-

Posts

1,355 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by andybp

-

-

1 hour ago, DoogyRev said:

I think I am the only one with a distance related excuse . . . but you can put me down again this year as a "maybe"

Hold on your profile says kent how are you further than me ?

-

1 hour ago, Mrs Buster said:

198 miles each way for us. We will be there with bells on!!

That's it make me look bad

-

1

1

-

-

2 minutes ago, Keyser said:

Sorry was the excuse - I live to far away???

Come on you can do better than that!!!!!!!

Oh sorry that's all I had

-

1

1

-

-

18 hours ago, Daisyduke said:

Could some cam cover heat shields be made up then just pipe air over them?

yea I did consider this among many other options for now I'm going to move as much out of the way as possible then I've got some really thin sheet ally I can bend by hand to mock up whatever solution seems best

basically I'm winging it

-

one day i'll get there, why do I have to live in crappy southend.

-

1

1

-

-

1 hour ago, GrahameJ said:

The standard plenum doesn't have that much clearance past the end of the air intake runners, so unless the trumpets are longer, something like that with less clearance to the trumpets should be possible.

Maybe starting with aluminium sheet as a backing plate attached between the throttle bodies and the trumpets, and then fabricate a box containing a circular inlet that will fasten to this.

Ideally you want to feed cool air in from a high air pressure area such as through the grille.

If they will fit a DE, I'd use two 350Z HR air-boxes and then connect these to the boxes surrounding the trumpets.

The HR air-boxes could then be fed by something like the EVO-R cold air intake. See my efforts on my DE:

http://s12.photobucket.com/user/GrahameJ/media/IMG_2404_zpsvx8xzzzi.jpg.html

Don't get me wrong I agree it's do-able but I'm not going to enclose it as I find it aesthetically pleasing for now I'm just going to continue to optimise space around the trumpets and then decide

-

1

1

-

-

17 minutes ago, Bakkums said:

It would that's a vq35 but that's not a 350z bay it's in and I just don't have the clearance even after moving the vacuum manifold but I'm getting there.

-

3 hours ago, Keyser said:

signed up in anticipation

no pressure then

-

1

1

-

-

7 hours ago, Flashback said:

Haha it's curtains for you! I wonder then maybe if there's a non engine powered way you could circulate a fluid. Could something be propelled simply by air flow that could in turn move a pump?

Trouble is it's only really a problem in traffic or when i'm not moving when there is no airflow, when i'm moving it's not too bad

-

27 minutes ago, Flashback said:

I know this is a bit of an off the wall idea Andy, but could you run a kind of fridge in the engine bay by making some adiabatic pipe work and then run off the heat else where away from the engine bay?

I think that to extract the heat as opposed to just releasing it ie by venting the bonnet will use a lot of power if there was a simple way of getting rid of the heat then our aircon wouldn't use such a large amount of engine power but I like your thinking though

as it happens I've been re-arranging things in the engine bay to try and allow room to duct cold air to the inlet in fact I was making progress until the missus got me putting up curtains

-

So here I am again with more DIY madness

I live in Southend On Sea the roads are crap and there are speed humps everywhere including down my road shortly and I'm fed up with having to plan my route around town based on speed humps I can't get over

but as some of you may know I'm partial to a project and some would also say tight. actually I'm not tight I just do a really crap job for a living (literally) so demand value for money when I part with it

This is not going to be a shiny setup for show hopefully it will all be hidden and OEM looking and much of it will be, just not Nissan mostly Audi with range rover height sensors, aftermarket Bags and a custom built controller

just got to wait for stuff to arrive now

-

5

5

-

-

Damn I hate bodywork

-

Maybe I need to stop ignoring mine

-

The 2 colours that are the same both black or both white usually should be the heater which is easy to check not sure what it should read though at a guess I'd say 3-5 ohms

-

definitely sounds like the bov not opening so if vacuum line is good then possibly valve itself I had to replace one because it was stuck closed

-

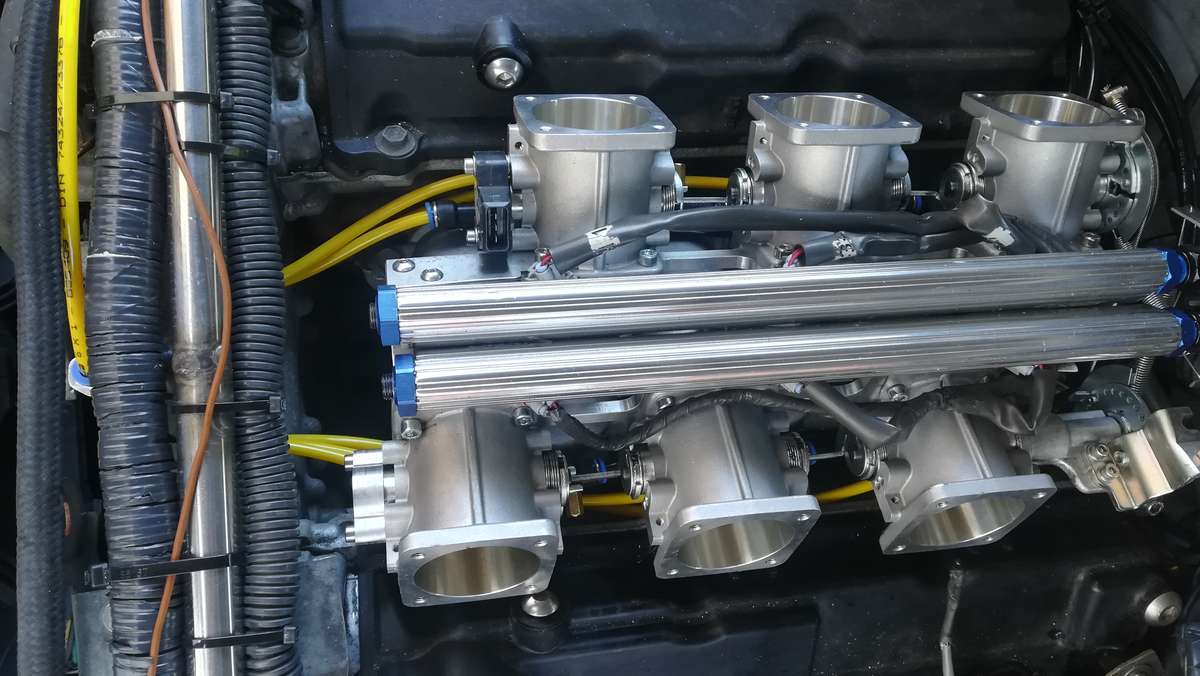

This is still on-going but I'm still having issues with high inlet air temperatures so far I've fitted insulating washers to the fuel rail brackets which has reduced the temperature of the fuel rails, fitted a motorbike cooling fan in where the standard airbox used to be which dropped the air intake temps by about 5 deg and the idle air valve now draws air in from the same place as the cooling fan so idle in traffic is now good until you touch the accelerator and it sucks in hot air from the engine bay I'm trying not to put vents in the bonnet but running out of options

-

41 minutes ago, Cimanu said:

I clicked for noise - soon I imagine I won't be disappointed! Looks awesome

I know it's overdue and I will do it soon

-

1

1

-

-

Dan I've thought long and hard about my response to this post, some of your choices have been questionable mainly the orange BMW with a bus shelter on the back but this is a step too far

Just hand over your Petrol head card and leave

-

1

1

-

-

I'm glad I caught this thread I was considering turning off notifications and deleting the link to the forum from my desktop too many people seem overly critical , overly aggressive or overly sensitive about other peoples opinions or comments about their posts.

banter is one thing and what I've seen lately is not that, so for the record I'm putting my work out there and I welcome your opinion, comments or good natured p*** taking and if I throw my teddy down there's a 99% chance that I'm just messing with you.

-

3

3

-

-

22 minutes ago, glrnet said:

I can't believe some of the childish comments I've just read on here. Some of you need to grow up! For the record this how you do it, Mopedmark, great job, great guide. Personally they are not for me and I wouldn't do that to my Zed but then some people probably don't like what I've done to mine. C'est la vie. Life is far too important to worry about who does and doesn't like my car. I do. That's all that matters. Forum:- a meeting or medium where ideas and views on a particular issue can be exchanged.

couldn't have said it better

-

1

1

-

-

12 minutes ago, Ben–350Z said:

Hey, been folliwing this (and your DIY topic) with interest.

At one point, I was wondering maybe one day (with money, time and a CNC machine or two

) if I could do it to mine, and kind of had a thought about cutting the "grooves" out of the bonnet, and replacing those with mesh to get cold air in there. Not sure if that'd let too much water in as well, though...

) if I could do it to mine, and kind of had a thought about cutting the "grooves" out of the bonnet, and replacing those with mesh to get cold air in there. Not sure if that'd let too much water in as well, though...

most of it is doable with basic tools and then things which were a bit of a pig you could just buy from jenvey then you just need a new ecu and a bucket full of patience (maybe 2 buckets) buying the obx kit and a new ecu with all of the other parts you'd need you could do it for about £2500 if you did all the work yourself

Go on you know you want to

-

1

1

-

-

This project has been a bit slow lately as I've had some issues mainly with the idle air valve which I had to install since going over to a cable throttle and air intake temps as the intakes are right above the exhaust manifolds

The idle air valve was causing fluctuations in the map signal that the ecu uses for load as there was a common vacuum manifold, I now have a seperate manifold I made for the idle air with 6 separate lines going to the intake runners with another 6 going to the runners for the common vacuum manifold which connects to the brake servo, fuel pressure regulator and map sensor that's a lot of plumbing so I did one in yellow lines one in black.

As for the high air intake temps I'm undecided, I either need to find the space to duct cold air in or vent the bonnet I'm open to suggestions but bear in mind that I'd like to keep it subtle

-

2

2

-

-

-

have you tried unplugging it to see if it actually disables the traction control ? if so the old ones had a 12 volt supply, use a volt meter to find the 12 volt supply cut the wire and put the switch in there well theoretically anyway

Annual Zed Shed BBQ Sunday 5th August

in Local Meets Across The UK

Posted

Ok I've run out of excuses and other people to throw under the bus but the dog did eat my homework.