-

Posts

151 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

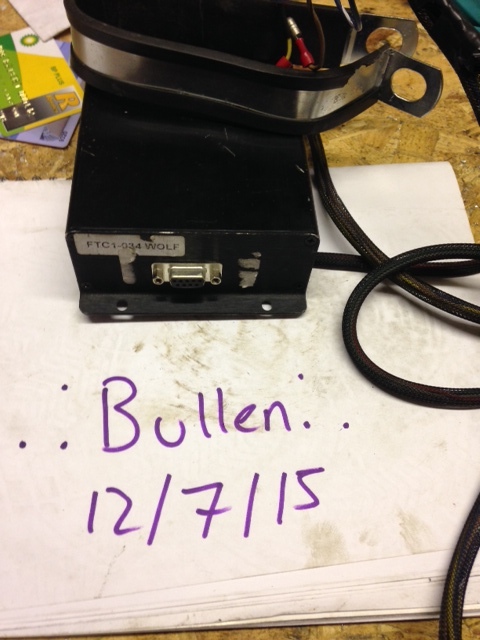

Posts posted by .:Bullen:.

-

-

Do it yourself with a dremel. Look for Jim wolf tech pics, they are the best if not I will be doing mine in the next few weeks.

If you don't mind taking some photos etc when your doing it that would be great

Sent from my iPhone using Tapatalk

-

Is it worth having the block machined slightly to fit the hr headgasket? Or just use s hks one for example

Oil pump will now be added to the list 😃

Sent from my iPhone using Tapatalk

I would modify block. We have 3 boosted Zed here all with modified block to fit HR gasket all works well

Sent from my SM-G850F using Tapatalk

Is it s simple request for most builders ? Any info pics etc on what's required ?

I've just managed to pick up a set of

Wiseco Pistons & Brian crower rods for an absolute steal so that's one piece of the puzzle.

Sent from my iPhone using Tapatalk

-

Is it worth having the block machined slightly to fit the hr headgasket? Or just use s hks one for example

Oil pump will now be added to the list 😃

Sent from my iPhone using Tapatalk

-

Just a 2005 de. It's the standard oil pump currently I wasn't aware there was any issues with it ?

Timescale isn't an issue its not a daily driver and I barely use it as is but looking to get more use from it and a few track days in next year. Budget wise obviously keep costs to a minimum really I will do most or if not all the work myself as I'm a qualified tech but peace of mind on a warranty for the engine would be nice. I suppose 2-3k ideally if I can pick up some bargains 😂

Sent from my iPhone using Tapatalk

-

1

1

-

-

You can always get a ready built package and take it to your local engine builder to stick it on, sell your OEM one

, either long or short.

, either long or short.See my previous post for packages.

Yeah I saw the kits but chances of finding someone to buy a bottom end are slim 😂

Plus should keep the cost down abit if I just have the parts replaced maybe

Sent from my iPhone using Tapatalk

-

Excellent appreciate the replies, next is any recommendations on who to build it and hopefully if they are localish to me on the east coast ha

Sent from my iPhone using Tapatalk

-

Hi all currently running a twin turbo set up and as always looking for abit more power now I know reliability will mean forging the engine.

Am I right in thinking basic stage 1 I suppose would be the following:

Weisco Pistons 8.8-1 ratio

Conrods maybe Brian crower or eagle

Arp head bolts

New gaskets etc

Anything else worth adding while I'm in there? I've seen people mention machining the bloke passages for the HR head gasket ?

Sent from my iPhone using Tapatalk

-

How did you get on with Ken?

I'm going to see him on Sat (i was supposed to be going Sat just gone but was out for my mothers birthday and too much wine was consumed)

I sounds like he'll be able to do it and the money seems good too though we only briefly discussed it, hopefully if all goes well with my meeting with him next Sat i'll get the work done with them. cheers for the heads up on that one dude

No worries.

I'm getting my bottom end fitted there.

What's he roughly charging if don't mind me asking? Is it drive in drive out ?

Sent from my iPhone using Tapatalk

-

It turns out was just the noise from the solid flywheel, once the revs rise it's not an issue. I did adjust the pedal but done it too low so I need to raise that back up again but other then that happy with the clutch kit so far

Sent from my iPhone using Tapatalk

-

I did a custom twin turbo build on mine a year or so ago, was based on the sts kit and well let's just say I won't be doing another one! Ha

Lots of late nights after work, problem after problem making something then, something else doesn't fit etc constantly harassing people on here for advice.

I also called in a lot of favours off friends but I did build it from scratch custom manifolds, downpipes, water & oil lines etc

The end result was worth it but there is a reason the labour rates on these are so much!

But I hope you factor all that in and if you go ahead the build is awesome ðŸ‘ðŸ»

Sent from my iPhone using Tapatalk

-

Yeah it was Clark Motorsport I have pinged them a email to see if they have any advice

Sent from my iPhone using Tapatalk

-

Hi guys just fitted the Xtreme twin plate clutch & solid flywheel. All went ok and bolted back together however the clutch pedal travel is now really high when biting and when it does bite it sounds as though its perhaps catching or sliping ?

Any ideas on how to sort it ive googled and read about adjusting the clutch pedal travel which i did wind out 2 turns but not sure that helped ha

Thanks in advance

-

Fancy selling the forged bottom end separately ?

Sent from my iPhone using Tapatalk

-

Haven't panned through the whole thread but I've recently finished building my twin turbo zed project. Did your bottom end blow ? Or just upgrading for more power ?

Sent from my iPhone using Tapatalk

-

It's going to be the next purchase, Would you recommend plumbing in the oil cooler same as normal fit a thermo sandwich plate. Then run the oil cooler from that ?

Sent from my iPhone using Tapatalk

-

Thanks appreciate the help, also you might know how accurate is the water temp oem gauge? It never goes above half normal running temp but I'm paranoid after putting so much work into the build for it to cook itself 😂

Sent from my iPhone using Tapatalk

-

To be honest I haven't plumbed in a gauge yet to see I was just thinking of eliminating high temps if I track it.

But the drain tank from the turbos is mounted just above the front brace so should be getting cooled and help.

I did think about the themo plate, but didn't know best route for plumbing it in.

I think first step is get a gauge sorted and check what temps I have

Sent from my iPhone using Tapatalk

-

Hi guys

I've got a low mounted twin turbo and was looking to fit a oil cooler. At the minute the oil return is out the turbos into a drain sump, then sucked back up into a scavenge pump before going back into sump pan.

My question is can I fit a oil cooler directly after the scavenge pump and then return it back into the sump?

Thus eliminating the need for sandwich plates and extra fittings etc

Sent from my iPhone using Tapatalk

-

Hi guys I'm in the market for a new clutch, I'm currently running 410bhp & about 360torque but I'm getting clutch slip now.

Any ideas what's good value for money & suitable upto about 500bhp so I have growth.

I have seen techniclutch online state good for 550bhp & for £300 anyone dealt with these before ?

Or if anyone has better options let me know appreciate the help

Sent from my iPhone using Tapatalk

-

I've just recently had one made, don't know the dimensions but the company will soon be advertising them for sale

Sent from my iPhone using Tapatalk

-

Hi guys, just finished building my twin turbo set up but looking for advice on the boost controller with external waste gates.

Got it mapped and set up by jez and I'm happy with the power but just browsing the set up of the boost controller & there's a few guides that show it goes from the vent port on top of the external waste gate?

Currently mine does not just looking if anyone knows the correct set up?

Thanks in advance

Sent from my iPhone using Tapatalk

-

-

7 if it was today as mines now finally back on the road after a long ongoing build ha

Sent from my iPhone using Tapatalk

-

Awesome there off the car so il just thoroughly clean them & hope & pray they are fine ha thanks guys

Sent from my iPhone using Tapatalk

Single Exits - Are they all absolutely deafening?

in Exhaust

Posted

I'm going to be selling my single exit in the new year.

Miltek y pipe & 3" straight pipe with 3" back box & 4.5" tailpipe.

If your interested let me know

Sent from my iPhone using Tapatalk