Ortega_9

Members-

Posts

449 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Everything posted by Ortega_9

-

-

I was actually thinking about dooing the IC when i paint the last boostpipe and brackets..... but the decided not to.... now i'm not so sure anymore

-

Thanks. It's a bit more discret... and then again... looking forward to putting the bumper back on and seeing how it all comes together....

-

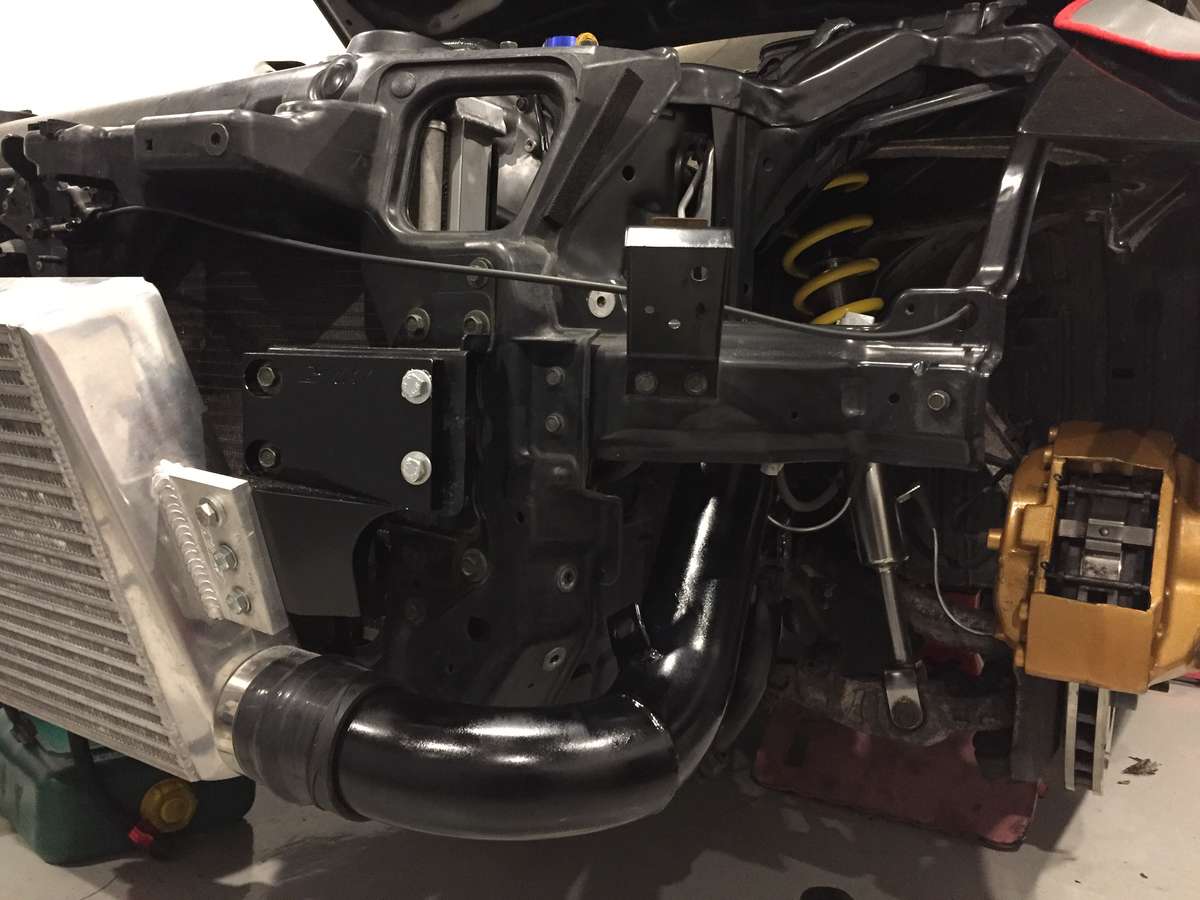

Friday Update.... getting that Nice "weld" ready for paint. and almost getting the last boost piping on.... This is starting to look very deathstar-ish...

-

Friday Update.... getting that Nice "weld" ready for paint. and almost getting the last boost piping on.... This is starting to look very deathstar-ish...

-

Some more boost pipe fitting. and also alot of small brackets and water pipes. This is a slow ass build, i know. But it's fun trying to come up with your own solutions. and everything is getting unnesesery attention, but worth it when it's done. i'we also done some horrible "welding", dooing aluminium with my mig welder.. with aluminium wire and argon. not the Best work, but it's possible, and this weld will be ground down and painted, so no harm done. dooing my engine breathing Lines in AN10 with all Black Lines and fittings.

-

Oil and water done. Except for the Oil return, which i cant do before the boost pipes are fitted. and fitted the engine Mount spacers to raise the engine 6mm to make clearence for the piping. so just started putting on some pipework. Carefully making sure that nothing rubs or hits anything.

-

-

Now it sits like it should. and just loosly fitted the intake piping to have a look at it. there is so many tight spots along the Way, due to the turbos beeing so large, that i can see that i need to redo alot of the brackets for AC Lines, wiring etc. but seeing some piping on gives me a boost of much needed inspiration to go on with it....

-

And turbo fitted... but still i need to remove more. i guess i didn't get the angle right when just fitting the turbo loosely with the two rear nuts only....

-

-

-

And seeing how much/little space i have to get this sucka in.... i need to shave down the engine mounts atleast 10mm and i need to make new/bend the old fuel lines.... And with that: gt3076, Meet tight hole..... tight hole... sorry.

-

I have just finnished fitting the right side manifold. it worked... and actually wasen't so bad. i had to hacksaw a few wrenches to get the two locknuts on, but otherwise no problem.

-

Having taken the manifold off and put it back on the "mockup" engine, i have found a solution... i Think.... if i put the most forward nut on first, and have the manifold at an angle, tilting out at the rear, i can fit a locknut in a small dent i grinded out of the flange, and this will stay in the indentation as i tighten it. i hope this works.

-

And trying to get the new manifold on presents some issues, i might need to machine a bit off the turbo flange in order to get room for the bolt. But this is the biggest and Highest flowing design possible for the manifold, so i knew there would be issues. otherwise it looks fine... so not all bad. But needs more work

-

the new bolt patern of the new manifold calls for all pinbolts to be moved. So cleaning a bit to get the best seal when the new manifolds go on.

-

In Denmark there doing fine.

-

Fitted. took 8mm off the brackets for the a/c cooler both top and bottom on the radiator, and cut new holes for the AC brackets. now everything sits like it should.

-

And almost in. i Can see that i have to trim the front member to get the radiator to sit like the stock one. i need about an inch more to get it to fit.

-

-

Test fitting the IC. making sure all pipes, Lines etc. Can go where they need to be before i cut any hoses to lenght....

-

Ok, i Think i solved the issue with having to much traffic in one place. I took the sensor/oil cooler sandwich plate and turned it 180* then the gauge sensors is on top. I Can reach and service the thermostat. And with a pair of 90* an10 fitting i Can reroute the Oil cooler Lines around everything and still have room for Oil pressure sensor, Oil feed for the turbos and Oil filter.... still alot going on. But i Would hate to also have an Remote Oil filter sandwich and Lines added to the mix, so this is the Best option i Think..... And it gets easier to change the filter becouse of not having the gauge sensors at the bottom...

-

Just done the Oil pan and spacer, and trying to fit everything Else... to much going on here, so i might have to get an Oil filter relocation sandwich to get the gauge sensors and filter away from this mess