itsLeon

-

Posts

82 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by itsLeon

-

-

20 hours ago, RobPhoboS said:

Glad everything is pretty much sorted with this !

Prior to dismantling my engine I had also done a similar thing with the intake (although my filter is by the crash bar). If the car is sitting I think you'll just have the slightly higher intake temp until it's moving.I also wrapped my PPE headers and have some flexible heat-shield stuff that I'll put over them once my engine is built.

Actually hoping to finally pick up my heads today ! (9 months later!!!)

Yeah i think the problem is that it is sucking in hot air at idle because the heat can't go anywhere. Should be easily solved

Good te hear that your heads are finally done! Can't wait for your build

-

1

1

-

-

Photo's from the intake:

The intake now is a 3.5 inch steel intake (can't weld aluminium yet) wrapped in heat reflecting tape with underneath a heat shield.

The 'heat shield' near the filter is a bucket from a local construction market.

Still have some issues with heat soak so gonna change the steel pipe for some plastic pipe to see if that makes a big difference. The other solution will might be a ebay electric intake turbo thingy to give enough cold air to the intake (by blowing away the hot air surrounding it)-

4

4

-

-

Update time:

Started mapping the new engine and the break in of the engine. Found some small problems like to high air intake temp and oil leakage. But other then that engine seems to behave great.

-

6

6

-

-

So we got the idle ready. Gonna continu tuning after 2 weeks.

-

5

5

-

-

On 27/08/2020 at 01:12, Nismoandy said:

Bit more progress coming together now and the engine bay is looking tight. I have changed the stock fans to Mishimoto it also helps with extra cooling and clearance, for the air intake i probably will change the size of the intake and colour of the pipes? Not sure yet I'm just concentrating on getting this up and running still waiting for a few parts but not many

Did have a play with the running and seems to be working nicely

If you ever get heating problems, change the mishimoto fans back to OEM (if its fits) because my experience with them is that the OEM perform better.-

1

1

-

-

We have started the engine for the first time

-

3

3

-

-

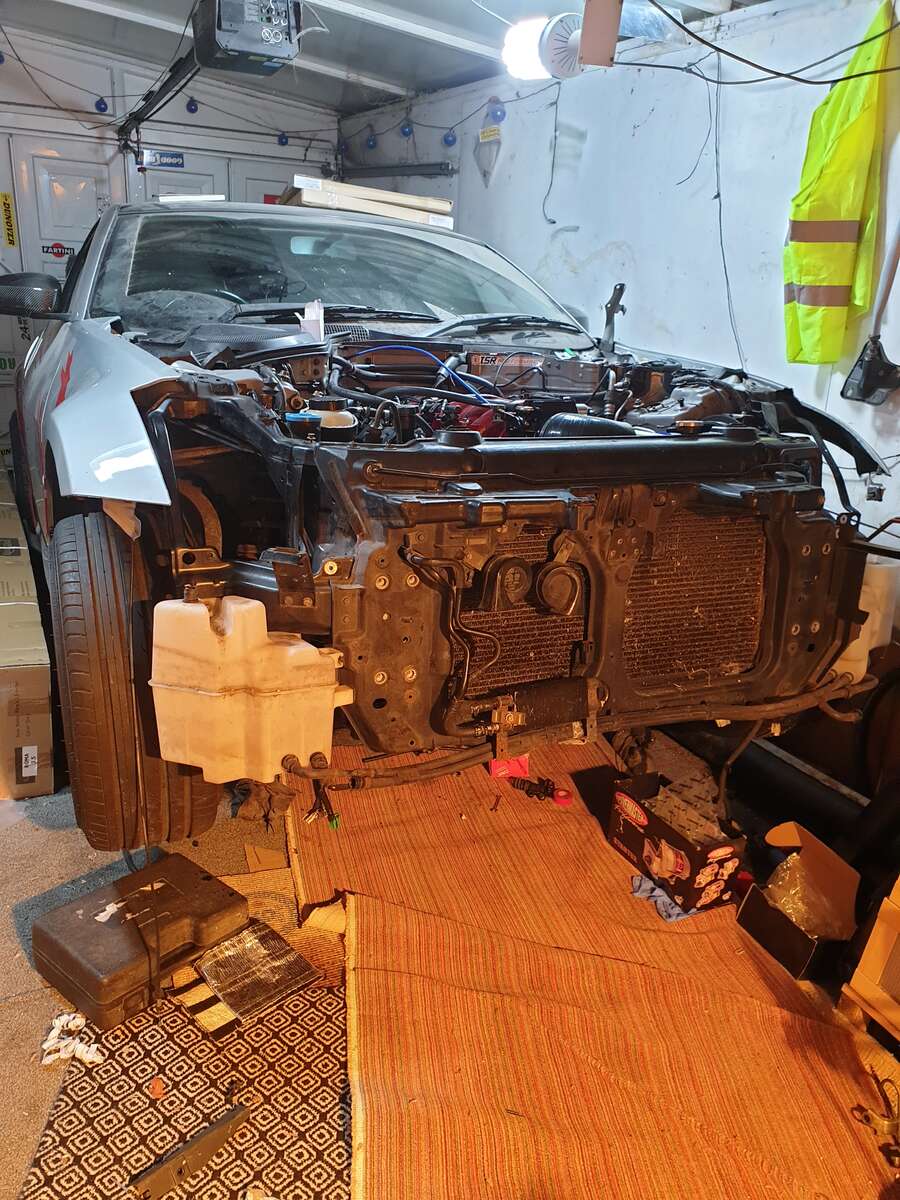

So the engine is in, most of the wirring is done, custom intake also done expect to start the engine this Friday

-

4

4

-

-

Small update again:

The engine is in, transmission is also installed. Now working on the wiring.

Parts to make our own 4" intake are being shipped, new laptop also ordered for tuning use.

I estimate that at the end of the month we can start the engine for the first time

-

3

3

-

-

25 minutes ago, harryjackson said:

What headers you running?

Those are ISR headers didnt have the money anymore for PPE

-

1

1

-

-

So the engine is almost done, will be starting this week to put the engine back into the car

-

5

5

-

-

Damm dude that is some serieus cleaning you did!

-

1

1

-

-

So finally found some time to start working on my car again.

The old engine is out of the car so now we can start moving some parts over the new engine. I expect this to finish within the coming 2 weeks and then we start the proces to put everything back into the car.

-

2

2

-

-

Finally it's done!!! Took a day of from work so me and my buddy could spend all day on it and we finally have the cams installed and the timing chain is placed and triple checked to make sure everything is according to spec.

But my God that was hard, none of the OEM markers are in line with the new cams so we had to calculate everything from scratch.

-

6

6

-

-

On 01/03/2020 at 11:18, Nohotz said:

Thank you. I did not post this with the intention of offending any company at all. I have actually been talking to Horsham, Jez. As I am not in the UK I have no experience with Horsham. I wanted to post this and see what other people thought about it. Just to make me feel better when sending the ECU

I appreciate your answer!

so where are you from? maybe i know a tuner in your location because for some reason most tuners i know are very hard to find.

-

Small update:

We have a problem installing the cams with the correct timing. Already called the engine building company's but they can't provide a solution...

The problem we have is when we put on the sprockets the timing will change when we tighten the bolds. But one company (specialized in old American cars) is coming to help to create a tool to have both the intake and exhaust cams fixed in place. -

40 minutes ago, RobPhoboS said:

How did you end up discovering they required different timing ?

I know the duration of your ones are much higher than my C8's.Well when we first timed the cams and installed everything we did a check if everything was oke. We then found out that one head was wrong and started to discuss about the cams and the fact that these cams are missing the little knob for the sprockets. After contacting the manufacture about it they told us how to time these cams.

so basically we found out by accident.

For your cams i would suggest you send JWT an email if it needs special timing or if you can follow the Nissan manual for timing the cams. My bet would be that you can just follow the Nissan manual because i haven't heard this case about the JWT cams and the fact you can still use VVT if im correct. -

Time for a small update.

We discovered that the cams need different timings then the Nissan manual describes. So we contact the manufacture on this issue and started over...

We need to find to absolute TDC as show in the image below and then time the cams by how much they push valves down @TDC. So tonight we will once again time the engine.

Also new parts have arrived (EGT sensors)

-

2

2

-

-

Little update:

- We have changed the main bearings- We have cleaned most of the parts (such a fun job todo...)

- start assembling the engine.

-

4

4

-

-

Will follow this build!

-

1 hour ago, 350Butcher said:

Cheers for passing this info on...........however I wont be opening up my clearances. My opinion is, that opening them up and especially for the reasons of increased load and revs. You'll just be losing oil pressure and wearing out the bearing faster as the load isn't spread as well across the bearing surface as with tighter clearances.

The only advantage of increasing clearances would be additional cooling due to higher flow of oil but at a far higher cost to dropping the oil pressure. In a "modern engine" the components and obviously with the use of high quality oils the heat can be handled so isn't so much a consideration as if you were building say an old war time classic car engine for example.

As always just my thought's on it........it's your build and I'm following it with interest.

Just passing the info i can find.

Well it was a though decision to make to change the bearings but the 'old' ones measured a clearance of 0.0015 while the minimum must be 0.0014. So the new ones will be around 0.0025.

We have seen a couple of spun bearings here on build engines here with OEM spec clearances so people told me to go a little bigger.

In the article i linked they say:QuoteThe optimal range of clearance is 0.0015-0.003” (for a bearing with 2” diameter). Looser clearances are more suitable for highly loaded engines working at high rotation speeds and with thicker oils. Tighter clearances provide a better combination of hydrodynamic parameters in less loaded engines working at lower rotation speeds and using thinner oils.

This was for me the reason to go a little bigger.

In my research i found that there is a rule of thumb (https://www.enginebuildermag.com/2017/03/high-performance-engine-bearings-2/).QuoteMost rod and main bearings run best with .0007˝ to .001˝ of clearance for every inch of crankshaft journal diameter, or .0015˝ to .002˝ inches of oil clearance for a 2-inch diameter shaft

My crank is 2.36 inches so that calculates to a min of 0.001652 of needed clearance again higher then what i have currently.

-

On 12/01/2020 at 21:56, harryjackson said:

Any updates on this @itsLeon

Well yeah i got an update.

After talking about clearances with alot of people and doing some heavy research on it we decided to change to main bearings again so that we have more clearance (from 0.0015 to 0.0025) because of the higher load and much higher RPM.

@350Butcher is see that you have the same clearance as me, im changing that based on this article (and talking to king etc): http://www.substech.com/dokuwiki/doku.php?id=oil_clearance_and_engine_bearings

Other news.

Yesterday i picked up some new buckets because still some aren't in spec. So hopefully i can finish the heads tonight.-

3

3

-

-

37 minutes ago, RobPhoboS said:

Is the 'ghost cam' for a lumpy idle ?

Yes. its kinda useless but from what i hear around me people want it because they won't invest in expensive camshaft swaps.

-

Update about the software.

- Pops and bangs. Didn't see much improvement.- Shooting flames. Didn't see anything. We do suspect the exhaust for this because its our "be quiet on dyno exhaust" also know as OEM.

- Ghost cams. While we did manage the lower the ignition timing (to 5) on idle we suspect there is a special idle table we haven't found yet to get this to work. We might try in the futher to play with the VVT to give the desired effect. -

6 minutes ago, SuperStu said:

Not much to say TBH, enjoy the fame.

So it's a legit? Oke.

Mom! Mom?! I'm famous!!?

-

1

1

-

Uprev back to stock settings

in Performance

Posted

Back fire or after fire

You said that you have changed it over the years to stock, so you can tune it yourself?

Do you have wideband sensors? If so you can change the fuel, turn on decel fuel cut (if its off)