-

Posts

2,337 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by Mark@Abbey m/s

-

-

The only thing wrong with the DIY install is the car wont pick the fuel up from the other side of the fuel tank it needs the fuel pressure to be returned from the return pipe where the stock fuel pressure regulator is situated like in the CJ kit to syphon the fuel across from the side of the fuel tank without a fuel pump.

Good info thou.

-

It isn't just the fittings you need;

As people had said the fuel pump module needs modifying; it does a lot more than just hold the fuel pump;

Snippets from CJ web site;

Far better to buy the kit from CJ and everything work. I feel it is a PITA to be in and out of the fuel tank

One thing buy a new fuel pump module sealing O ring they absorb fuel and swell up making them a right pain to fit;

-

Not as easy as just drilling the rail Tricky.

Need all the stuff to convert the fuel pump assembly.

Fuel return line as well and a fuel pressure reg

50 is completely different to a 70 as well.

-

Easy job. What input you going to use?

Let me know what you want to do.

-

Cheap deal finishes end of 2015 , goes up to £500-00 inc vat for 2016 onwards.

Book and pay deposit before the 24th or via PM before the start of 2016 to get this current discounted deal

-

We have a pair of used Berks HFC's for sale on behalf of a customer , removed as they where to raspy for the customer.

They have done 19K cat bricks still tight in casings;

New gasket set included looking for £225-00 including shipping.

Thanks

-

Commander, Hi. Where are you based in the UK?

-

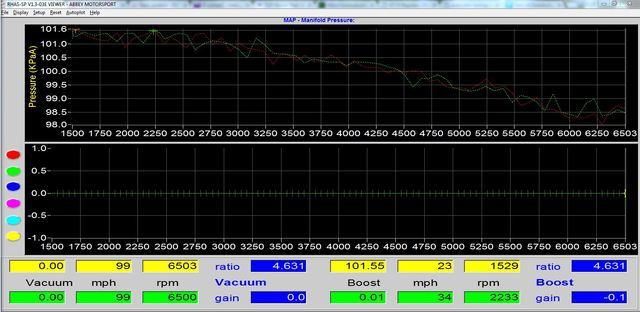

Big torque number is hub torque. Basically engine torque X drive ratio (gearbox X final drive) = 4.631

Divide hub torque by 4.631 you get flywheel torque.

-

Hi Mark, what about for an HR, as it revs higher as standard?

Bobby what are you thinking then? The HR gives a much bigger spread of torque then any of the other 350Z motors and with normal bolt ons will give 270/280 hub bhp easily , I have tuned a HR with PPE headers (don't know if there where the cheaper or more expensive merged collectors thou) car gave 290 hub bhp I seem to remember.

Again stock air boxes work best we have found.

-

Could be a carbon build up on the inside of the butterfly flap? Get a bit of carb cleaner and give the throttle flap a clean if you have no joy with lubricating the pedal.

I cleaned mine during a service the other day and was surprised at the amount of crap I cleaned out!

the throttle pedal isn't connected to the butterfly with a cable , as Olly has said the car is fly by wire so no hard connection between the pedla and butterfly.

-

I think you may see around a gain of 10bhp though out the rev range;

Limiting factory will be rev limit , these cams will make the car want to rev on and the stock Alloy valve caps wont allow more than 7100rpm we feel.

-

Some people Ray's fit over the 370Z brakes others say they don't Olly.

Even running spacers may help the Rays fit.

-

None of the DE(278bhp) powered cars where facelift models. Facelift was brought in for the RevUp(296bhp)powered cars. The GT4 model cars had early dash trims and early front bumpers. The normal edition cars had facelift bumpers and updated interior trims.

-

The world is doing it.... Just not the UK.

Don't want revup cams for the 340, need some very wild ones, like jwt c8 and above.

But thank you all for highlighting why no one on this forum tunes na.

Rather than approach it with 'interesting, no one here has managed that yet' you ridicule and shout it down.

The 'specialists' in the UK haven't really tried the right mods in the UK yet to get power.

Sorry but to fit cams into a 350Z motor is a lot of money , easier to do with the motor out in our opinion;

Then if your running wild cams you need to run more compression as the static compression will be dropped as the cam is wilder; new pistons needed;

I know Sasha when he was running his own company used to tune on a Dynapack. Used to throw idea between us. They used to use SAE conversion which will add around 10/15bhp to a bhp figure;

Your end up with a motor with a engine with a 2000rpm power band max that will not be nice to drive at small throttle openings and low RPM's , will require rev to make it go properly;

That's why us UK tuners always say go FI makes a more fun car easier to drive quickly on the road , but if the car is going to be a track car/race car yeah go for NA power but your also need a sequential gearbox to make the most of the narrow power band.

I did manage to run a car on our in house dyno today and recorded Vac in the plenum , reading in Absolute KPA we saw a increase in Vac from 0 to approx 0.003 kpa at the rev limit such a small increase , my thought is it the TB or the plenum design;

Same car recorded 270hub bhp thou pretty good number for a DE motor , circ approx 310 flywheel bhp , stock motor , headers, ART decat pipes, plenum spacer,stock airbox with velocity stack, Milltek system and a very good reamp with UPREV. a Stock DE will give around 235/240 hub bhp we have seen from all the cars we have run over the years.

-

2

2

-

-

rev up is just a better quality pump gear materials no different in flow.

Nismo has increased flow over stock DE/REV UP oil pump.

I will check a DE for a VAC at full throttle when I next get one on the dyno for a retune.

thanks

-

Limiting factor in DE rev wise is valve Spring retainers and collets. Seen failures at 7100/7200rpm when used on track. Spring retainers are alloy in stock form.

Stock rods will go to 7500rpm no troubles in NA trim.

High RPM will cause oiling issues as well.

-

Even stock the de pulls a huge vacuum in the plenum I believe which isn't good on a na engine.

at wide open throttle?

-

Has anyone in the UK ran proper long tubes with the aim of getting power? I'm genuinely interested in their findings if they have. Was it on a revup or normal de? If de did they add cams.

Only car so far we have run PPE longtubes on is a HR motor , running stock cams and a Cosworth manifold only works on a NA car above 7000rpm and the stock cams wont work up there. Running TB's on stock cams work thou. But the Stock ECU wont run TB's but Link make a Plug and play ECU that will allow to run TB and even keep fly by wire.

-

Good debate;

If your going to fit headers PPE long tubes are the way forward with the parallel merge collectors , these make good bhp but are also super loud and I am afraid a motor out to fit and you cant add Cats for MOT time

We have a set to go onto our 350Z Rev Up race car but we haven't had a chance yet to get them fitted.

I have tuned a couple of HR with the PPE Long Tubes fitted and we are seeing around 300 hub bhp with only bolt on parts and the Stock ECU tuned with UPrev so around 340 flywheel BHP which is pretty good for a NA car nearly 100bhp per litre on pump fuel

One thing thou guys , lets compare BHP corrections , if we all run in SAE us Brits that cant tune will gain around 10 to 15bhp @ the hubs so with a DE with bolt on parts which we are now regular seeing around 260 hub bhp which we estimate at 300 flywheel bhp will raise to 275 hub bhp. easy way to make number's.

We have built a 350DE that made around 320 hub bhp still running the stock tuned ECU , made max power at around 7200rpm from memory, cant remember the reg number thou.

With the DE you can see the way the power rolls over around 6500rpm it is limited with flow , to make more power it will need to see more revs to run more revs it will need a wilder cams and supporting mods and if your running wilder cams it will need more compression. Also the flow on a stock intake port DE cylinder head is better than the flow on a VR38 Cylinder intake port , the drag car we used to run ran totally stock DE heads with better quality valves it flowed that well remember these motors are around 85bhp per litre which a few years ago was FI numbers.

To make 340 whp it you need to get inside the motor it is doable easily but will cost you.

I know Bob from RJN very well , we tune all the 370's for him he runs for Nissan Sony Playstation with ECUTEK , I have also helped them out with there old 350Z HR proper race cars with IES built motors we was seeing around 350 hub bhp with these (these we engined dynoed at 400bhp) so it is doable just will cost money far more than adding FI;

We also build some DE's motors for a team that runs Chevrons in the British GT , built DE motor rods/pistons/dry sump/Jenvey Throttle bodies but stock cams running Life ECU, these will see around 320 hub bhp this gain is from running TB's power still rolls over at 7200rpm thou but we see a flat torque curve from 2500rpm to 6000rpm.

-

1

1

-

-

Only way to check ECU is correct is by reading ROM number we have found if you can't get a chassis/reg number.

-

Lee,

the issue is the ROM loaded into the ECU.

If you have a manual JDM the ROM number will need to be either CD405 or CD $15 only way to check this is to either get the Chassis number from car where ECU came from or we can read the ECU.

I would need to read both ECU's though

If the ECU is correct we can up load a Uprev licesen to turn the NATS off no problem.

-

Hi, the issue you guys are talking about is due to the exhaust cam control issue.

We have noticed that the exhaust can control PID closed loop program is too aggressive. When the ECU takes control of the exhaust cam it retards the cam initially to far causing the hesistation(stutter) as the cam position isn't ideal for a short period.

We do have a work around on this issue it does require a UpRev remap thou which allows us to modify the exhaust position map so removing the hesistation.

Uprev cost is £402-00 Inc vat which includes dyno time to retune the ECU for best performance.

Anymore questions ask away

Thanks

-

1

1

-

-

Cruise works like normal , to switch maps turn cruise off , stop the car then switch the maps;

Traction is turned on when turning ESP off (depends how you have set the ECUTEK up)

Then when the Traction is initiated with the cruise turned off you use the cruise toggle to adjust the traction control aggressiveness.

Thanks

-

1

1

-

-

That is about right on a DE, the cam set up and breathing on this motor will cause the power to roll over around the RPM you are seeing.

To get the motor to rev higher will require a motor rebuild with different cams/Spring retainers and collects, different design manifold headers. Stock motor is only safe to 7200rpm due to alloy valve Spring retainers.

Far to much work to get a small gain.

Any more questions PM we can then keep this thread clean for OP.

Thanks

My Little weekend project.....

in Member Build Projects

Posted

djtimo you got Syvecs fitted and tuned yet on the Zed?