-

Posts

317 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Everything posted by Nismoandy

-

The the steering column on the driver side does fail with a universal joint is on the manifold so we are going to alter. I do have a couple of Solutions to this problem.

-

Next stage is to Mount the gearbox properly on the new mounts and check all clearances with engine and firewall to make sure good clearance. Also to get the manifold test fitted as I'm sure I'm going to have a problem.

-

Me to Paul long way of at the moment

-

-

Now I'm going to have to manoeuvre the engine turn it around and put it at an angle so that the gearbox is pointing downwards so as to allow easier entryps not easy believe me

-

The engine and gearbox is together now . We need to put the engine mounts on and and put the engine in here we go. Make sure you get the engine mounts on the way round and the right way up easy mistake. The instructions are not very clear take your time.

-

It's massive don't remember it being this big

-

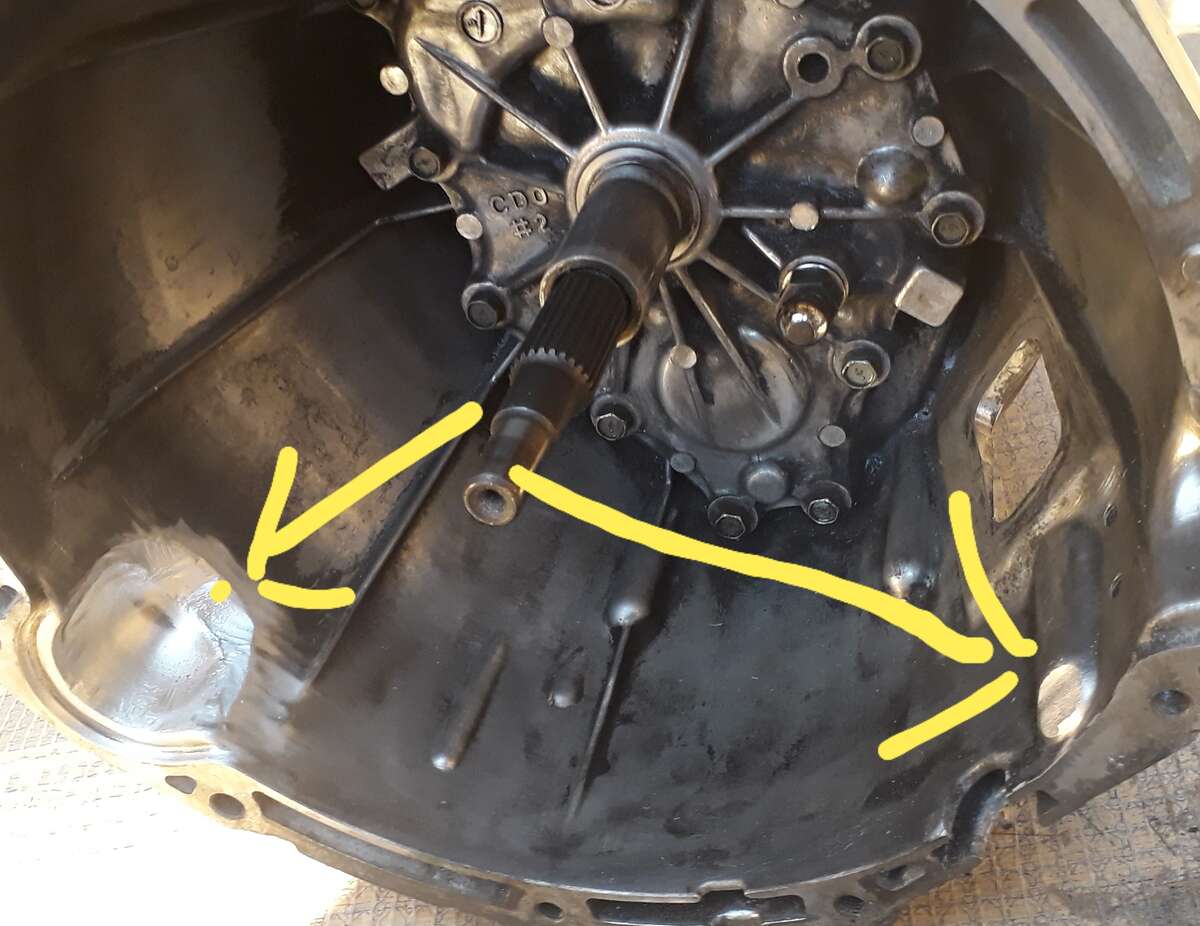

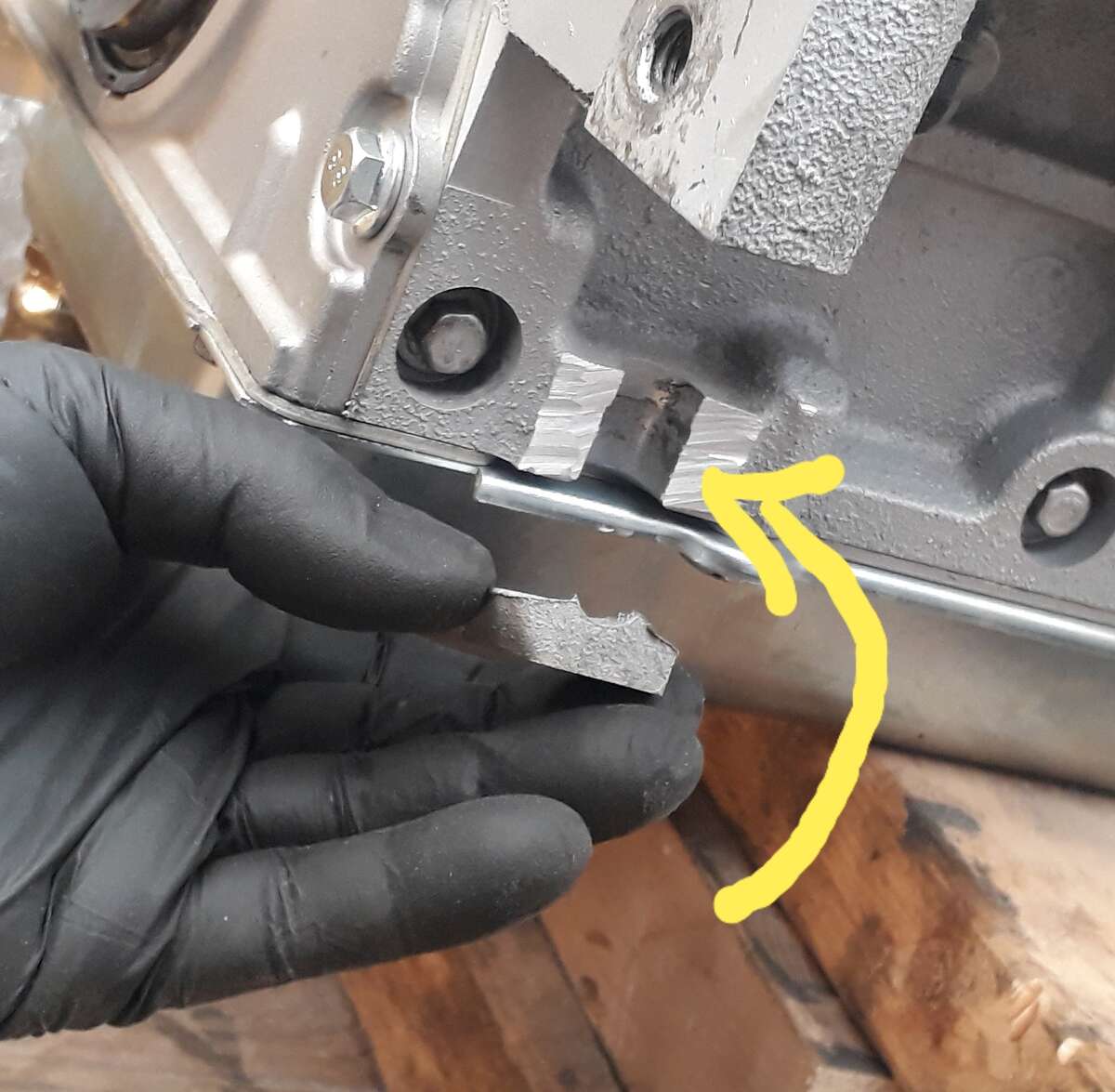

Now to put the gearbox and the engine together, i had to replace the thrust bearing carier as it was cracked. Also you have to take a little bit of metal away from the inside of the bell housing arrowed below . This is to allow clearance for the flywheel and and starter motor.

-

Flywheel and clutch installation. You have to clean flywheel and pressure plate with alcohol. Flywheel bolt down to correct torque , align clutch and bolt down pressure plate to correct torque as well . I am using exedy clutch as is original fitment for 350 just upgrading to racing clutch to cope with extra torque, that the engine will make.

-

-

-

hi everyone moving along now we are starting to put the engine and gearbox together. Also smaller jobs. First job was to replace pilot bearing

-

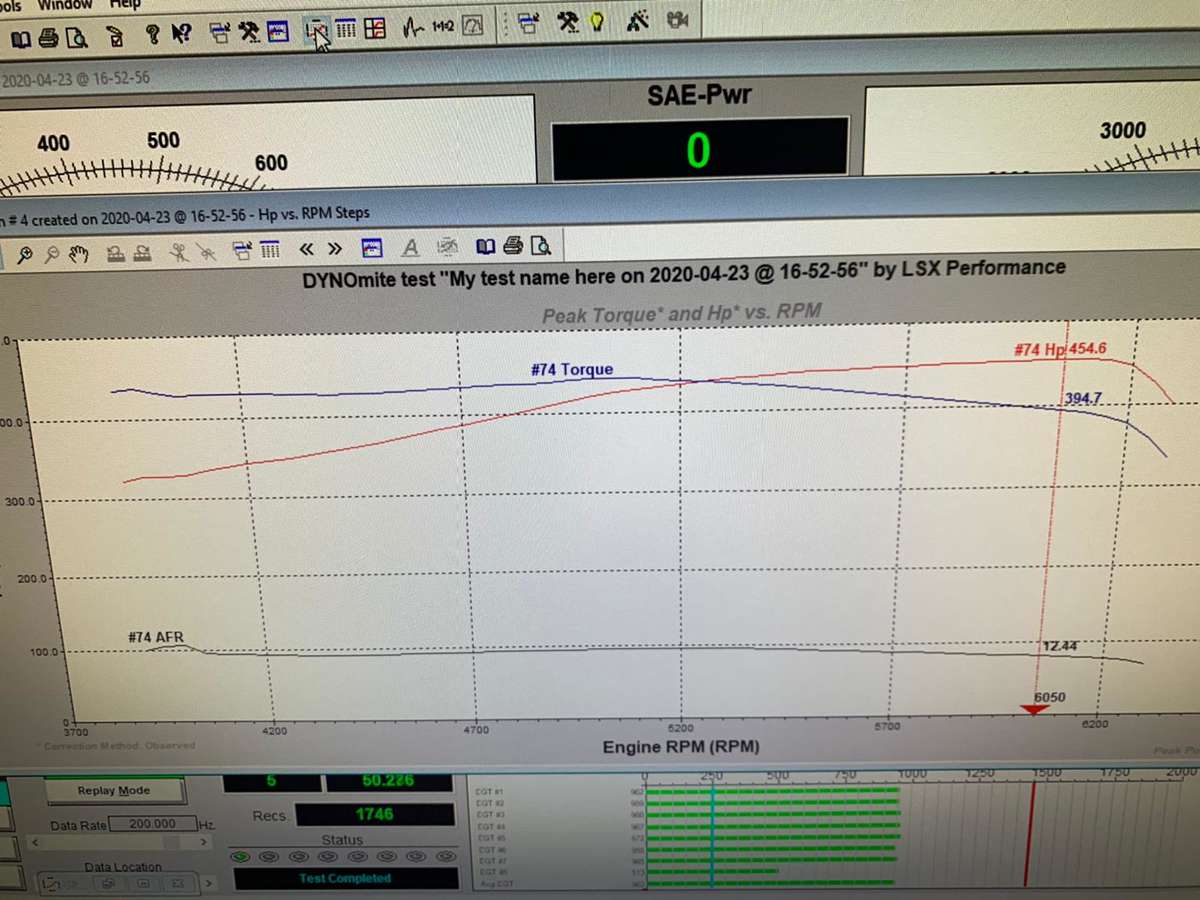

Lovely results

-

No problem all sorted thanks

-

After you have installed the shifter. Check Gear shifts to make sure all is ok

-

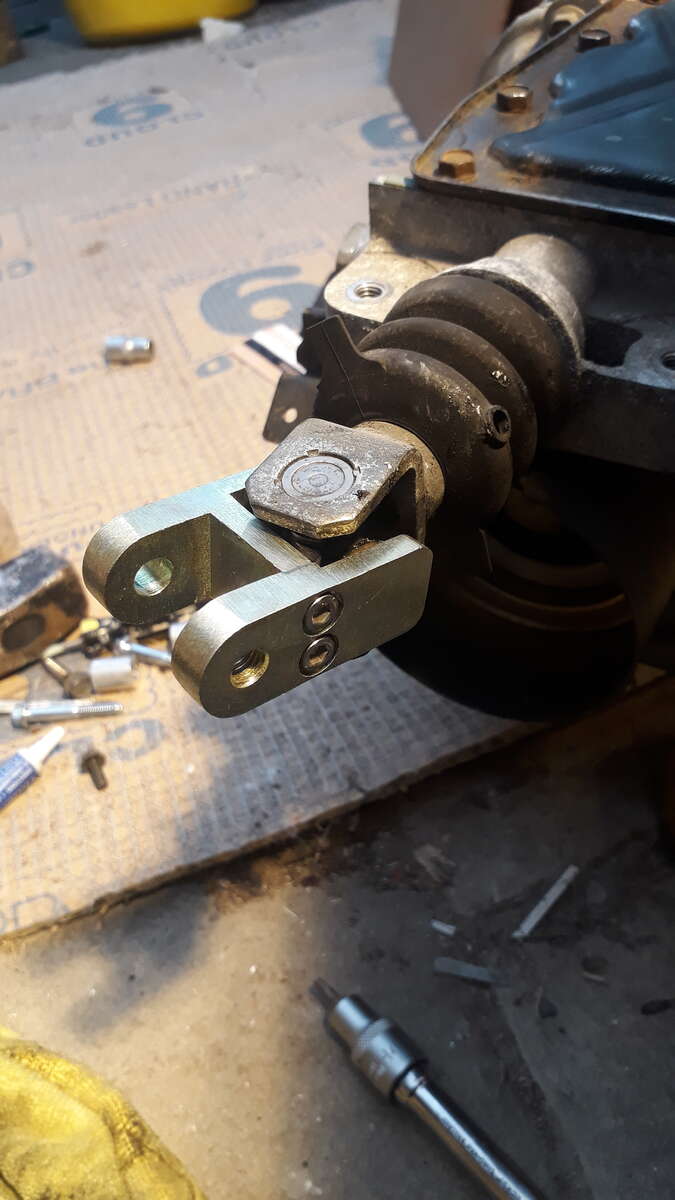

Next on the agenda. Is to replace stock gear change with shortened and I SR shifter I have arranged the photos so you can see the dismantle of the existing Shifter and cradle and then reinstalling the new shifter and cradle. When the engine is reinstalled the reason why the the gear shifter is shortened approximately by 2 inches is because the engine and gearbox is further back into the car. This helps push weight into the centre of the car , we'll see about that at the end of the day, I will weigh it to see difference between stock and ls build

-

-

-

Thanks Andy

-

Thanks, i hope so to with out too many problems ahead

-

Just a couple of photos of the engine just finishing off the build and the other is it being installed on the dyno

-

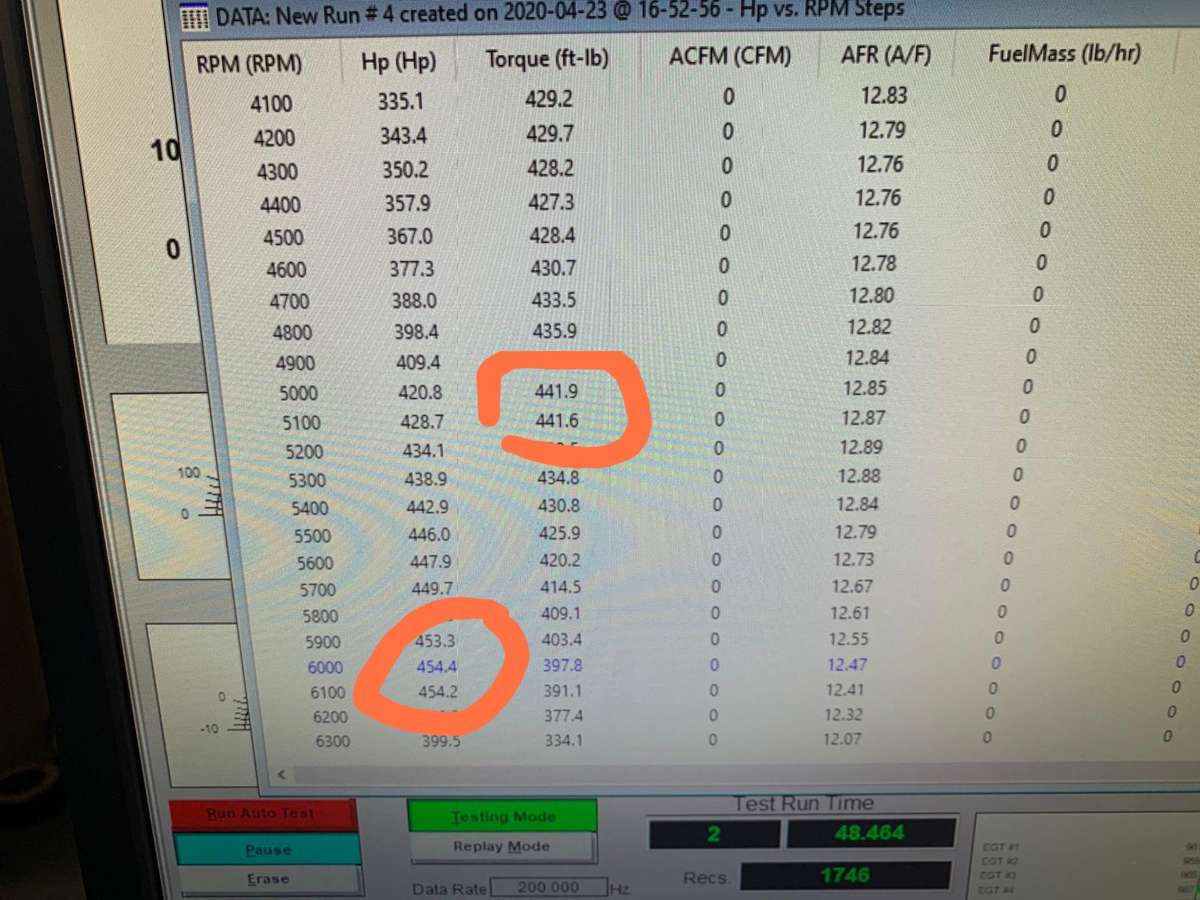

The dyno Run produced 454 BHP and 442 Torque pounds . Once installed it will have a final dyno tune to allow for exhaust , gearbox, etc..im extremely happy with the result and hopefully i Will be able to install the engine SOON

-

Last video is of the dino Run producing the safe map for the engine before it gets installed into the car. I say safe map this is where the engine is not tune to it ultimate Power just so that it can be installed and run with safety in mind, and then when the car is finished it gets tune to his potential

-

this video shows the The fly by wire 350Z throttle pedal working with an LS3 throttle body on an LS1 engine . This allows for better throttle response and delete the throttle cable

-

Hi sorry it been a long time ago I put a progress report about the Ls1 swap . The above video is of the newly built engine on the dyno. First video above is of the engine being revved checking oil pressure water temperature and getting the fuelling correct with the new ECU