-

Posts

6,670 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by AliveBoy

-

-

I'm going to deliberately waste it on purpose now

You HAVE to start a thread for it! Pleaseeeeeeeeeeeeeeeeeeee

-

1

1

-

-

It's probably easier for the customer to modify the end pieces surely? Otherwise you'll be in the difficult area of bodywork trying to get everything flat, corners correct etc. I wouldn't imagine anyone could complain as it's fairly reasonable to assume they'd need to adjust the end pieces themselves.

The issue is that the added "height" of the leather (and the thin foam beneath it) is preventing the end pieces of the plastics from sitting flush with each other when they're clamped back around the insert, because the insert itself is now about 4mm thicker than it was previously.

So what I need to do in future - should I do any more of these - is cut or file a step into the hidden ends of the insert so the leather will then end up sat at the same height as the original plastic. Does that make sense? I know what need to be done anyway

sorry for late reply, makes perfect sense, I was just thinking that if the onus was on the customer to adjust the end caps it would save you the possible ballache of doing it. However you're a professional and I'm not, so that's probably the difference

-

Nope. YOU are Dan, OUR Dan, THE Dan.

BASK in the glory, for YOU ARE DAAAAAANNNNNN!!!

-

2

2

-

-

Lewis Loughlin had it in his Z, I think he's currently selling his Z air ride kit which he's used very successfully on track. Unfortunately I don't know his forum name. Hopefully someone can help.

-

Can you lay down in the back of a FFRR?

Come on mate, you're in Essex! If anyone is gonna know the answer to that it's some of the ladies round your way

you can in the old discovery, can get a single mattress in there too which is very comfy!

-

1

1

-

-

-

Although I just googled it (why didnt I do that when I owned one?) and apparently if you pull the brake light fuse it will light them up. Go do it now

I tried it, didn't believe it would work, basically accidentally did a freaking HUUUUUUGE burnout... IN MY OWN ROAD!! Neighbours weren't happy!

-

4

4

-

-

Anyone know any car part shops that will have a DE thermostat i can collect?

Car overheated this morning and i really dont want to use the fiesta this weekend lmao.

Thanks in advance.

Try mike young, he might have a spare used one on the shelf

-

Well, that answers that question then - I do need to modify the insert itself so that everything sits flush!

I'll take that into consideration for any future ones I might do. It's a rather nice little finishing touch though, Andy - everything looks very smart!

It's probably easier for the customer to modify the end pieces surely? Otherwise you'll be in the difficult area of bodywork trying to get everything flat, corners correct etc. I wouldn't imagine anyone could complain as it's fairly reasonable to assume they'd need to adjust the end pieces themselves.

-

HI,

Only going by the link i have put up, if you change the width of tyre and nothing else then the rolling speed, diameter changes, anyways as long as you use some sort of calculator you wont go far wrong

That's because the profile of the tyre is a percent of the width. For example, if you changed from a 200/70R14 to a 300/30R18 the speedo will only be 0.25% out. Width does nothing, alloy size and tyre profile do everything.

-

Although only if I don't set the alarm off again

Just make sure to have the fob in your pocket when moving it around

totally my error

totally my error

-

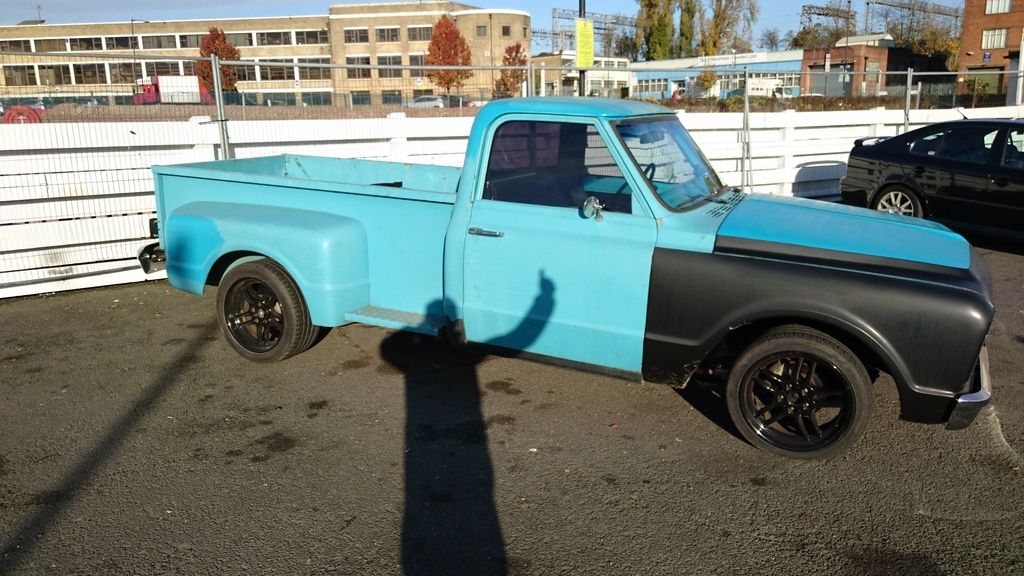

So in November I took the truck on the Fueltopia toy run, we chucked some toys in the bed and gave them to sick children. I got stuck in a traffic jam for over an hour and wasn't able to switch the truck off as it was constantly slow moving. Despite this, the truck was FAULTLESS!! The engine temp didn't get high once! Bearing in mind it's a 1960's truck and a 1970's engine I'm super happy.

some video with the truck in

On to 2017, whilst the roads are so salty I've not taken the truck out so far this year. I've got the new wheels and tyres on the way, I've got the rears and next month I'll sort the fronts. The main complaint from both myself and other people is the BMW alloys looking weird, so I've gone for the 15" steels above and I've decided to get 70's style radial tyres as the wrinkle walls would have been sketchy in the turns and apparently flat spot really easily. As for paint, I've decided to paint the truck satin black, it's easier than a gloss colour and it should match nicely with my NEW PROJECT!!!

I picked this up brand new on the 1st December and so far I've done 1200 miles. It's my daily ride so I can't do anything too crazy.

It's a Harley Sportster Iron 883, it's the baby of the Harley world but it still plenty cool in my opinion. Massive thanks to WINKJ for allowing me to pick his brains, providing links and being a general all round good dude as he has the same bike.

I even rode it in the snow

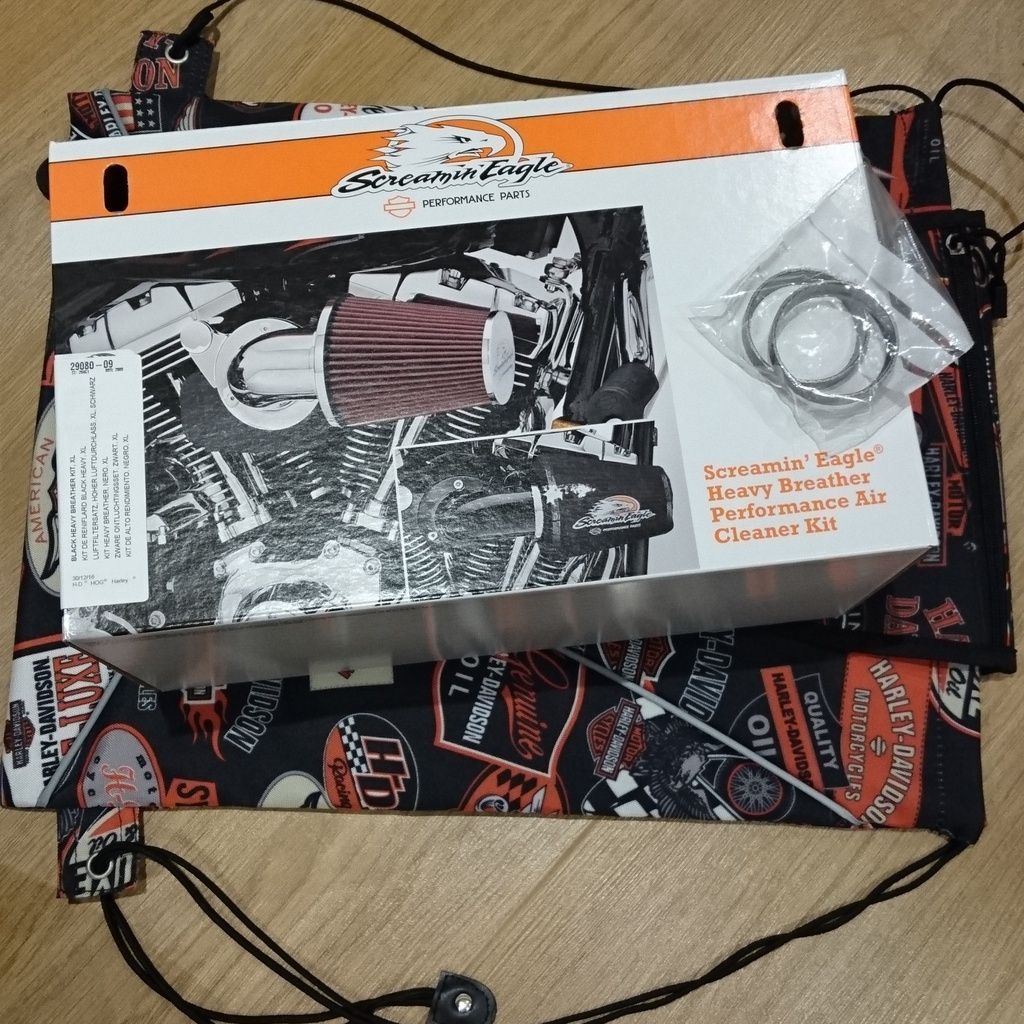

I've already got new bits for it!

Vance and Hines Short Shots and an FP3 Fuelpak which is like a self tuning module, I then had to nip to Harley to buy some gaskets for the new exhaust and I accidentally did an impulse buy...

Harley Davidson Screamin' Eagle heavy breather.... and a lame bag as I hadn't planned on buying anything big so didn't have one on me

The projects together, pre bike mods! (yes it's filthy!)

-

2

2

-

-

You can, however I have no idea how to package it to ensure any of the little fiddely bits don't snap off. I'll have a look at home to see if I have any boxes I could use to put it in.

-

2

2

-

-

If you want a standard DE airbox, PM me as I have one you can have for free. Collection only from Woking in Surrey.

-

Ceramic floor tiles can look the nuts, not cheap, but you'd probably never have to do it again.

-

Both him and Dblock came back after their temp bans, Dblock only briefly though. WW always used to tell thinly veiled racist stories which were clearly fabrications of his own mind, one day he got called out as a liar, so he went on a tirade full of swearing at another member via pm. He then got perma-banned. It was a long time coming

-

1,000 times agree with Will, don't go to Guildford Nissan. I've always found Aldershot to be good though. If it's just servicing and the like, I and a few other members can help out (that goes for any member in the area!)

-

My truck is called Daisy, because she's a cow, although it was called mistress whilst the build was going on...

"Where's Matt tonight?" "He's at the unit with his mistress" or "Going to see the mistress for a few hours"

The Harley is called Harley

My wifes KIA Picanto is called Kia

My first 350 was called Sally and the second one was called Sally 2

-

1

1

-

-

All the northern ones rusted away already

Best ones are in the South. Mine is for sale on Pistonheads although I do have someone coming Sat who wants it...

Not on the forum? You're always telling people to buy a car on the forum as it's safer

-

2

2

-

-

I ran a welder for 2 years on mine as a daily, never had any issues, supposedly hard mounting the diff is what causes so many breakages. Had regular track sessions too, I toasted two clutches in that time, no diffs or shafts

Great news then. When you say hard mounting the diff you mean solid diff mounts, so just stick to the stock rubber diff mounts when running a welder? Also how low are you running the car?

cheers

Yeah, leave the rubber mounts I'd say. I had BC coilovers and the rears were as low as they'd go down.

-

Does it have the correct CCA (Cold Cranking Amps)? If you don't have enough CCA it will struggle to start the car regardless of voltage.

-

It's more that higher octane fuels require a spark at a different stage of compression compared to lower ones. Having lower octane fuel means that the ignition needs to be retarded to avoid detonation at the wrong part of the cycle or as others have said "Knock". When super unleaded fuels started coming out most manufacturers put knock sensors in the cars so that the ECU would fix the timing itself, unfortunately Nissan were a bit late to the party, so in the early Z's you have to be careful.

In theory, changing the spark plugs to a colder set could help with preventing knock, the higher the octane of fuel the harder it is to ignite, so a hotter plug is required. If you're using lower octane fuel a colder plug would fractionally slow down the ignition of the fuel, in practice, I don't know if this would work or how to work out the "correct" plug to do that with.

-

Move closer to the garage?

-

1

1

-

-

Just to annoy Dan

in Off Topic Discussion

Posted

He's on 24,999!!!!