counter.

Then to reset the speedo, you need to take it for a little drive (clear straight road). Set your cruise control to 20; 30; 40 < mph

I have a guide from a guy in the states which tells you how to do it, which I can email across if you PM me your email, this guide comes from Gauge Craft. Check out his work on You Tube https://www.youtube.com/user/MisterPatchbay.

I purchased the gauges from http://www.blackcatcustom.com/ (delivered in around 3-4weeks after order was placed, 21days for manufacture and 1wk for shipping). They cost around £60 - £80.00.

If you are not too far from Hull, I would be happy to lend a helping hand

.

.-

1

1

-

-

Very cool

Would be nice to make the large Z in the rev counter a different colour . . but I guess you can't

I will take this as a little challenge

.

. -

-

Use mine daily, if it gets a little damp its makes it a little more fun.

However most cars will suffer with ground clearance issues if it gets pretty bad with snow.

-

Seen as the doors are the same it may be possible to change the whole door cards, think I saw something like this in the states. I will try and find and post it up.

-

Welcome along. Nice looking Ferrari

-

1

1

-

-

I actually like all the videos that both Top Gear and Fifth gear have done

I tried searching for youtube for the Top Gear Iceland episode, but had no luck.

However I really don't like this one

-

1

1

-

-

Welcome along

-

Hopefully should have this complete by next weekend, if the gauges arrive from the states.

-

Just another little update regarding the LED conversion. I thought I would get cracking on changing the LEDs in the gauges this weekend, as I am still waiting to receive the new gauges faces (Hopefully I should receive them this week).

I changed the pointer LEDs in the HVAC Controls.

I then began converting the LEDs for the Centre Cluster Gauges.

Voltage Meter LEDs.

Oil Pressure Meter Pointer LED.

Oil Pressure Meter LED.

LCD LEDs.

Gauge Housing installed (Really need to get the new faces installed as the Blue LEDs do not show through these faces).

LCD screen installed

LED Conversion complete.

As you can see the blue doesn't show through these gauge faces. So I will post additional pictures up once I have installed the new faces

.

. -

Mine are headlight washer jets, esp off, and roof switch.

Proud GT4 owner says Hi :-)

in Introductions & Welcome Messages

Posted

Welcome along.