-

Posts

133 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by Lewis_UK

-

-

3 in 1:

New Exhaust

Rear Diffuser

Rear Spats

-

You guys/girls using the Titan Race Pro S mainly Snjur:

Snjur, you really using 10w60? How long you been on that weight?

-

PM Jon at Emperor Tuning, he was recently breaking a roadster that looked like it only had 1 good front ray after a crash.

http://www.350z-uk.com/topic/111647-breaking-for-parts-2007-350z-wv2-roadster-rev-up/

-

This is what I'm using:

NGK 6240 Laser Platinum: PLFR5A-11

No Turbo or Supercharger.

-

update.

Mechanic replaced my camshaft and crankshaft sensors.

It drove fine for 3 days, but today , car pulled back and the same dashboard lights came on (engine, ESP, skidding).

Plugged EOBD code reader in, it says P0340,

which manual says is "Camshaft position sensor A - bank 1 circuit malfunction"

which is same code from before.

any help/comments/experiences?

Hi Nic,

How much did you pay for the sensor/s?

Because I recently also fell foul to cheap aftermarket sensors which was not better than useless it seems.

It seems the OEM really are worth their value.

-

Sweet

I'm test printing now, I'm amazed at how hot you need to print to properly print in ABS. With PLA, a nozzle temperature of 160 and a bed of 60 is plenty!

I bumped this up to 190 and 90, and the ABS prints, but the layers don't stick together (but it did adhere to the bed! so the bed temp is good) so I bumped it up to 220 and it stuck much better, but still not perfect, so now trying another at 230! lol hot hot hot!

I will speak to my colleague tomorrow/friday in regards to temp of print, I think it was close to the 250 mark.

Not meaning to put a dampener on your idea Lewis/CS but it is a concern (imo) to the life expectancy of this part with it being constantly subjected to varying temperatures which may lead to part degradation.

I understand you are planning on using ABS filament which in itself has a better resistance to higher temperatures than PLA filament and although it does have good strength properties it is as yet a totally untested part in the environment you're putting it in.

Just airing more on the side of caution with the part itself being passed the filtration area for the engine meaning that if any break down of the part did happen, no matter how minor it would without doubt be sucked into the engine so anyone intending to fit these would need to be well aware of the "possible" risk they may be taking.

Also with regards to selling these on the forum cs2000 you would need to get in contact with glrnet (Graham) in order to re-open your trader status/account.

Thanks for you concern GM, I never considered this really. I naturally assumed that because of the temp required to mold the print, and the intake temps from the Zed, this would not be an issue.

I think I'm going to do daily checks to be sure. I did check today, all still solid.

-

Will that work with an Auto?

Don't see why not dude, you only use the throttle during ECU procedures.

-

1

1

-

-

Looks great CS2000,

Thats came out soo consistently, looks like bandage material ;p

Sent you a PM, let me know if you think any tweaks need doing, thickness/height/width etc

-

Where can I buy a code reader?

eBay, amazon.

-

I have a 3d printer and could knock these up, but its not my design so...

I give you full permission(and anyone else) to re-produce as you please. If that's what you mean.

EDIT: In fact, if this is something that gets going, I'm more than happy to make designs and convert to .stl for people to use if you give me dimensions/measurements and maybe rough picture etc.

Or a bigger/smaller Velocity Stack mouth. It will help build my experience on what can be achieved.

-

3

3

-

-

Good effort. Screw sanding it though, if you're using ABS, try acetone vapour smoothing. Just need a hot plate, some acetone (nail polish remover) and a glass beaker. Boil the acetone and the vapour cloud deposits and smooth out all the wrinkles.

Thanks I will try that.

How did you come up with the angle of the cylinder curve? Is this measured off the uprev stack or eyeballed?

You mean RevUp stack? This was all done by eye and basic measurements from the intake tube being 3" itself.

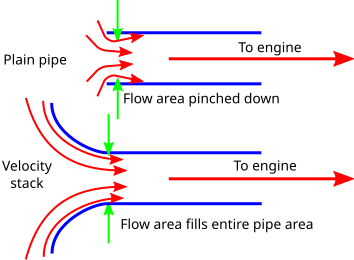

I searched the term "Velocity Stack" and found a picture on wikipedia:

So tried to go for that sort of angle.

-

Lewis PM how much please

David

I'm deeply sorry Dave, but this was more for infomration and innovation.

I think I would get in trouble from work if I started to supply and distribute.

Or the other hand, I will provide a link to the ".stl" file create, and you can go to a company with their own 3D printer, send them the stl file and they will give you a quote on printing and delivery.(Which will probably be naff all)

Example: https://www.3dprint-...load-and-quote/

EDIT: The website above just had alook properly, only do minimum order of £40, which this created is no where near £40, I would say less then £10 created+postage you could get it done, so dont use the website above tbh, just an example I found, loads of sites out there.

Another Edit: https://www.digits2w...sls-containers/

If you check that website it seems the going rate is about £40 for the container they charge you to use.

Material used: ABS 3D Filament

Current dimensions of my mod: Width/Length Cylinder Diamiter - Top: 101.6mm - Bottom: 76.2mm | Height: 25.4mm | Curved Angle: 150 Degrees | Thickness: 4mm

Their Container Size: White Standard £40: 110mm x 90mm x 25mm

Link to the .stl file: https://www.thingive...m/thing:1770224

Richtrix is my work colleague(he let me use the 3D Printer to produce) so was uploaded on to he's thingi account when we printed.

-

1

1

-

-

So unfortunatly flyboy recently run out of Velocity Stack mods, and because I have an UpRev coming up soon I decided to take matters into my own hands.

At work we have a 3D Printer(MakerBot) and we use AutoCAD 2016.

So after a few hours of playing with CAD and getting used to I had come up with this:

So my first attempt. As you can see the curve came out straight. Trying to munipulate CAD to produce a curved angle cyclinder, to also print out as a "3D Watertight Object" was challenging.

This is Version 3: (Version 2 was very similar but have a thickness of 2mm which came out very flimsey, V3 is 4mm and solid)

Real life result (Has currently been installed for about a week now and still holding strong):

A little bit rough here and there, but I think will a little bit of light sanding will be very smooth.

-

5

5

-

-

(Tocuh Wood) If/when mine needs doing, I think I will be going for the Xtreme SMF Clutch.

350Z DE Version: http://www.350z-uk.com/topic/86628-introducing-xtreme-clutch/ (Scroll down page abit)

350ZHR + 370Z Version: http://www.350z-uk.com/topic/92517-new-release-xtreme-clutch-kit-inc-smf-and-csc-solution-350z-hr-and-370z/

-

2

2

-

-

The place I got the Z from have finally started work on it by replacing the s/c for a genuine Nissan one. They've bled it & got it driving, but the pedal dropped halfway back down as it did with me last week, so they're now replacing the master cylinder on Friday when it arrives.

So far, I've driven the Z for 4 days, it's been sat n the garage for a further 6 days

.

.I remember reading a quote on this forum from a reptuable garage on here saying "no need to replace master cylinder as I have yet to see one fail".

Aslong as it's at their cost and not yours it's all good

-

Interested in the spacers + Panel filter.

Rough mileage on spacers?

And when you say hardly used filter, you mean it was used at one stage or?

-

What are the benifits over the plenum spacer ? what sort of bhp would it give ?

http://www.kinetixracing.com/kinetix_350Z_and_G35_intake_manifold.aspx

+30.5 According to photo.

-

Whats the standard on Nismo exhaust bore?

Militek 3" bore.

But shouldn't be a problem either way, people also like the motordyne xyz.

-

1

1

-

-

Do you use a "Performance" oil filter?

What oil weight?

-

Update.

The car drove onto the recovery truck this morning, obviously cooling down overnight helped, it was also driven off. It's at the place I bought it from & they've agreed to do the 3 repairs I asked them to do initially, the extra one being the slave cylinder. I even emailed them a couple of guides as you can't trust everyone

.

.They're re-painting the front bumper as there's a small amount of damage at the bottom, they're also finding out what the source of the knocking is from the front suspension. I suspect the banana arms? They'll check it though.

I want my Z back

.

.You've had a very nice turnaround, and to be fortunate about the trader you brought from being respectful and helpful towards this situation.

You'll be getting an ever better car than you started, for nothing extra.

Just be thankful it happened now and not after 6 months

Always look at the positives and I'm happy it's all getting sorted for you.

-

Dirty MAF? Dirty TB?

-

1

1

-

-

Alex has literally just been relying to another member about clutches,

see here: http://www.350z-uk.com/topic/111192-clutch-replacement-and-flywheel-traders-on-here/

-

Well worth the money whoever buys, best purchase I ever made, if not just for structural rigidity.

-

2

2

-

-

Evening guys,

I know some people frown upon Japspeed parts etc, but for those who take the plunge like myself just to "give it a go" I come baring news.

Some of you already know Japspeed use the 2fast2cool alias on eBay for their parts, but strangely mark it down cheaper.

Turns out theres more.

I went to buy a K2 Japspeed Exhaust and this is what I have found:

Japspeed official eBay for K2, £331.55:

Japspeed alias performance-motorsport-parts, £299.99:

Japspeed alias 2fast2cool, £289.99:

Japspeed alias uk-performance-uk, £229.99:

I myself brough from uk-performance-uk being the cheapest, as you can see from pictures and description, no mention of Japspeed. Got delivered today, Japspeed logo are on there.

performance-motorsport-parts, 2fast2cool and uk-performance-uk use this address:

Barry Scott

Units 2, 3 + 4 Southern Ind Est

Southern St

Manchester

Lancashire

M28 3QN

United Kingdom

Japspeed:

Jap Speed

Unit 19 Oakhill Ind Est

Devonshire Road

Walkden

Lancashire

M28 3PT

United Kingdom

Just making this post to make people aware, as you'll proberbly end up paying more for the same parts, just different sister companies.

Should 1 side of the exhaust hang lower than the other?

in 350Z General

Posted

Seems to be a common problem, I had EXCATLY the same.

I originally thought it was my exhaust hangers, now have a new exhaust and its ALMOST perfect, still out thought.

But do check rubber exhaust hangers/the metal brackets they hang, could be rusted/bent.