Moynesey

Members-

Posts

14 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Everything posted by Moynesey

-

Tarmac spec Stage rally car - fresh build

Moynesey replied to Moynesey's topic in Member Build Projects

Hi Woodzman, Thank you for the post, I am really happy with the cage install. My friend owns a metal fabrication business and did a superb job for me. My brother runs a BMW E36 328i stage car and we’ve run a few other cars previously, we often do Bovington etc but auK rallies are getting harder and harder to find. We have serviced a fair few times out in Belgium and run on the Monte Berg rally in 2019. We had planned a few Belgium events this year but as we know they all got canned! We did manage a run on the Cotswold Stages but it would have been better in a submarine! The 350z is being built to FIA Regs even if it does get an MSUK log book and is intended for Belgium tarmac events. To be fair I have always wanted to build a 350z after seeing them run in the 350z abroad but it’s only this year that has seen the MSUK create a category for production cars with engines larger than 3000cc multivalve. Unfortunately the Cat 3 rules to limit the amount of mods but that’s also good for the bank account lol. As for final drive, I am looking at a 4.3 with a plated slipper, want to get it into the 115-120mph max territory plus lighten the flywheel etc. your boss has some serious toys, we’ve probably made up the numbers on some of the same rallies he will be at the front of lol -

Tarmac spec Stage rally car - fresh build

Moynesey replied to Moynesey's topic in Member Build Projects

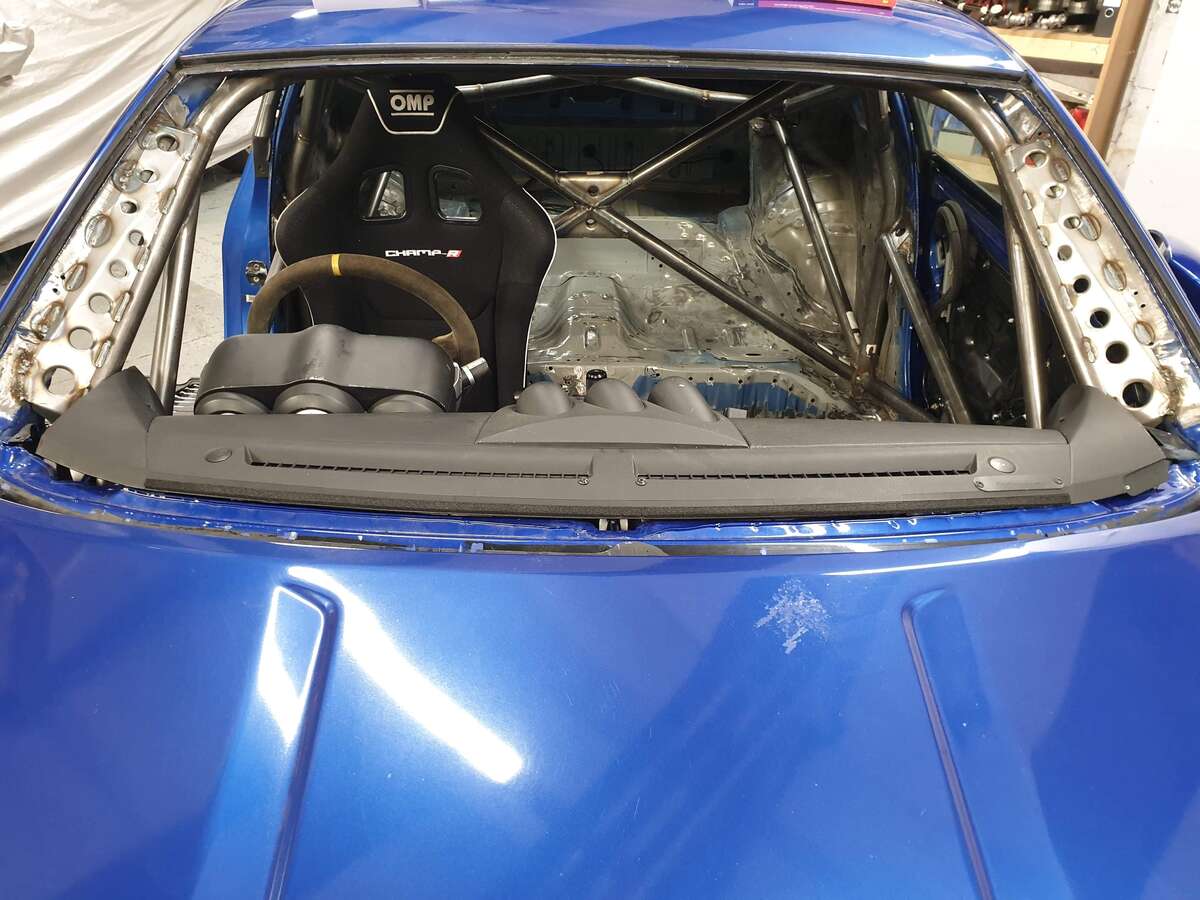

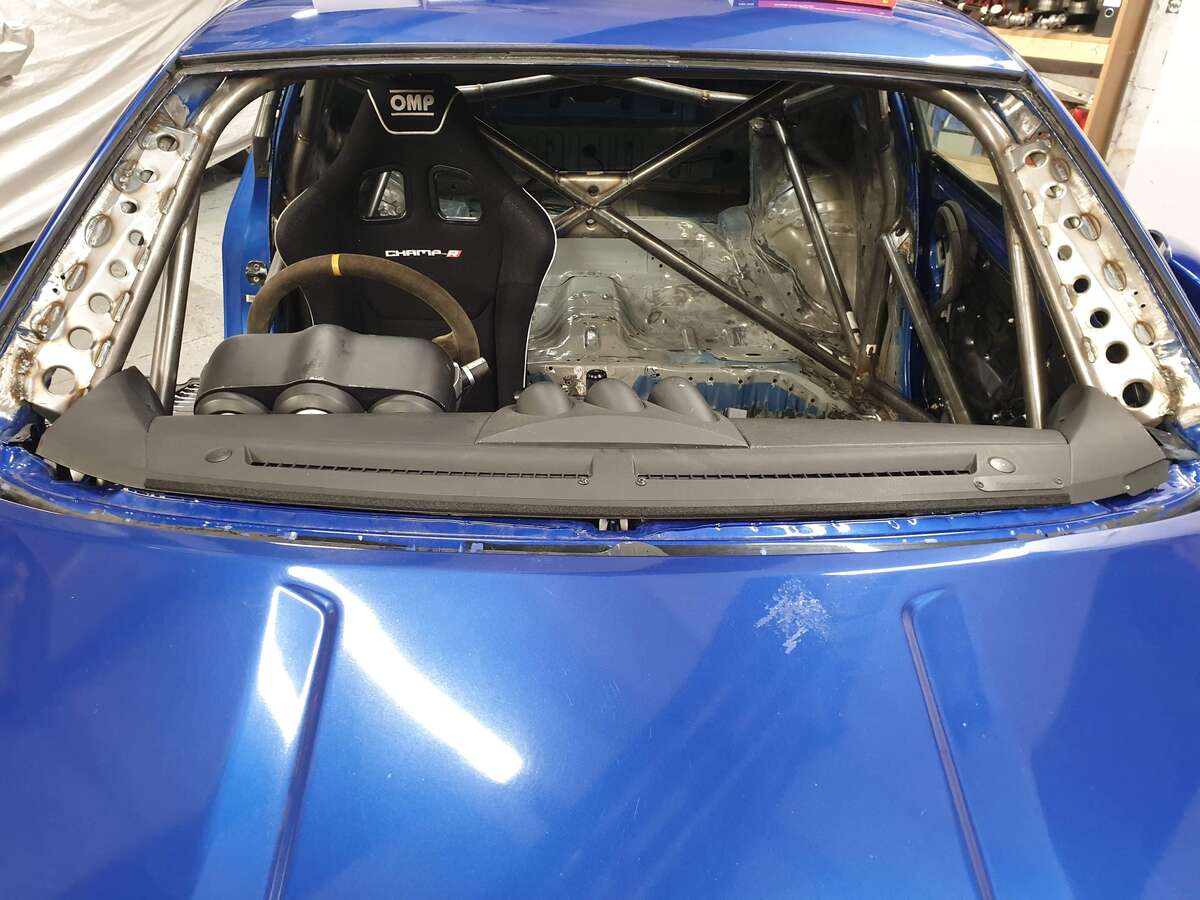

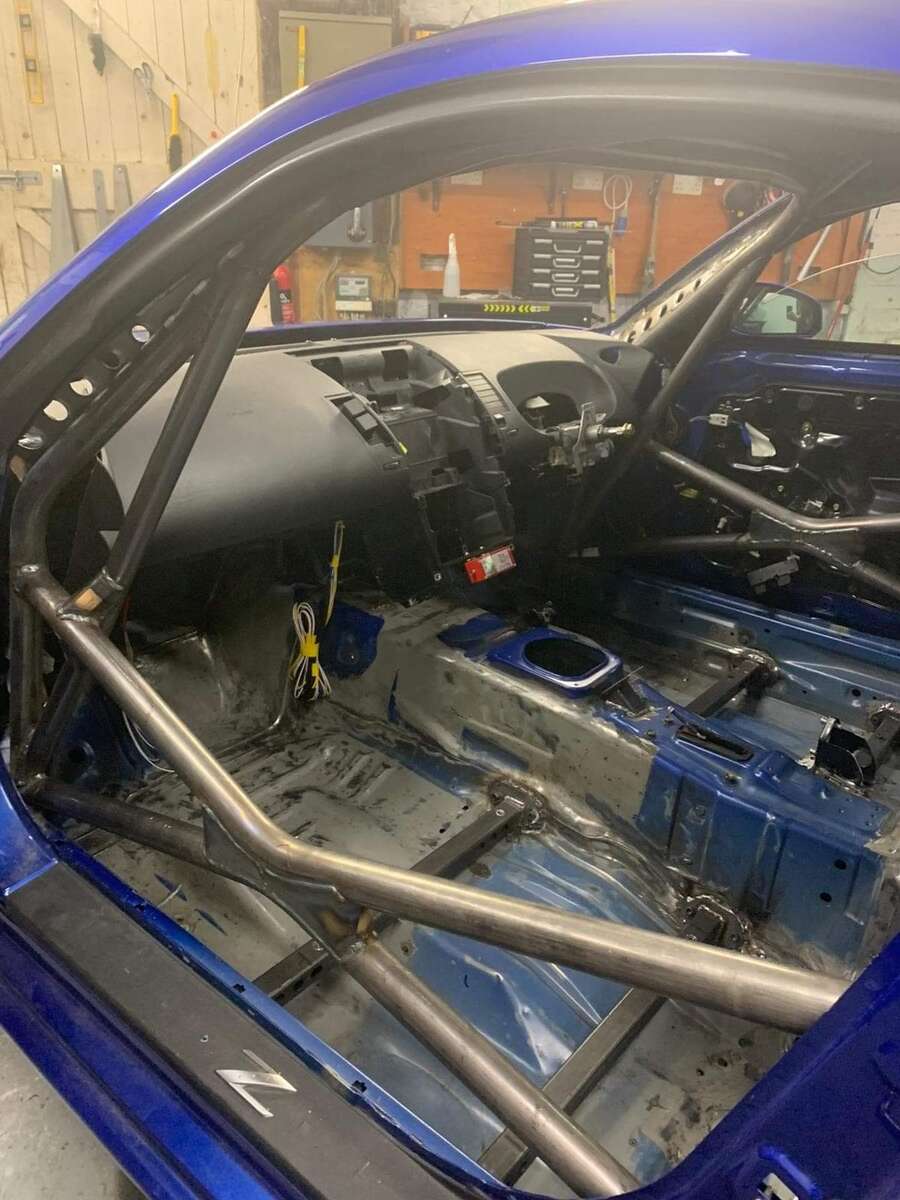

So this weekend was set as the big push on the interior, final welding, masking up, primer, flat off and shot the colour.....and we managed to get it all done! The car can now sit and harden this week before the reinstall starts finally. New seats and harnesses on order and dash has gone away for its flock finish. starting to look like a rally car and not a half baked project. -

Tarmac spec Stage rally car - fresh build

Moynesey replied to Moynesey's topic in Member Build Projects

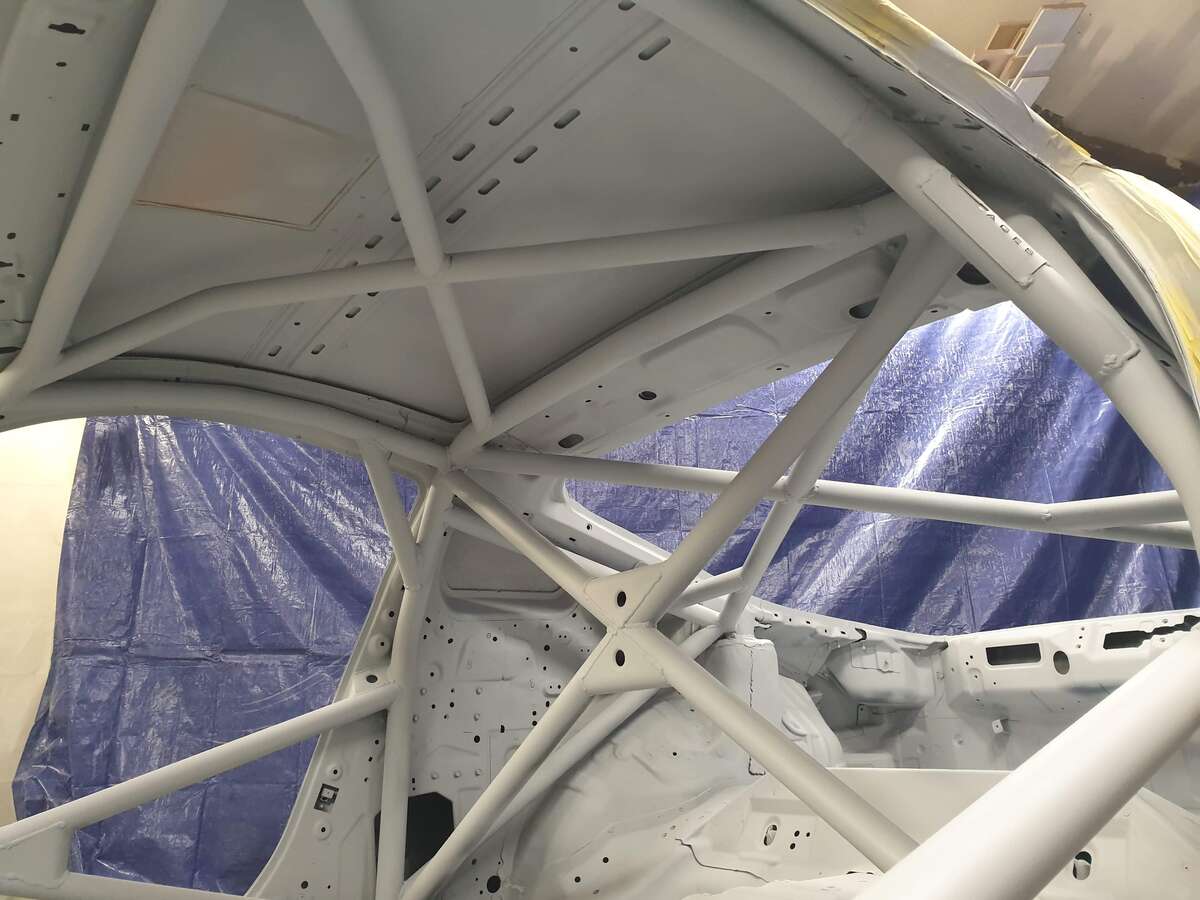

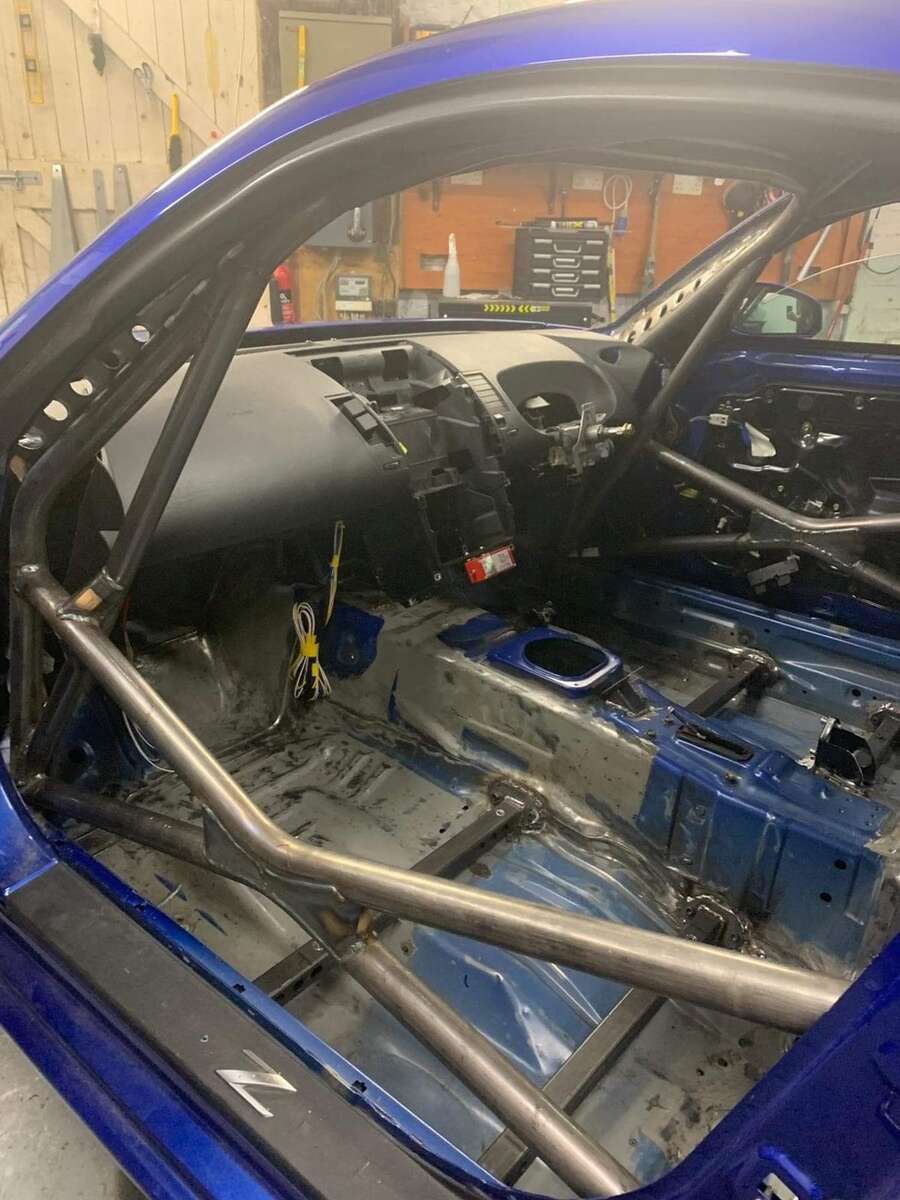

Hi all, Sorry for the radio silence, between CV19, starting a new full time job and my pro welder fitting in the cage between random work it been a long couple of months......however....... * The full weld in multi Custom Cage is in * Floor cut away and FIA seat rails in (A little more welding to be done by us, my welder mate only did the cage) * Captive threads welded in to hold the plumb in extinguisher * Dash cut down and altered (ready to be flocked) * Race heater mounts welded in * Hydro handbrake brackets welded in and the set up modified. * Doors stripped ready for Perspex * Most of the wiring loom thinned out but the dash one went a little wrong The interior metallic effect grey 2 pack paint is waiting patiently on the shelf, hooding to start the paint prep this weekend and a big box of goodies are en-route. Spoke to Motorsport UK about the door card regs to explain that the original door cards are never going to work and if cut down will be useless, they have agreed and allowed for flat panels to be installed, yay. -

Tarmac spec Stage rally car - fresh build

Moynesey replied to Moynesey's topic in Member Build Projects

Hey, I haven’t made a finally decision on which LSD I will be running yet, it will obviously be a plated type and not a helical one but exact model TBC. Sorry to everyone for the lack of updates, I will get some up this week, there has been a fair bit going on. -

Tarmac spec Stage rally car - fresh build

Moynesey replied to Moynesey's topic in Member Build Projects

Just realised what I said, been a long day. The original handbrake must stay for MOT and scrutineering, the hydro handbrake will break into the rear brake lines and operate the rear calipers, it’s has nothing to do with the hand brake shoes. -

Tarmac spec Stage rally car - fresh build

Moynesey replied to Moynesey's topic in Member Build Projects

A lot of bits have been done the last few days, in summary... * Test fit of thinned out loom, a few niggles but within a few hours everything was sorted and fully working. * Front panel has been cut down to allow more airflow and ease of removal. * Due to the above, a new radiator mount was fabricated from scratch, old rad used and will be replaced. * New central bar for mounting the oil coolers * HEL Performance oil cooler kit installed, thanks to the guys at HEL, great product. * Uprated power steering cooler and lines installed * Front bumper mounts modified to allow the entire front to come away in minutes. * Reassemble to check all is ok with everything installed. * Mud flaps fitted As per MSUK regs. Looking forward to the cage arriving to get things really moving. -

Tarmac spec Stage rally car - fresh build

Moynesey replied to Moynesey's topic in Member Build Projects

At the moment the rules don’t allow for any changes to the base braking system so it will be standard for now and I’ll see where we get to once i get to that part lol -

Tarmac spec Stage rally car - fresh build

Moynesey replied to Moynesey's topic in Member Build Projects

Yep, waiting for a new tandem cylinder one to arrive. After sitting in position with eyes closed and feeling for a natural position, I have decided it will be fitted in the space between the gear stick and steering wheel. We had a great weekend on the car, I will put the updates up tomorrow. -

Tarmac spec Stage rally car - fresh build

Moynesey replied to Moynesey's topic in Member Build Projects

After a week of getting a few boxes in the post, it was time today for some trial fitting and starting to map out the interior locations. Firstly the Coolerworx short shifter arrived and what a lovely piece of kit, well made and a great company to deal with, thanks to the crew at Coolerworx. The throw is so close it was quite unbelievable, a flick of the wrist is all that you require to snick through the gate. The NRG boss arrived and so the Sparco wheel was put on to check the feel of the driver controls in relation to each and settle on a final location for the hydraulic handbrake - tandem cylinder style one is on order. Mocal cooler collected from the guys at Matt Lewis Racing #mattlewisracing - cheers Matt. It nice good to meet you the other day. This cooler will be used to replace the OEM power steering cooler. First on the carbon sheets were cut and brackets fabricated to locate the intercom, electric fire extinguisher button and cut off (lost the cut off button! Yep, on order lol), tomorrow I will hopefully get the upper panel first fixed ready for the aux switch/circuit breakers. Once it’s all complete the dash will come out during the cage installed and be flocked apart from the Carbon panel faces. Fingers crossed the cage will be with us in a few weeks and we can get that installed to really get things moving. Most locations can’t be set until that is positioned. -

Tarmac spec Stage rally car - fresh build

Moynesey replied to Moynesey's topic in Member Build Projects

There is a power to weight regulation that requires an air restriction if you go above a certain level based in the manufacturers declared wight. I think even with the cage in there will be a slight weight saving. As for the panels, some can be changed and that may come later but for now it’s about getting it stage ready and then develop certain Areas later. These cars tend to be 1400kgs in stage trim as an average, that’s not a huge weight when you consider a stage Mk2 escort is around 1200kgs, e36 M3 is around 1400kgs etc Not many cars offer 300bhp RWD for such a good price these days. Once it is built I will get it on the scales and see where we are -

Tarmac spec Stage rally car - fresh build

Moynesey replied to Moynesey's topic in Member Build Projects

Just a few photos from today. The interior is now ready for a paint dusting pre weld in cage. Managed to get the rear rear spoiler off, what a mission that was in readiness for the v1 spoiler, also cut away a fair amount of the under metal from the boot lid. Quick test fit of the dash top only to see what can be chopped off, already cut away the lower section of the centre console tower. You can see the intercom held in place to see what it’s like, carbon fibre sheet ordered to make the switch panels. Removed all the front wheel arch liners, nice to see no actual rot still, smothered everything in WD40 in readiness for the suspension strip and replace. Measured and planned out the lower radiator mount and Sump guard mounting bar, coming soon once the metal arrives. Wire looms are getting smaller lol, the rear one in holy taped back up and it tiny now, mid one is in progress and the it’s the dash one. -

Tarmac spec Stage rally car - fresh build

Moynesey replied to Moynesey's topic in Member Build Projects

Good evening everyone, Today saw myself, brother and 2 great mates really get stuck into the internal metal work today. The final parts of the rear metal work have been removed and cleaned up, all seat box sections had the spot welds drilled out and removed (thanks guys you know who you are), almost all the sound deadening removed and cleaned up. At which point I finally I gave the whole area a good run over with the grinder wire bush. For the eagle eyed, I haven’t quite finished the driver footwell because we still have to cut out the section of transmission tunnels that randomly juts out to ensure the seats can be set low enough. Interior space is almost ready for the weld in cage which hopefully will be inbound in about 2 weeks. Going to start the reinstall and modifications to the radiator area tomorrow, Hel Performance oil cooler kit has been ordered and I will post up the details when it arrives next week plus today we figured out which cooler I am going to us for the PAS. Also waiting for the Coolerworx shifter to arrive, got to have a few nice bits to look at while you plough through the mundane clean and prep work. I have received some great service from the guys at Coolerworx so far and look forward to installing the shifter. Great to see the metal work is in superb condition under everything. The wiring has continued its thin out process and once completed, I put up some photos of how far we got, cheers Jk. Hopefully in a few weeks there will be some more interesting bits to talk through lol -

Tarmac spec Stage rally car - fresh build

Moynesey replied to Moynesey's topic in Member Build Projects

Just a quick note, here is the pile of wiring already removed from the rear and central loom section. The look running through the dash is next, the eng8ne loom will be left alone currently. fingers crossed once a lot of items are removed from the ECU map it will start again with this thinning down lol -

After posting on the 350z page on Facebook, I have been asked to start a build thread. I thought I’d say hello and let you into my latest project. I am new to the world of Zeds but with the new 2020 Cat 3 regs being introduced but the MUK for rally cars with larger than 3.0 multi valve engines, I decided a return to rallying was in order. Always fancied a 350z ever since they were released and a tarmac rally one is even better. After a little hunt through a load of tatty rubbish I found a blue 2006 Revup about an hour from home and picked it up 2 weeks ago. So far the entire interior is gone apart from the steering column, all the unwanted metal frame work for the subs etc has been cut out, wiring looms removed and being ‘thinned out’, front removed and all heater/AC kit removed, bonnet pins in and ext cut off/fire switches fitted. AST coilovers and a few other bits are waiting on the shelf. Custom Cages T45 multi point weld in cage has been ordered and should be here in 3 weeks and a shopping list has been started. I already have a lot of motorsport parts on the shelf due to previous build and have ordered this week a Coolerworx shifter (original gearbox has to be used) and a HEL Performance oil cooler kit. Cat 3 regs are quite strict so only a certain amount of modifications can be made. I’ll post a few photos etc as I go if anyone’s interested. This is just the strip out stage and a few bits added, I will start to take some more detailed photos as we begin to build the car.