-

Posts

1,537 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by SteveW

-

-

-

That's fine mate.

Enjoy Le Man

Thanks

-

-

I am also trailing the Redex fuel treatment fix. After 1 treatment the gauge does appear more accurate but not yet correct. I will feedback progress as the trial continues.

-

That is disgusting, some people have no scruples!

The whole forum is built on trust and respect. Maggots who abuse the trust of others and blatantly misrepresent an item for sale are despicable.

-

1

1

-

-

Good shout, it's worth a try saves you stripping it all. I might have to give it a go as mine is all over the place again. Which Redex did you use?

-

Ha ha I will indeed. Looking forward to hearing it but I must wash mine first or I'll be ashamed.....

-

Ps I agree with Sam reset the codes and see if they come back.

-

Hi Adrian, strange finding you on here lol.

Didn't think about this last night but ABS/TCS could be caused by wheel and tyre combo. Zeus are very particular.

What size are you running on the 19's?

-

Thank you Alex and GLR I assumed it was going to be one of the smaller clutch related components, will make sure both get done when the clutch gets swapped.

-

1

1

-

-

Release bearings are notorious for being noisy, most are audible when in neutral with engine running, not really a cause for concern.

This isn't the normal release bearing rumble, this is very different. I probably should have said I've had the car 6 years. Thank you for your response though as I'm sure there will be a fair few soon to be owners who were unaware of that normal noise.

-

Happy Sunday Morning folks.

I've got a bit of an odd problem,has anyone ever heard of this before?

On some days, does it more often when cold, when I start the car I get a deep rumbling sort of grinding sound from, I assume, the clutch release bearing.

As soon as I release the clutch into any gear or neutral the noise increases in frequency/pitch proportional to how much the clutch is released. As soon as fully up the noise goes completely. It only does it once on initial start up and never again whilst driving.

Thoughts, worn release bearing? Anyone had this before? It's been doing it for a while now.

It's at 87K.

Cheers

Steve

-

Hey guys only just seen this, I apologise for my tardiness!!!

Thank you all had a cracking day!!

-

1

1

-

-

Payment sent

-

Hi mate if still available I'll take them.

How would you like paying?

Thanks

-

Will only get long term gains with a remap.

-

Forgot to post this a while back.

Had cracking service from CMS and would recommend to any and everyone.

Thanks

Steve

-

1

1

-

-

Thanks Alex and Azure I guess it means stripping the car down again lol, should come apart easier this time at least.

I'll get in touch with CMS, as always Alex you have the answers!!

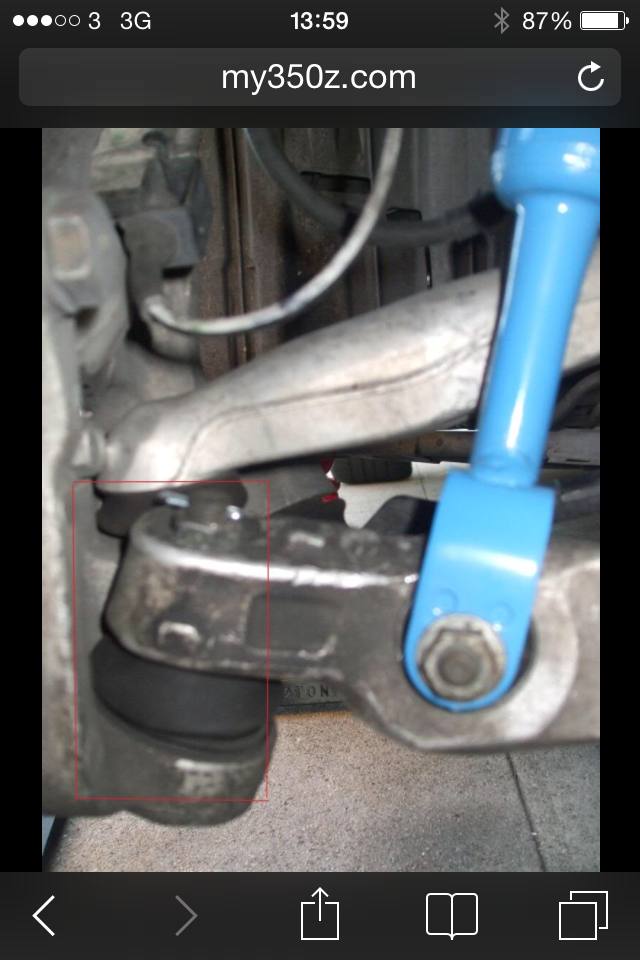

Hensh thanks for the feedback but this is the ball joint mounted on the steering knuckle and not the banana arm .

-

Well after spending 8 days and nights replacing all my front end bushes for Superpro I still have a rattle /knock.

Doing the bushes was a nightmare!!!! Everything was corroded to hell. Even had to cut things off, not good.

I think this ball joint is the culprit of the knock as all other seem to be in good nick and this one was passing some grease when I had to drill a broken drill bit out of the split pin hole....

Can this ball joint be replaced or do I need the whole assembly?

Thanks

Steve

-

No, sorry, I did the whole arms as the ball joint is the same age as the bush... Cutting was more than an option in my case... I cut the arm and the rubber and took the grinder to the sleve...

But try this...

Drill the rubber, take hacksaw blade, cut out the rubber, that removes the arm then grinder to the sleve, just be carefull not to cut too deep, not pretty but that arm has to come off...

Agh yes that now makes sense. Ball joint seem to be in good shape so just doing the bushes at the moment.

Good shout on cutting the bush.

I was thinking it may be easier to destroy the bush to get the arm off then I can at least fit the new bushes and get the mole grips and grinder on the sleeve.

Cheers

-

Could it be ally corrosion?

-

I had it the other week from some toffee nosed cow on some country lanes.

I was doing about 25 as it was muddy on the roads and I blipped the throttle on a down shift. She jumped out in front of me and said slow down, to which I asked if she was telepathic and could read my mind. She said no so I asked how she knew what speed I was doing? No response from her. So I said get your facts right before challenging someone and by the way when you walk on roads you should walk towards traffic, not with it coming from behind.

-

Sadly Gareth that wouldn't work, I've been trying to get a chisel in between the underbody and bush without success.

-

Thank you for the suggestions.

Sadly I don't have a welder or a ramp as I think that would be the easiest.

I'll keep plus gassing it, heating it and giving it a tug over the next few days and hopefully it'll penetrate and come loose. If it doesn't I think it may have to be a garage.

Jixamam How did you go about grinding the bushes? Through the rubber at the bottom and into the sleeve inside? Would have to be careful not to damage the shaft the bush slides on.

Thanks

[SOLD]Bluetooth Module and Banana Bush

in 350z Parts For Sale

Posted

Bush Sold

Bluetooth module still available

Thanks